Automated Vision Systems Bolster Food Inspection

Various configurations of illumination, sensors, and cameras enable compliance while monitoring product quality and safety before shipment.

By Hank Hogan

As the demand for quality food increases, producers are striving to hit the sweet spot of the market between nutrition and value. On top of this challenge, a variety of regulatory requirements associated with food production and sustainability must be met. Given all these market factors, food and beverage producers are implementing advanced vision systems to aid in the inspection and monitoring of products throughout the process, from the receipt of bulk product to packaging. These systems incorporate fast cameras, specialized sensors, advanced lighting, and targeted artificial intelligence (AI) algorithms.

With hyperspectral imaging, food inspection vision systems can determine the ripeness of fruit. An image of pears (right) and the hyperspectral estimate of the fruit’s ripeness (left). Courtesy of Headwall Group.

End-user demand has resulted in substantial growth in the deployment of automated inspection systems. According to analysts at Verified Market Reports, the global inspection systems market for food and beverage was valued at $4.1 billion last year and will grow to $7.5 billion by 2033, with a compound annual growth rate of 7.2%. Machine vision systems employed in food and beverage inspection have been a major driver of the market, particularly in North America, due to consumer expectations for quality

assurance.

Fabien Dubois, who previously worked at a food-sorting system manufacturer, is now an applications engineer at ProPhotonix. The company provides specialized lighting solutions to vendors, including those in the food-sorting industry. Automation is a key factor driving machine vision adoption with minimal variables in the process, Dubois said.

“Customers want to move to what they call dark factories,” he said.

“Basically, no human interaction —

they run themselves 24/7 with a

skeleton crew.”

Facilitating this paradigm shift in

the industry has required the increasing enhancement of sensor capability. Sören Böge, head of 2D Product Systems at Basler, pointed out that

the sensors in vision systems today offer higher resolutions, faster frame rates, and better sensitivity, even under challenging lighting conditions. These technological advancements allow for more accurate defect detection and quality analysis, even at high line speeds. For example, 5GigE technology systems can run a 12-MP camera at >40 fps, while GigE technology systems only allow 5 MP at 20 fps, he said. Thus, the more recent technology provides 2.4× the resolution at double the frame rate.

“This means higher throughput and more detail in inspection,” Böge said.

Camera speeds are increasing, Dubois said, with megahertz line-scan cameras released this year. This fivefold increase in speed requires brighter illumination due to the shorter exposure times. Food and beverage inspection customers require adequate lighting to highlight the spectral differences between good and defective products. They also want to differentiate the product from contaminants and the background. During the examination of items, a vision system captures diffuse reflection off an object, and attaining enough contrast and signal is critical.

“Most people say to us, ‘the more light the better.’ We’ve never communicated any upper bound,” Dubois said. One reason lighting limitations are not discussed in such conversations is that solid-state illumination causes less waste heat, so more intense light does not lead to overheating.

Brix is a measurement of the taste of tomatoes. Hyperspectral imaging enables Brix assessment and tomato grading. Shown is a visible image of tomatoes with estimated Brix values (left) and a color-coded image of the estimated Brix

measurement below. Courtesy of Headwall Group.

The intensity of the light is not the only factor to consider; delivery is also important in food inspection applications. High-output strobed lighting enabled by solid-state technologies can improve food and beverage quality checks, according to Mark Kolvites, technical sales manager at Metaphase Lighting Technologies. “High-output, strobed LED illuminators make it possible to capture sharp, blur-free images of fast-moving food and beverage products and containers, enhancing inspection accuracy,” he said.

The use of spectral imaging

Beyond the increased speed of modern inspection systems, another trend in the development of advancing vision capabilities is the use of spectral imaging, which captures multiple wavelengths and has the potential to reveal details in a product that traditional food inspection systems could miss. Food and beverage products have a spectral fingerprint that distinguishes them from inorganic objects and differentiates them according to quality.

For example, coffee beans and small dark pebbles look alike in the visible range but differ clearly from one another in the shortwave infrared (SWIR) wavelength range at 1450 nm. Water absorbs light at this wavelength, and since a coffee bean contains water while a pebble does not, absorption at 1450 nm can help detect and eliminate pebbles and other inorganic contaminants from a batch of coffee before it is packaged.

An added benefit is that machine vision inspection systems that operate in the SWIR range can look below the surface of food. This enables bruises or bad spots to be detected, as well as attributes that may not be readily visible under visual inspection alone.

Because certain wavelengths can pass through specific materials, SWIR imaging can look inside opaque containers to check liquid fill levels. SWIR technology can screen most plastics and glass for quality control purposes, according to Böge.

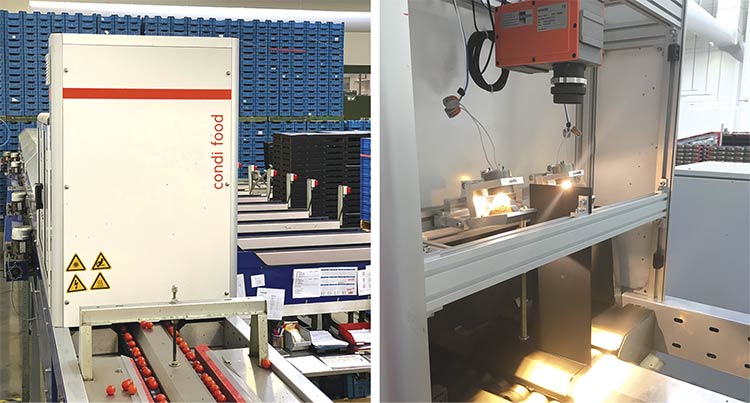

Condi Food uses hyperspectral Brix measurement to grade cherry tomatoes for taste in as little as 30 ms per tomato. Courtesy of Specim.

SWIR inspection can also be useful for grading food and beverages into different classifications for marketing purposes. Such categorization allows suppliers to sort certain products into a premium group — such as sweeter fruit, which can fetch a higher price — and other products into categories that sell for less.

Grading products and examining subsurfaces requires analyzing details drawn from more than one wavelength, though. This level of detail has led to the deployment of multi- and hyperspectral systems for inspection applications. The latter captures tens to hundreds of bands that uniformly span an entire spectral range. The IEEE P4001 standard defines a hyperspectral camera as one that covers at least 30 contiguous spectral bands lying between 250 and 2500 nm. In contrast, a multispectral camera images a smaller number of bands, often 10 or less, and large gaps could occur between those bands.

Of the two, hyperspectral imaging (HSI) is more expensive and demanding in terms of both sensor and lighting requirements, as well as data processing. It also typically runs at a lower frame rate. However, hyperspectral imaging enables more specialized capabilities for inspection.

“By capturing data across a wide spectral range, HSI can detect internal defects, measure moisture content, and assess ripeness or spoilage levels,” said Oliver Grass, managing director at inno-spec, part of the Headwall Group. “For instance, in fruits and vegetables, HSI can identify bruises or internal decay not visible externally.”

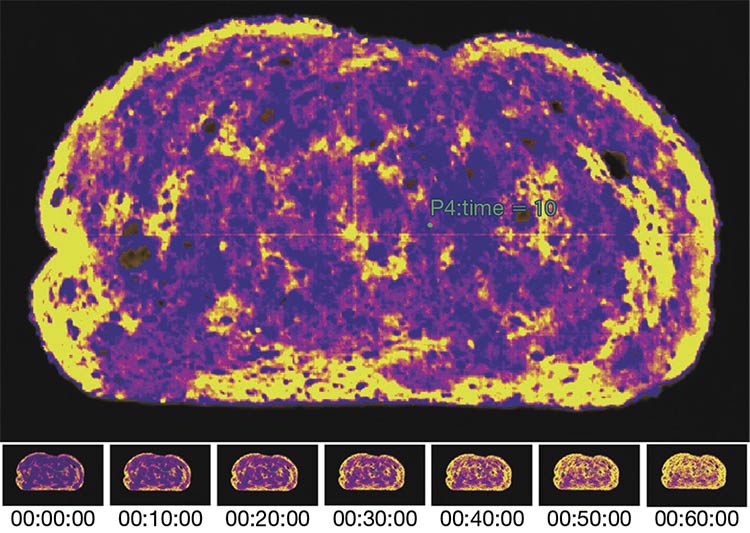

Hyperspectral inspection of baked goods for moisture, indicating moist areas (purple) and drier regions (yellow). Courtesy of Headwall Group.

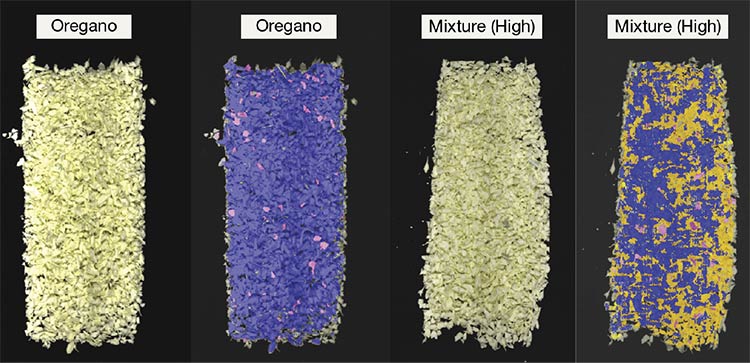

He pointed out that Brix measurement, which determines a scale of soluble solids, such as sugar, is the standard for assessing tomato taste quality. Traditionally, determining Brix involves a destructive test. Hyperspectral imaging enables a nondestructive in-line, high-speed Brix assessment, allowing producers to sort tomatoes according to taste. Additionally, using hyperspectral food inspection, producers can gauge the water content of baked goods or spot adulterations added to oregano and other herbs and spices.

Minna Törmälä, head of global marketing at Specim — Spectral Imaging Ltd., said that hyperspectral imaging can measure the sugar, protein, or fat content of products. This evaluation of food composition offers significant advantages compared with alternative approaches, she said.

“HSI enables safe, radiation-free, and detailed analysis without the need for physical contact or destruction of the sample. This is crucial for the food industry,” she said.

Hyperspectral imaging can identify contaminants such as mold, foreign

objects, and pesticides, Törmälä said. Detecting the last category is of growing importance due to regulatory pressures to reduce and eliminate pesticides in products sold to the public. Europe, for instance, is implementing more stringent rules on pesticide residues on food.

Ideally, the necessary lighting for hyperspectral cameras provides uniform illumination across all spectral bands. In the visible range, this is accomplished using multiple LEDs. In the infrared range, the broad spectral output of solid-state devices makes it easier to produce uniform illumination with LEDs.

“When you’re looking at 1450 or 1550 nm, those LEDs can have a full width half maximum of 100 or more nanometers. So, they’re naturally very broad,” ProPhotonix’s Dubois said.

The incorporation of AI

A third development driving advancements in machine vision applications is the creation of AI algorithms that improve image analysis and other aspects of the inspection of food and beverages. Böge said that food products have natural variations — differences in size, shape, texture, and color. Equipped with machine learning and deep learning — which uses neural networks — systems trained on suitably comprehensive image sets can recognize acceptable categories of food and beverages while still identifying subtle defects during the inspection process.

Unscrupulous suppliers sometimes mix oregano with olive, myrtle, sumac, and other ingredients. Hyperspectral inspection of spices can detect such adulterations. Courtesy of Headwall Group.

“This flexibility is critical in food inspection, where products rarely conform to exact shapes,” he said.

AI aids manufacturers today in tasks such as distinguishing individual items, including seeds, in a product stream. In the near future, vendors will increasingly incorporate AI where decision-making happens, such as at an inspection point, Böge said.

AI can also help less expensive vision technology achieve results comparable to more costly systems in specific applications, Dubois said, citing area-scan cameras and illumination as examples. Area-scan cameras paired with advanced AI algorithms can be deployed to match food-sorting results similar to those from a line-scan camera, albeit at a lower sampling rate, he said. For market sectors where price is a main driver and achieving the highest speed is not critical, this lower-cost solution could be important for maintaining a sustainable inspection process.

A second way AI could be incorporated to make less costly technology competitive for specialized inspection is in conjunction with multispectral imaging, which can generate results similar to those achieved with hyperspectral imaging. Dubois noted the availability of SWIR multispectral cameras, which enable the functional equivalent of HSI analysis to be performed in certain settings. By augmenting multispectral technology with AI algorithms, users might achieve the required inspection performance for a given application at a lower cost than HSI.

Looking to the future, inno-spec’s Grass predicted increasing use of AI in the analysis of hyperspectral imaging, with this integration leading to more autonomous and intelligent food and beverage inspection systems. Along with the continued miniaturization of sensors enabling portable imaging systems, these innovations will help with on-site quality assessments, even in remote locations, he said.

Ongoing advancements in machine vision — such as spectral imaging, imaging resolution, and camera frame rates — along with innovations in lighting delivery, will aid in capturing the information AI algorithms need for inspection analysis. Producers believe this combination of instrumentation and software will make it easier for food and beverage companies to deliver quality products at the right price.

Published: September 2025