A miniaturized near-infrared (NIR) sensor for industry, agriculture, and other sectors is ready to be deployed, according to its developers at the Eindhoven University of Technology (TU/e). The sensor’s design is based on an approach to spectral sensing that simplifes hardware requirements and supports the monolithic integration of sensors. The device has 16 different detectors, all sensitive in the NIR wavelength.

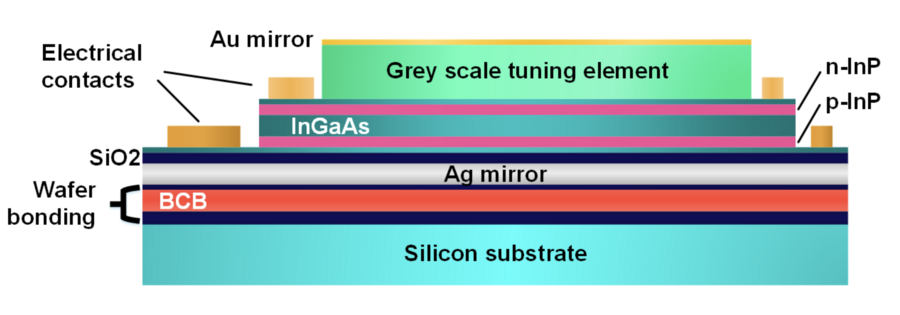

The researchers used an array of resonant-cavity-enhanced (RCE) photodetectors, each featuring a distinct spectral response in the 850- to 1700-nm wavelength range, to build the sensor. Based on the responses from the photodetectors, the team builds predictive models and is able to bypass the need for spectral reconstruction — instead, it sends the signals generated by the sensor straight to analysis algorithms.

Normally, when a sensor measures light, the generated signal is used to reconstruct the optical spectrum, or optical fingerprint, for the material. Sensing algorithms are then used to analyze the data. In their approach, the TU/e researchers skip the intermediate step of spectral reconstruction and use the signals from the detectors to directly train a model for the sensing problem at hand.

“This significantly simplifies the design requirements for the device,” professor Andrea Fiore said.

The streamlined approach lessens hardware requirements, leading to a more compact sensor design.

“Measuring the spectrum in the infrared is most interesting for applications in industry and agriculture, but there’s one major issue — current near-infrared spectrometers are just too big and expensive,” researcher Kaylee Hakkel said. The TU/e NIR spectral sensor fits onto a chip and in the future could even be embedded in smartphones.

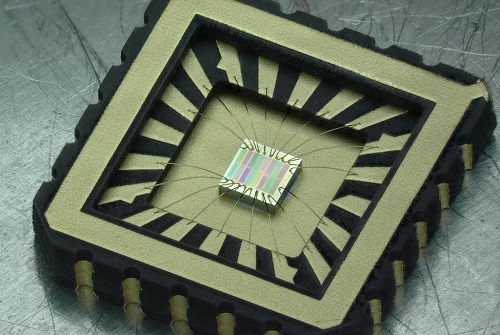

A miniaturized near-infrared sensor developed by a TU/e research group could fit in a smartphone and could be used to analyze the chemical content of food and plastics. Courtesy of TU/e.

In addition to being compact, the NIR spectral sensor is mass-manufacturable. The researchers designed a new wafer-scale fabrication process to miniaturize the sensors while keeping costs low.

In tests, the researchers gauged the sensor’s ability to measure the chemical content of milk and plastics. The sensor array accurately predicted the fat content in milk, despite measuring a much lower number of variables compared to a traditional spectrometer.

The researchers also used the miniature spectral sensor to classify different types of plastic. They evaluated 48 samples belonging to four plastic types. Using an optimized analysis model, the researchers obtained 89.6% accuracy in cross-validation of the calibration data set and 94.9% in prediction of the test data set. They believe that prediction results could be further improved with optimization of the technology and the pixel design.

“We used the sensor to measure the nutritional properties of many materials including milk,” Maurangelo Petruzzella, TU/e researcher and managing director of MantiSpectra, said. “Our sensor provided comparable accuracy in the prediction of fat content in milk as conventional spectrometers. And then we used the sensor to classify different types of plastic.”

The sensor’s size, which is similar to a smartphone camera image sensor, its ease of fabrication, and its robust structure may make it a good fit for portable sensing applications for industry and consumers. Many components that can be detected by commercially available spectrometers, such as sugar, starch, fat, and protein, present relatively broad spectral signatures in the NIR and can potentially be detected using an array-based spectral sensor, such as the TU/e sensor, that is optimized and tailored to the application.

Cross section of the sensor. The researchers used an array of resonant-cavity-enhanced (RCE) photodetectors, each featuring a distinct spectral response in the 850- to 1700-nm wavelength range, to build the device. Courtesy of Kaylee Hakkel.

The miniature spectral sensor could be applied in many areas where NIR spectroscopy has demonstrated its potential.

“We anticipate that the sensor could be used for personalized health care, precision agriculture (monitoring the ripeness of fruits and vegetables, for instance), process control, and lab-on-chip testing,” Petruzzella said.

The sensor is ready for immediate use; startup company MantiSpectra, a spinoff from TU/e, continues to work to advance its capabilities and market the offering.

“We now have a full development kit available based on this technology, the SpectraPod, that companies and research institutes are using to build their applications,” Petruzzella said. “And the great thing is that this sensor could even be commonplace in the smartphones of the future, meaning that people could use it at home to check the quality of their food or check aspects of their health.”

The research was published in Nature Communications (www.doi.org/10.1038/s41467-021-27662-1).