About This Webinar

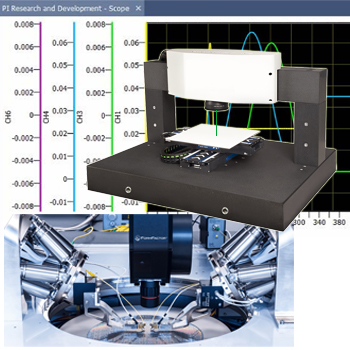

This webinar will present the latest advancements in precision motion control techniques, system architecture, software, algorithms, hardware, and mechanisms for system designers in the laser processing, optics, and photonics industries. The focus is on rapid implementation and minimizing total cost of ownership.

Part I: Photonics Device Test and Manufacturing

With photonics device manufacturing needs exponentiating, device and process engineers need to understand the latest high-throughput precision positioning tools that have emerged to support test and assembly of these devices.

Examples include:

- Test and assembly of photonics devices distributed over large area substrates, carriers, and trays.

- Newly developed technologies for fast localization, optimization, and tracking of devices.

- Autonomous microrobotic and precision-positioning solutions for fast optimization in the manufacturing of silicon photonic, laser electro-optic, lidar, and imaging-optic assembly and testing.

- Comprehensive, scalable industrial solutions addressing applications from wafer to final assembly.

Part II: Ultrafast Laser Materials Processing of Transparent Materials

Ultrafast lasers are becoming increasingly accessible to researchers and system integrators. Advances on the laser side are met with innovative motion control and nanopositioning solutions for disruptive next-generation processes.

Examples include:

- Common motion requirements of ultrafast laser materials processing in transparent media and how to optimize directly from CAD models.

- Working directly from DXF, STL, and G-Code to laser synchronized motion code.

- Enhancing throughput with application-specific trajectory path optimization and advanced tools for path modifications.

- Improving tracking errors on curvilinear paths through dynamics and real-time disturbance attenuation.

- Motion synchronized laser control for best process performance/throughput.

Who should attend:

Engineers and scientists working with optics, photonics, or laser processing applications and looking to improve throughput and quality. If you need to develop a better process or higher-quality systems with a reliable partner that can support your business globally, you will benefit from this webinar.

About the presenters:

Scott Jordan is head of photonics for PI and a PI fellow. A physicist with an MBA in finance/new ventures, Jordan has made multiple contributions to photonics alignment automation and precision motion control and optimization technologies.

Scott Jordan is head of photonics for PI and a PI fellow. A physicist with an MBA in finance/new ventures, Jordan has made multiple contributions to photonics alignment automation and precision motion control and optimization technologies.

Matt Price is a technical manager for PI, working in precision automation technologies for microfabrication and metrology. A physicist with a background in laser materials processing and characterization, he has contributed to the development of motion technologies to advance capability in these fields.

Matt Price is a technical manager for PI, working in precision automation technologies for microfabrication and metrology. A physicist with a background in laser materials processing and characterization, he has contributed to the development of motion technologies to advance capability in these fields.

About PI (Physik Instrumente):

PI (Physik Instrumente) designs and manufactures high-performance motion systems at locations in the U.S., Europe, and Asia. Industries and fields of application include silicon photonics wafer test, fiber alignment, laser processing, astronomy/aerospace, medical engineering, and big science projects. With 50 years of experience developing standard and custom products based on piezoceramic and electromagnetic drives and more than 1300 employees in 13 countries, PI can quickly provide solutions for any positioning and automation project that requires high-precision motion control.