The need for modern technologies to dismantle existing underwater infrastructure is growing due to increasing demand for renewable energy sources. For example, to bring a wind power plant in the sea up to higher powers, the existing old steel frames, which may be below sea level, must first be dismantled so that engineers can rebuild them to obtain these higher powers.

In laboratory tests, researchers at the Fraunhofer Institute for Material and Beam Technology IWS (Fraunhofer IWS) have developed a shortwave green laser method for beneath-sea cutting that offers multiple advantages over commonly used techniques that use saws, automatic saw wires, and plasma cutters, for example.

According to the researchers, the technique is possible because of the availability of shortwave green lasers in the more-than-1-Kw-class, which are required to achieve the necessary cutting power. In the future, the researchers said, shorter-wavelength versions with blue lasers are conceivable.

At the same time that the existing green lasers are operating in water, the researchers said, the water serves to expel the resulting melt from the kerf with pressure. This eliminates performance disadvantages such as power losses and the need for extra gas lines. Although cutting metal with lasers is not a fundamentally new approach, the Fraunhofer researchers said that this is usually done in a dry environment using infrared or other longwave laser radiation. Coaxially with the beam, auxiliary gases remove the molten metal in the process.

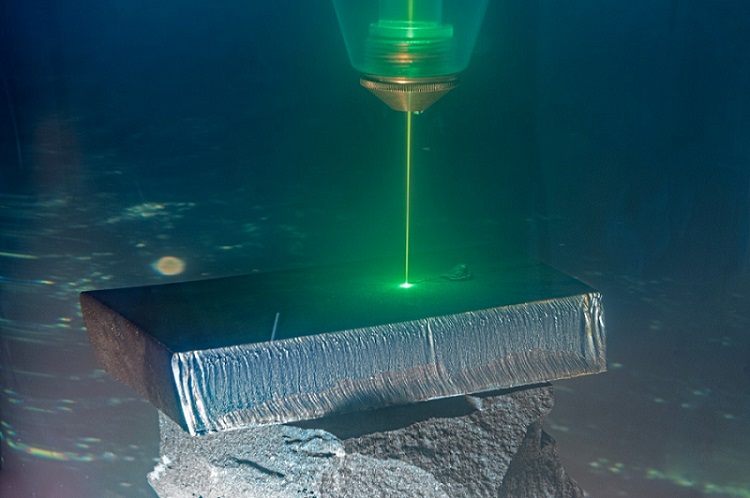

A shortwave green laser cuts steel in undersea conditions. Fraunhofer IWS researchers developed a laser-based method for beneath-sea cutting that they believe offers multiple advantages over commonly used techniques. Courtesy of Fraunhofer IWS.

In the sea, however, water scatters longwave light in all directions. As a result, a large part of the laser power dissipates after a short distance. Complex piping systems are also required for the auxiliary gas.

Using lasers with much shorter wavelengths than most industrial lasers penetrate water without significant losses; as a result, these lasers can also be used in bodies of water. This medium, which is abundantly available in the sea, can replace the cutting gas required in a dry environment, which in turn eliminates the need for gas pipelines.

Further, gases and gas mixtures such as air can be compressed to a certain point before they are used in the actual application. Water, on the other hand, can hardly be compressed. Therefore, as a cutting medium, the technique removes the melt residue at the interface with less force and loss of time.

Project leader Patrick Herwig, head of the laser cutting group at Fraunhofer IWS, said that the approach also enables the construction of compact underwater robots with laser attachments. Because designers could implement these mechanisms to be smaller and more efficient than the automatic sawing machines of today, the attachments could operate in difficult-to-access areas of underwater structures.

Also, unlike sawing, for example, dismantling teams would not need to continuously load future cutting lasers with new blades or other supplies. In addition, such a system does not generate waste or release hazardous materials into the atmosphere. The Fraunhofer researchers said that this particular advantage is important when demolishing old nuclear power plants. In these instances, steel components often have to be dismantled underwater before new building can take place. If cutting gas were used, radioactive waste could reach the water surface with the bubbles.

The researchers next want to further develop the lab-scale proven concept into practically applicable systems. Fraunhofer IWS said it will present the process at the SCHWEISSEN & SCHNEIDEN trade show this week to advance the method to application maturity together with industrial partners.