Every even year, the industrial laser community meets in the medieval city of Aachen, Germany, for the International Laser Technology Congress AKL. The three-day event convened 525 participants and 81 speakers from 21 countries this year for the congress’ 14th iteration. The event is organized by the Fraunhofer Institute for Laser Technology ILT (Fraunhofer ILT), which hosts one of Europe’s largest research and application labs. The event includes the Innovation Award Laser Technology presentation and ceremony as well as an open house event on the Aachen premises.

What is so special about AKL? Attendees will witness people from industry and applied research discuss their work in exceptional detail. For example, digitalization has been discussed for decades — many of the talks covering the topic at conferences and symposia shared informative slide decks — but during AKL ’24, two subsequent talks presented real details from the digitalization project that automotive titan Mercedes Benz has undertaken with laser machine producer TRUMPF. The insights ranged from contracts for automation data (for example, on who owns which data, and, what happens to processed data) to figures on how far TRUMPF increased availability in production at Mercedes Benz. Both teams are continuing to use their experiences to blueprint similar projects in digitalization.

Constantin Haefner, director of the Fraunhofer ILT and Professor at nearby RWTH Aachen university. Courtesy of Fraunhofer ILT,

Aachen, Germany.

To further explain the significance of digitalization, it describes the application of digital technologies to industrial processes, and has been a hot topic and pursuit in this industry for decades. Currently, digitalization starts with a digital twin — a piece of software and data that describes a machine, a part in processing, or even a manufacturing process. With the use of a digital twin for every part in a company’s production, users or designers can build and test a factory on a computer. Then, when the factory is built, every part can be traced while it is being processed.

Digitalization also enables users to learn about their machines from their real data. TRUMPF’s specialization in this area is in predictive maintenance, that is, a software tool that predicts machine failure in advance. In the Mercedes project, the TRUMPF team observed thousands of systems and predicted >90% of all maintenance cases, related to just 300 lasers, over the course of one year.

These were only two of the impressive presentations on relevant topics, and of course, one can speak with the experts on this initiative, or any other; the atmosphere in Aachen is professional but equally informal. Many former students, experts from Fraunhofer ILT, and the nearby RWTH Aachen University have moved to industry. At AKL, they all reconvene. Although AKL is a sort of family meeting, the event embraces those from outside ILT, as I can personally attest.

What (else) was remarkable?

I have written reports on AKL congresses for eight years now. I have seen big topics arise over the years, with some to subsequently vanish. This year, one big trend was not totally visible — namely, the laser has become a commodity, at least in the case of fiber and direct diode laser systems.

This, of course, has many consequences. Bo Gu, founder and president of BOS Photonics, reported on a market cleanup for these systems in China. The commoditization of these laser systems also enables many new large-scale applications, such as laser cleaning and laser heating.

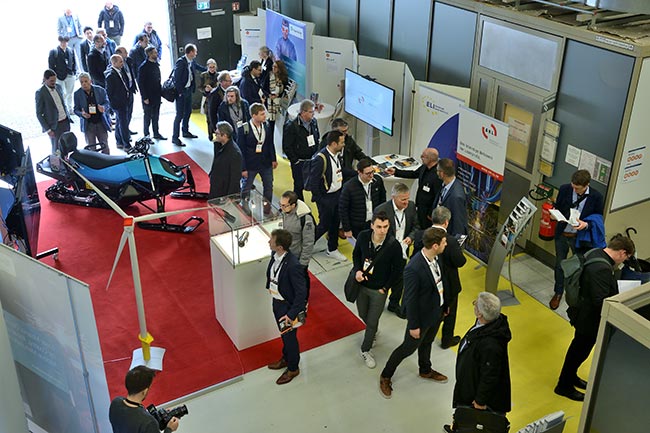

A unique chance for meeting an expert is the open house event at Fraunhofer ILT with about 60 labs open for visit. Courtesy of Fraunhofer ILT, Aachen, Germany.

Further, many specialized laser systems are still apt to undergo further technical developments. In silicon annealing for display production, where large excimer lasers have been used for 20 years to convert amorphous silicon into polycrystalline silicon, a transition is underway — from excimer to solid-state lasers. This may shake up a market in which a dominant excimer laser manufacturer is now poised to face competition from established solid-state laser developers.

Finally, blue diodes, with 5 kW per system, are emerging, as are ever-stronger ultrashort-pulse lasers and a number of special wavelength lasers. After all, for each process there is a proper laser today. This leads to one more important conclusion from the commodity trend: If laser vendors are striving to excel, then they need more than a laser. They need process know-how, special optics, reliability, and, maybe, new tools such as digitalized machines and production lines.

In the pipeline?

The AKL’24 program highlights state-of-the-art technology in additive manufacturing, cutting and welding, and surface technology, to name only a few application areas. The program also spanned topics that are more future-looking, and that have much less maturity.

Quantum technology, for example, was a big topic this year. Two teams, from the Delft, Netherlands-based research institute QuTech and New York-based Qunnect Inc. arrived in Aachen and presented “real” quantum networks — networks in which entanglement is established and shared between three distant nodes. They assume a quantum storage device, which the teams used for the first time in multicity networks. The technology is impressive, though network operators, such as Deutsche Telekom, which owns a majority of T-Mobile, are still hesitant when it comes to progress. “We're not there,” said Marc Geitz, head of Deutsche Telekom’s T-Labs research unit.

And there is a new topic even beyond quantum: laser or inertial fusion. After decades of research, successful experiments highlighted by the 2022 advancement at the National Ignition Facility (NIF) have captivated the realms of science and beyond in recent years. Many additional facilities and teams have contributed to this scientific success, although it was NIF that made it to the evening news. One may ask how this feat can be built upon.

Two presentations broached this question with bold statements of their own. The first, from Peter Leibinger, chairman of the supervisory board of the TRUMPF group, was mentioned during the keynote lecture at the presentation of this year’s Innovation Award Laser Technology. Leibinger, who is an expert in the field of innovation management, shared his thoughts about the culture of innovation. He referred to an almost impossible machine — ASML’s extreme-ultraviolet lithography machine. AMSL developed the machine in a high-tech ecosystem. In the end, though, only a few key managers believed in the idea and made decisions that drove the development.

Innovation Award for Laser Technology third place winners from Cailabs along with representatives of AKL. Courtesy of Arbeitskreis Lasertechnik eV/Andreas Steindl.

Would such an accomplishment be possible for quantum technologies and laser fusion, too? Yes, but huge challenges lie ahead. Advancements in these areas require orchestrated efforts from all partners. Road maps must be established. And access to venture capital must be supplied. “In the end, it comes down to the people,” Leibinger said.

Two days later, the director of Fraunhofer ILT, Constantin Haefner, went a few steps further in his conference-concluding remarks. Haefner formerly headed the laser division at Lawrence Livermore National Laboratory (LLNL) before he moved to Aachen. He is currently closely involved with German initiatives for laser fusion research programs.

Haefner put numbers on the wall: a fusion power plant should not make one shot per day, but 15 per second. It would need a new laser architecture based on laser diode arrays with at least 15% wall plug-to-laser efficiency. Haefner envisions a laser beamline unit that is 50× stronger than LLNL’s High-Repetition-Rate Advanced Petawatt Laser System. And for the power station, 400 such units would be required, Haefner said.

That is not a vague vision, rather, this is the starting point for coordinated actions such as those to which Leibinger referred. A first funding program for the development of optical components for fusion systems, for example, recently garnered €18 million ($19.2 million).

The next call for laser development will follow in due course. Haefner assumes that it will take three years to develop a prototype for a beamline, and 10 years to turn it into a real workhorse that can be produced in large quantities. If such a power plant were to cost €10 billion, then ~40% would be spent on lasers and optics. This would be a game changer in the laser and photonics market.

Today, Europe and Germany are well positioned to compete in this field, with the U.S. being the leader and China wanting to bring a fusion power plant online in 2050.

It was all a furious finish. AKL’26 will reveal how much has been realized.

[email protected]