A somewhat overlooked part of the electromagnetic spectrum, terahertz could transform the way manufacturers measure material thickness for paints, coatings, papers, and thin films.

MARIE FREEBODY, CONTRIBUTING EDITOR

Contact-free thickness measurements are increasingly important in industrial process monitoring and quality control. In the automotive and aviation industries, the exact thickness of paint and coating layers not only affects the overall appearance but also the level of protection against UV radiation and corrosion. In pharmaceuticals, the coating thickness governs the release of the drug within the human body, affecting a drug’s efficacy and potential side effects. Within the semiconductor industry, highly homogeneous polymer coatings protect against moisture and dust and function as stress absorbers.

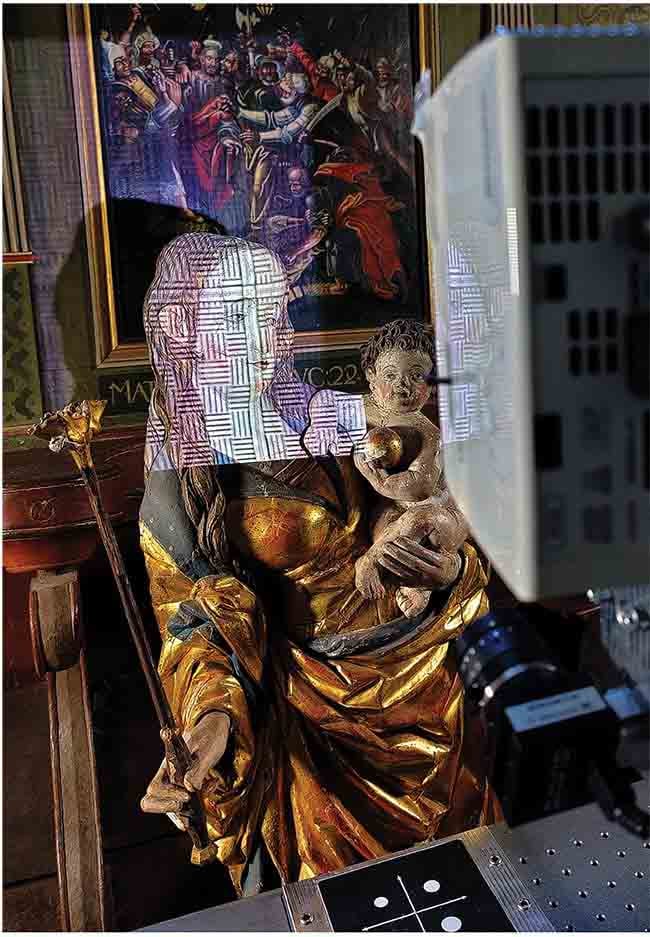

Wooden sculptures, such as the Mary figure in the Isenhagen Monastery, were scanned before and after restoration by researchers at the Philipps University Marburg and the University of Applied Sciences and Arts Hildesheim/Holzminden/Göttingen, in the course of a collaborative project with Menlo Systems. Courtesy of Menlo Systems.

To date, the electromagnetic spectrum has proved to be an invaluable resource. Yet, one segment of this spectrum has remained largely untapped until recently — the terahertz region. Spanning from ~0.1 to 10 THz, the region sits between microwave and infrared radiation.

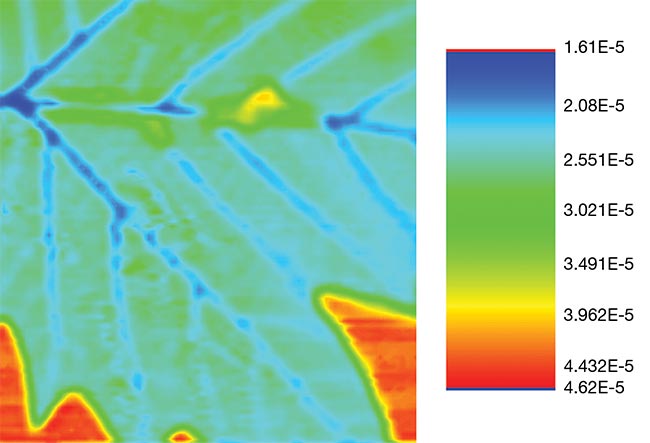

Mapping the water content in plants by terahertz imaging. Courtesy of Menlo Systems.

“Some people refer to terahertz technology as the ‘new frontier,’ which is not far from reality,” said Faezeh Zarrinkhat, application scientist at TeraView Ltd., U.K. “Terahertz has been overlooked until recent decades, mainly due to technical challenges in the generation and detection of terahertz waves.”

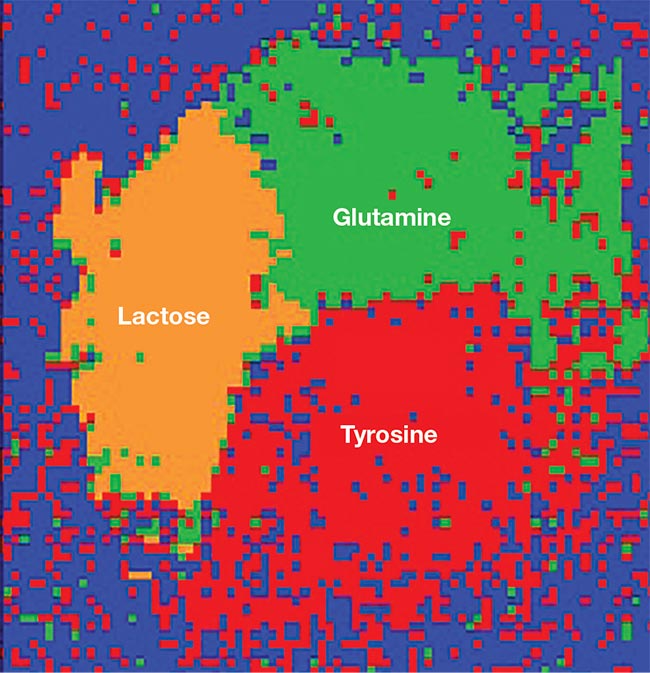

The cluster map of biomolecules has been generated from terahertz imaging of a sample comprising three substances, after data processing using Menlo Systems’ ImageLabHyperpectral Imaging software. Mapping regions of different biomolecular substances is particularly useful for assessing pharmaceutical products.

Courtesy of Menlo Systems.

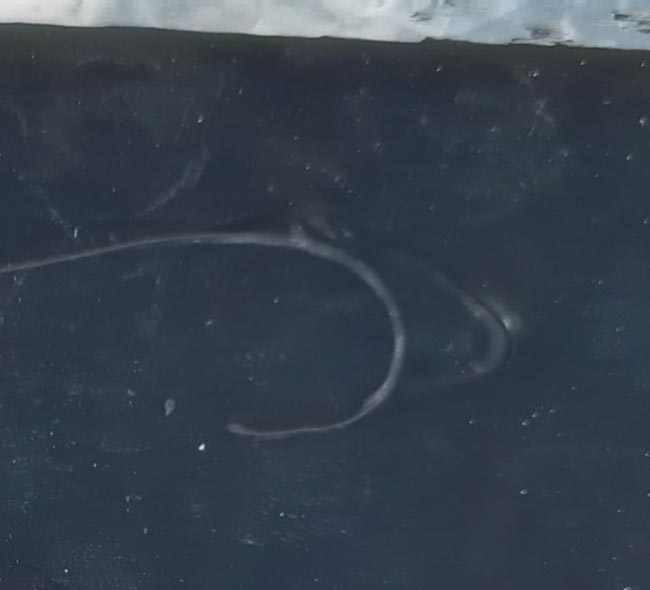

A measurement of the internal ethylene-vinyl alcohol copolymer (EVOH) oxygen barrier is crucial for this extruded plastic product to prevent spoilage in thermoformed containers. Online process control with a Luna terahertz sensor generates cost savings by shortening startup time and minimizing EVOH usage. Courtesy of Luna Innovations.

Today’s commercially available terahertz systems feature advancements compared to previous generations, capable of generating greater output power and bandwidth in a more compact footprint. These attributes, coupled with lower costs, are attracting increasing interest for material thickness measurement, particularly for paints, coatings, papers, plastics, and thin films.

Characteristics of terahertz pulses

The major value of the terahertz region is that the wavelength is short enough to provide adequate spatial resolution, while it is long enough to penetrate through most nonconductive but optically opaque materials.

Das-Nano, leading innovator in industrial coating inspection, uses terahertz radiation in its patented technology for automated surface characterization. The method greatly improves the quality and efficiency of coating processes. Courtesy of das-Nano.

This includes semiconductors, polymers, and ceramics, making terahertz radiation a versatile tool for measuring the thickness of single and multilayer surfaces in industries ranging from automotive and aerospace to roofing insulation and pipe extrusion.

Terahertz gives engineers a nondestructive way to gauge thickness of individual layers, as long as adjacent coatings differ in refractive index. Unlike most traditional thickness gauges, terahertz requires no physical contact with the layer under test, which uniquely enables in-process monitoring such as drying or curing of wet coatings.

“Work in the terahertz region of the spectrum has moved from astronomy to the laboratory, and now to industry. This evolution has taken over 20 years but is now being actively deployed in an ever-expanding number of market applications,” said Irl Duling, director of business development at Luna Innovations Inc.

While market acceptance has taken years, companies such as Luna Innovations now have hundreds of systems in manufacturing operations around the world, most used for real-time process control of the production line.

“Our systems can generate terahertz waveforms in industrial conditions at up to 1000 Hz, and a single waveform might include up to eight or more independent measurements,” Duling said.

These capabilities have made it a go-to technique for measuring aerospace coatings, battery coatings (primarily cathode), building products, such as roofing materials and foam insulation, and medical tubing. Terahertz systems can also monitor the application of adhesives to various substrates, and extruded plastic pipe.

As systems become more robust, less expensive, and easier to build, a number of new markets are expected to open for applications where beta gauges are traditionally used, such as the tire and rubber market and coated steel pipe. The choice between transmission, reflection, or a combination of both methods is highly influenced by the substrate used. For measuring paint layers on metal or assessing defects in integrated chips, for example, reflection is the preferred method. This is because the metal completely reflects the entire terahertz signal.

A diagram of the TeraLyzer pro reflection scheme depicts terahertz thickness measurement of coatings on a metallic substrate. Courtesy of Menlo Systems.

“For direct measurements of thicknesses, time-of-flight measurements of the sample are compared with that of a reference,” said Prince Bawuah, product manager of terahertz systems and synchronization at Menlo Systems. “In transmission setups, the reference is typically air, while in reflection measurements, the reference is taken from a metallic mirror.”

Transmission is the preferred approach to evaluate volumetric properties, such as porosity, or to identify potential internal defects. The penetrative, nonionizing property of terahertz is increasingly relevant for assessing pharmaceutical products, foam objects, and even historical artifacts.

Automotive paints

In the automotive industry, where the aesthetic appeal and protective functionality of a vehicle is paramount, achieving consistent and precise paint thickness is crucial. Terahertz radiation excels in measuring paint thickness nondestructively, giving automotive manufacturers a powerful tool to ensure uniformity and quality in their products, which improves aesthetics and durability while reducing production costs and material waste.

The Spanish company das-Nano has developed a system that includes a

laser module from Menlo Systems that provides the optical pulse necessary to generate the terahertz waves with the

required quality to assess paint thickness. The company’s measurements take less than a second and are accurate up to

1 µm, allowing thicknesses of every layer in a multilayer system to be obtained simultaneously.

The company cites material savings of 5% due to thickness optimization, reduction of reworks of 3%, and a reduction in environmental impact, along with improved homogeneity and appearance.

The auto industry has increasingly incorporated new materials that are structurally stable and lightweight. Such composite plastics are of particular importance in structures, such as bumpers, that are expected to return to their original form after minor crashes and are often painted to look identical to the rest of the car’s body.

Unlike metal-based parts, measuring paint on a plastic substrate can use either reflection or transmission approaches, or both can be used simultaneously. While well-established methods based on eddy current or photothermic principles often fail for composites due to the absence of a metallic substrate, terahertz technology can overcome this substrate dependence. Such fiber-reinforced composite materials are made of multiple layers of glass or natural fibers. As long as the layers have sufficiently different refractive indices, then terahertz can isolate and resolve each one.

Terahertz in the arts

In addition to directly measuring paint layers, terahertz provides spectroscopic data such as phonons, polaritons, and chemical molecular resonances. Resonance data is valuable for art conservation, as it can authenticate the originality of a work through the identification of chemical components within the paint.

Depth-profiling of historical wooden art objects reveals defects, such as paint delamination and cavities, caused by pest infestation or mildew. The analysis helps to classify the type and degree of damage and inform the ideal restoration treatment plan of the objects.

Menlo Systems teamed up with researchers at the Philipps University Marburg and the University of Applied Sciences and Arts Hildesheim/Holzminden/Göttingen to develop a terahertz-profiling system for art conservation inspection. The collaboration resulted in a robot-assisted terahertz device capable of creating a 3D map of the interior structure of delicate objects. The system emits terahertz pulses that penetrate the object. If the pulse is reflected at a transition from material to air, then there is a cavity. Scanning and compiling the data enables cavities — either within the object or due to delamination of paint layers — to be modeled.

“A resolution of around 1 mm in three dimensions was achieved, which is roughly the terahertz wavelength and the typical resolution obtained in far-field terahertz applications,” Bawuah said.

Battery electrode inspection

The global battery industry has grown rapidly, driven by demand for lithium-ion batteries to power electronic devices, hybrid vehicles, and electric cars. Efficient electrode production is paramount in battery electrode inspection.

“Terahertz technology is revolutionizing battery electrode inspection, offering a cutting-edge solution to a crucial aspect of the battery manufacturing industry,” said TeraView’s Zarrinkhat. “Approximately 22% percent of the cost of battery production is dedicated to the electrode production line.”

Currently, ~4% to 5% of materials are typically wasted due to manufacturing errors on the battery production line. Terahertz technology addresses this challenge by providing remote sensing capabilities for key performance indicators such as coating density, thickness, and conductivity.

“Terahertz sensors, capable of measuring all these parameters simultaneously

in real time, facilitate precise adjustments in the production process, ensuring a reliable supply chain to meet the global demand for high-quality batteries,”

Zarrinkhat said.

To address the effect of harsh and changeable industrial environments,

TeraView Ltd. developed a self-referencing terahertz sensor that is equipped with an additional internal mirror that provides a unique reference for each measurement, tracking any changes. This information is later used to correct the sample signal. The method can be conveniently accessed by users through software associated with the sensor.

While Zarrinkhat said it is too early to provide an accurate estimate of savings, defects during manufacturing, such as flaws in the calendering and material impurities, can be revealed remotely.

Time-domain terahertz

Time-domain terahertz is a technique that uses ultrashort laser pulses to generate terahertz pulses that are then sampled in the time domain using delayed laser pulses and a detector, which is only active for a subpicosecond time window.

By varying the delay between the laser pulses, the terahertz waveform is sampled, providing phase-sensitive measurements. Today’s industrial time-domain terahertz systems provide dynamic ranges of >60 dB and a frequency range from <100 GHz to >4 THz in a measurement time of 1 s.

An image of a battery cathode captured with an optical-range imaging sensor (top) and a terahertz sensor (bottom). Though the optical imager reveals some defects, terahertz imaging provides highly valuable finer details of the electrode’s flawed calendering. Courtesy of TeraView Ltd.

At Luna Innovations, a 1064-nm pulse is generated by a mode-locked fiber laser and directed over an optical fiber to a small antenna, which is fabricated on a specially grown semiconductor material. Acceleration of the generated carriers, due to a direct current bias across a gap in the antenna, creates a single-cycle pulse of terahertz energy.

“This short pulse is bounced off of the object to be measured,” Duling said. “For a single layer, there will be a reflection of the pulse from the front surface and from the rear surface of the layer. By measuring the time delay between these two pulses, and knowing the speed of light in the material, we can measure the thickness.”

These systems can characterize submillimeter layers down to −10-μm absolute thickness. Evaluating subwavelength thickness layers relies on powerful retrieval algorithms that must be sophisticated enough to make complicated measurements, but easy enough to use that a nontechnical person can run it.

“Great progress has been made in terahertz electronics, sources, and detectors, to the point where current performance is mostly limited by the readout electronics themselves, by factors such as bit depth and amplifier noise,” said Bawuah.

In the future, terahertz techniques could be integrated with other well-established microscopy methods to push spatial resolution even further. For example, attocube systems AG recently demonstrated its THz-neaSCOPE+s for terahertz imaging and spectroscopy at the nanoscale with spatial resolution of ~20 nm across the whole terahertz range.

The system combines scattering-type scanning near-field optical microscopy probing principles with a time-domain spectroscopy system to reach the spatial resolutions of an atomic force microscope. This enables nanoscale profiling of free-carrier density in semiconductors and vibrational nanoscopy in nanostructured samples.

Aside from fundamental research, the turnkey system is an efficient tool to characterize electron motion in nanostructure surfaces such as semiconductors. Using dual-beam parabolic mirrors to separate illumination and collection channels instead of beamsplitters or isolators, the system reduces transmission losses and collects more of the nanoscale terahertz signal.

While Luna Innovations currently manufactures its own transmitter (coherent source) and receiver (detector), Duling said that higher efficiency terahertz sources and higher sensitivity detectors would provide higher signal-to-noise ratios.

“It would allow investigation of thicker high loss materials, or would allow faster measurements with higher precision,” Duling said. “As an example, the standard industrial sensor of Luna Innovations produces 2 THz of bandwidth in 1 ms and can measure thicknesses down to 30 µm, while the enhanced performance sensor, which can produce 2 THz of bandwidth in 1 ms, can measure down to 15 µm.”

“One of the fundamental characteristics of the product that will influence system design is the minimum thickness,” Duling said. “Since the pulse we generate has a width dictated by the bandwidth, the thinner the product, the narrower the pulse required to measure its thickness.”

So, for a relatively thick coating, a

collinear optical path for the terahertz beam might be used, while for a thinner

coating, a ‘pitch-catch’ arrangement would provide higher bandwidth and allow for a shorter terahertz pulse.

“Shorter, cleaner optical pulses from the mode-locked laser would provide higher bandwidth, while lower loss fiber components (splitters, combiners, etc.) would allow for less optical amplification to compensate their loss,” Duling said. “Our current laser produces between

100 and 110 fs. A laser that could produce a pulse of 80 fs or less, at the transmitter,

would allow even thinner layers to be measured.”

Cost barrier

Since the first terahertz system was devised, cost has been the biggest factor in preventing its spread from laboratory to the production line. Given the main driving cost of a terahertz time-domain spectroscopy system is the ultrafast laser, efforts are underway to replace costly femtosecond sources with multimode diode lasers, such as superluminescent diodes. Chip-based lasers and components would mean that terahertz technology could truly go miniature and become more readily available for customer applications, potentially at a much lower price.

Current diode lasers do not perform as well as a standard time-domain spectros-

copy system but could be sufficient for applications with moderate demands. According to Joachim Jonuscheit, deputy head and development manager of

Materials Characterization and Testing

at Fraunhofer ITWM, moderate demand applications are those in which the thickness to be measured is ~100 µm and thicker.

“The costs of a sensor based on superluminescent diodes can be in the range of €10 or less,” he said. “This could be a reality in five years.”