A spectroscopy technique has enabled the study of nanolevel imperfections in the surface of glass. The process could lead to improvements in glass products such as electronic displays and vehicle windshields, according to a team of international researchers that aims to produce a technique capable of detecting the kind of structure change that takes place around nanolevel indentations on the surface of glass. Such an approach would shed light on the properties that determine the strength of glass.

One of the main focuses of Penn State professor of chemical engineering Seong Kim’s group is the study of glass surfaces, particularly their structure and durability in terms of their mechanical and chemical properties. Vibrational spectroscopy, also known as infrared spectroscopy, can be used to detect surface defects to a degree. However, if the type of defect generated on the glass surface is smaller than 10 µm, the defect cannot be properly analyzed or imaged using the technique. Raman spectroscopy, which is often favored in the research and study of glass, offers better spatial resolution, though it is not sufficient for structural analysis at the nanoscale.

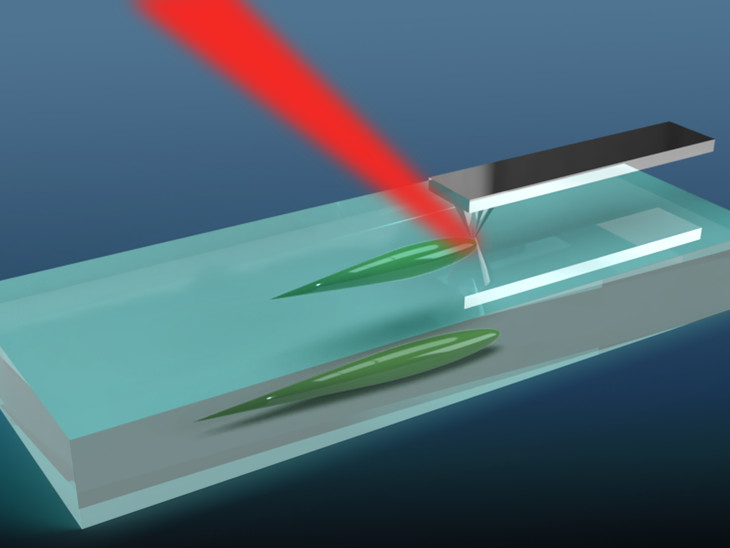

With hyperspectral near-field optical mapping, an infrared light beam can reveal nanolevel imperfections and damage that weakens the glass sample. Courtesy of Elizabeth Flores-Gomez Murray, Penn State MRI.

In their research, Kim’s group used Corning Gorilla Glass, favored in smartphone displays and recently windshields and airplanes for its high level of durability. The glass that consumers are touching on their smartphones or that pilots are looking through is not as strong as it was when it first leaves the manufacturing plant, due to tiny scratches and other damage during physical contacts made by paper contact, vibration in a truck, sitting in packaging, and regular jostling during unloading. The defects may not be visible, but they are enough to weaken the glass.

To study imperfections at that scale, Kim turned to Slava Rotkin, a professor of engineering science and mechanics, who uses the instrumentation technique of hyperspectral near-field optical mapping in his work. The method uses a scattering scanning near-field optical microscope and offers both optical spectral resolution and high spatial resolution.

Kim’s team indented a glass surface with the tip of a tiny instrument to create nanolevel indentations a few hundred nanometers deep, and one or two microns wide. With Rotkin’s instrumentation technique, the team was able to visualize the effects on the glass resulting from the indentations, beyond even topographical damage.

The team noted the potential for imperfections as small as the ones they studied to influence data. A camera on Mars, for example, may measure spectral properties on the planet’s surface, though a scratch on the glass could affect optical properties, and by extension the mechanical and chemical properties necessary for accurate detection.

“By understanding nano surface damage over multicomponent glass materials using the technique like this, we can significantly increase our fundamental understanding of glass science,” Kim said.

The NSF supported the research, which was published in Acta Materialia (www.doi.org/10.1016/j.actamat.2021.116694).