Thermoelectric coolers are helping industrial laser sources to maintain their precision, power, and performance in increasingly complex manufacturing processes.

ANDREW DEREKA, LAIRD THERMAL SYSTEMS

The increasing demand in many end markets for advanced manufacturing systems that are able to increase production and cut costs have positioned laser systems as an important fabrication tool. High-powered lasers, such as CO2 sources, are used for coarse cutting of metals, while ultrafast lasers are employed for finer cutting and polishing of semiconductor materials. Fiber lasers have the versatility to perform both tasks.

Miniaturization of consumer electronics, the electrification of vehicles, and the expansion of green energy are all trends that are driving the need for advanced laser machining systems, as well as laser additive manufacturing, to create complex designs. These and other trends require the use of a combination of laser technologies, sometimes running in parallel to accomplish coarse cutting, welding, fine cutting, or polishing at high speeds.

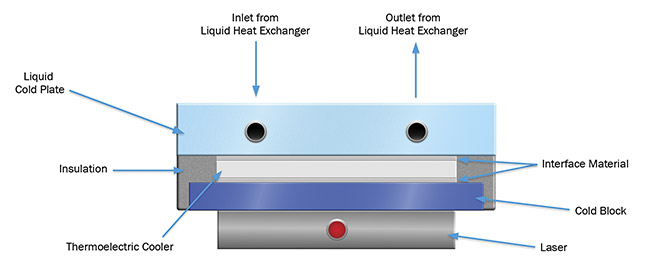

Thermoelectric coolers provide spot cooling for high-performance industrial lasers. Courtesy of Laird Thermal Systems.

High-power industrial lasers can generate outputs in excess of 10,000 W when processing thick metals, generating a significant amount of heat not only in the targeted surface but also in the sensitive optics inside the laser. The temperature

of these optics needs to be maintained

to achieve peak performance for the tool. If the optical material undergoes significant changes in temperature, it can cause inefficiencies that result in sputtering or poor welds. While compressor-based refrigeration systems have long been used

to cool such laser systems, thermoelectric-based coolers can offer superior spot cooling for low-power lasers and their optical components by providing energy-efficient and maintenance-free operation to lower the total cost of ownership.

Application overview

Laser systems are increasingly replacing the CNC machines used in fabrication — for processes such as cutting, welding,

drilling, and etching — where they offer industrial manufacturers ways to reduce costs while increasing throughput and quality. Although laser systems are comparatively more expensive than CNC machines, the ability of laser systems to speed cutting or welding times, fabricate

complex parts with unique pattern structures, and produce parts with a high number of redundancies often justifies the investment. Laser additive manufacturing

systems can also create complex parts that cannot be made with CNC machines.

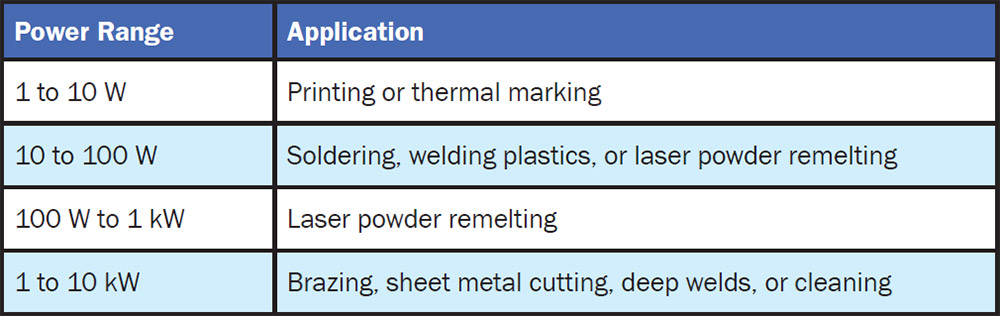

The selection process for an industrial laser is based on the beam diameter and the depth of cut that it can achieve in the material that the end user is processing. Each market application requires a specific laser power range, as illustrated in the table below.

Industrial lasers systems with output greater than 10 W typically require some kind of active cooling to maintain reliable system performance. Larger systems that emit more than 500 W often require an external compressor-based chiller, while smaller systems emitting less than 500 W

normally rely on thermoelectric-based chillers or thermoelectric coolers.

Internal optical components also require temperature control to ensure optimal laser performance. Depending on the material of the optics, they need to be kept within a nominal temperature range between 20 and 35 °C, with a temperature stability of ±0.5 °C.

This applies to the internal optics of

gas and solid-state lasers, but thermoelectric coolers are also installed inside the laser diodes used in fiber lasers to keep the temperature of the diode stable even

if ambient temperatures fluctuate.

Future applications will bring new challenges to laser design and fabrication. Examples include emerging applications in quantum technologies, the 3D printing of human organs, customized single-piece processing, and very large-scale processing operations. Such applications will often require more customized light control techniques that are able to tailor the laser’s output to optimize the energy deposition required for the task. New wavelengths will be required to improve process efficiencies, such as ultrashort high-power UV lasers and ultrashort far-infrared lasers. For high-volume production, multiple beam processing will be required. In all of these emerging applications, new recirculating chillers with optimized cooling capacities will also be required to adequately control heat and optimize performance of the laser.

Thermoelectric coolers can be mounted on top of a laser or inside the laser diodes. A thermal interface material should be used on either side of the module during assembly to maximize thermal conductivity. Courtesy of Laird Thermal Systems.

Power Ranges Required by Market Applications

As a laser beam’s energy passes through an optical lens, the residual heat can increase the temperature of the lens and distort the beam’s wavelength. Thermoelectric coolers are often used to manage this heat to prevent it from affecting the laser’s performance. The cooling capacity of a cooler needs to exceed the energy being absorbed by the lens plus parasitic heat losses caused by thermal shorting. The cooler then transfers the heat to a heat exchanger, where it is dissipated. This transfer can either occur through a direct conduction path or, for higher heat loads, a cold-plate heat exchanger. When the lens temperature is stable, the cooling power requirement is typically low.

Mounting challenges

Thermoelectric coolers can be mounted onto the side of the lens or onto the mounting fixture that holds the lens. To maximize thermal conduction away from the lens, a thermal interface material should be applied on either side of the module during assembly.

Standard thermal interface materials, such as greases, can outgas and contaminate the lens, which makes specially formulated thermal epoxies and phase-change materials with low outgassing characteristics more favorable. But to make sure outgassing is not an issue, these materials still need to be baked in an oven prior to installation.

An alternative mounting method

specifies thermoelectric coolers with metalized surfaces assembled with a low-temperature solder, such as indium tin (InSn), that melts at a temperature below the solder construction of the thermo-electric cooler. The challenge when soldering such assemblies is to minimize flux residue, as this can also outgas and contaminate the lens.

With no moving parts, solid-state thermoelectric coolers can significantly reduce operational noise, maintenance, and total cost of ownership, while offering high reliability. They also perform well in high-vibration applications. Courtesy of Laird Thermal Systems.

For lasers with footprints smaller than 100 × 100 mm, thermoelectric coolers are often mounted directly onto the exterior of the housing to provide temperature stabilization. Thermoelectric coolers for laser cooling often have a high heat-pumping density per square area to match the heat generated by the laser. Such devices can deliver heat flux densities up to 13 W/cm2. Thermoelectric coolers operating at these levels often exceed the ability of a heat sink and fan to dissipate heat into the surrounding environment. In such cases, an ambient liquid cooling system and cold plate is often a better option because its compact configuration can minimize space constraints while routing heat out to an area where there is more space to exhaust heat into the ambient environment.

One or more thermoelectric coolers within an array can be used to pump out comparatively higher heat loads. When using multiple arrays, it is important to lap surfaces of the cooler module, so that their thicknesses are within tight tolerances when mounting it to the heat exchanger. This ensures minimal air gap between the coolers and exchanger.

It is also important to protect laser electronics against condensation caused by the cooling process. The cold side of a thermoelectric cooler could reach 10 °C or lower to maintain a set point temperature of 20 °C. Such cold-side temperatures are almost certainly below the dew point temperature in most industrial settings, which will cause moisture in the air to condense. Sealing the perimeter of the thermoelectric cooler with epoxy or silicone is not sufficient to protect against this. So, it is recommended to add a second insulation barrier to protect the thermoelectric cooler cavity. All surfaces that go below dew point will require some type of insulation to keep moisture from condensing. This is usually a closed-cell foam or other type of insulation that does not absorb moisture and has good thermal insulating properties.

Thermoelectric coolers can also act as dehumidifier components in some laser systems. For high-power applications, large recirculating chillers are used to absorb heat generated by the laser and its power supplies that power the laser. In high relative humidity environments, however, it is possible for moisture to condense onto the cold-plate surfaces of these chillers, which can cause a field failure to the power supply. To minimize this risk, a thermoelectric cooler assembly can instead be used to lower the relative humidity inside the laser. The cold-side heat sink will condense the moisture in the air and route it away from the power supply and other optoelectronics inside the laser.

Ideal for spot cooling in industrial laser applications, thermoelectric coolers use advanced materials to enable higher heat-pumping capacities compared to standard semiconductor materials. Current thermoelectric coolers, from companies such as Laird Thermal Systems, also incorporate more effective thermal insulation barriers that can push temperature differentials up to 4 K higher than conventional thermoelectric cooler designs.

Cooler solutions

With the ability to cool surfaces well below ambient temperature and actively remove heat from sensitive electronics, thermoelectric coolers offer heat-pumping capacities of up to 300 W. This easily supports low-power laser requirements. Form factors for these coolers can range from 25 to 55 sq mm to better serve space-constrained laser designs. For the larger heat-pumping models, it is recommended to use a liquid heat exchanger on the hot side to optimize heat dissipation into the surrounding environment.

With no moving parts, solid-state thermoelectric coolers can significantly reduce operational noise, maintenance, and total cost of ownership, while offering high reliability. They also perform well in high-vibration applications.

Advancements in laser processing systems are enabling new products in consumer electronics, electrification of vehicles, and more efficient sources of green energy.

The complex manufacturing processes required to advance these applications rely themselves on sophisticated thermal management solutions to support heat removal and temperature stabilization of lasers and their optics.

The spot cooling that thermoelectric coolers provide to laser optics and power sources enables these sources to deliver more robust, low-power, and maintenance-free operation.

Meet the author

With almost 20 years of thermal experience, Andrew Dereka has served as Laird Thermal Systems’ thermoelectric product director since 2015. He earned a master’s degree in business administration from Rutgers University and a Bachelor of Science degree in mechanical engineering from the University of North Carolina at Charlotte; email: [email protected].