JENA, Germany, Aug. 3, 2022 — Two Fraunhofer institutes have delivered the core optical innovation supporting a recently launched space-based environmental mapping and analysis initiative. The components and devices supplied by the Fraunhofer Institute for Microengineering and Microsystems (Fraunhofer IMM) and the Fraunhofer Institute for Applied Optics and Precision Engineering (Fraunhofer IOF) comprise the enabling technologies of the Environmental Mapping Analysis Program — a German environmental satellite abbreviated as EnMAP.

The satellite launched from the U.S. Space Center at Cape Canaveral, Fla., April 1. The program is intended to span five years and deliver information on the effects of climate change, the availability and quality of water, and changes in land use.

The double-slit module during precision assembly in the coordinate measuring machine. The ultraprecise module designed by a team at Fraunhofer IMM incorporated two slits, positioned apart. Courtesy of Fraunhofer IMM/Tobias Hang.

A high-precision “double-slit” module that directs light into two detectors is a central element of the satellite’s spectrometric capabilities. Since the satellite detects light from the sun that is reflected by Earth to conduct analyses, and because light spanning from the visible band to deep infrared is too vast of a range to be recorded with only one spectrometer, the double-slit element is needed to direct incident light into two detectors.

The slits, which feature a graduated cross-section, are positioned slightly apart, meaning they are not focused on the same points of Earth. As a result of their positioning, it takes a fraction of a second for the second slit to “see” the same part of Earth as the first slit, said Stefan Schmitt, group manager at Fraunhofer IMM.

Identification of this offset with maximum precision enables recordings to be overlaid and to achieve the required resolution of 30 m.

According to the team at Fraunhofer IMM, the method used to manufacture the double slit module is only possible using silicon technology.

The researchers produced other module components — such as those used to deflect light or suppress scattered light — using materials suitable for space applications such as aluminum, stainless steel, nickel, and Invar.

A team at Fraunhofer IOF fabricated the satellite’s aluminum mirrors, which were required to feature a smooth surface and weigh as little as possible. The scientists deposited an x-ray amorphous metal alloy of nickel and phosphorus on the aluminum. The structure of this thick film showed similar properties to glass. It was also highly suited to machining with diamond tools and polishing to a high level of finish.

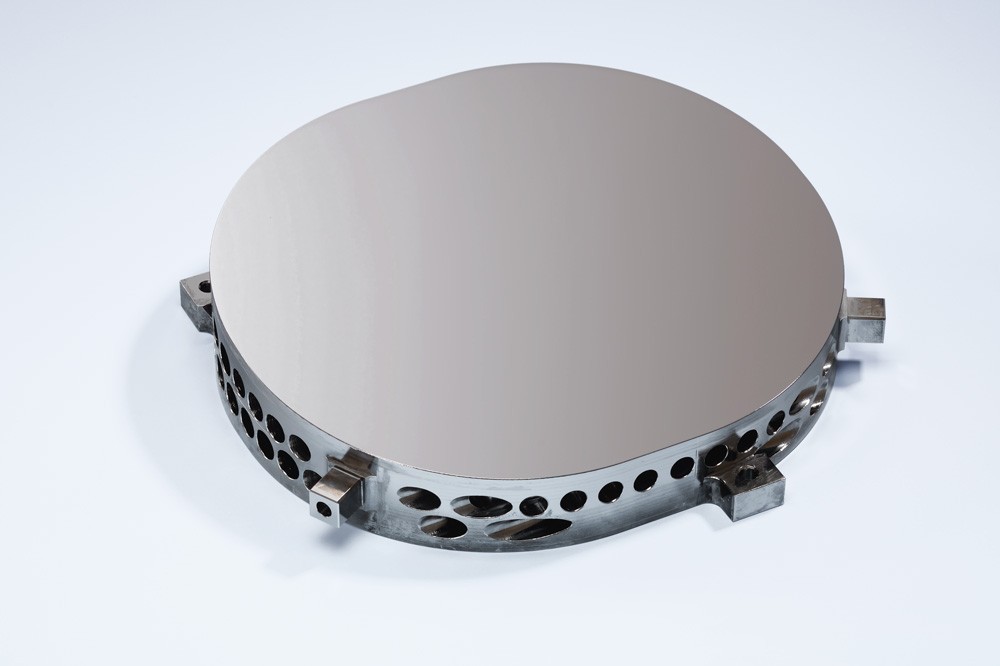

Metal mirrors designed by a team at Fraunhofer IOF demonstrated a roughness of less than 0.5-nm root mean squared (rms) when measured in white light — 50× magnification. The mirrors also retained shape deviation to meet project requirements of 18-nm rms. In some cases, the mirrors exceeded that metric. Courtesy of Fraunhofer IOF.

The researchers subjected the mirrors to corrective procedures such as ion beam figuring. The mirrors demonstrated a roughness of less than 0.5-nm root mean squared (rms) when measured in white light — 50× magnification. The mirrors also retained shape deviation to meet project requirements of 18-nm rms. In some cases, the mirrors exceeded that metric.

According to Stefan Risse, project manager at Fraunhofer IOF in Jena, the IOF team reduced the mass of the mirrors by more than 40%. It created a structure for the mirrors that featured cross bores meeting at right angles to connect the front and rear of each mirror, and a column structure to support the surfaces. The front and rear of each mirror were closed to give the element a high degree of mechanical stiffness.