Once a novel laboratory curiosity, quantum cascade lasers have matured enough to begin shaping a new frontier of applications.

TAYLOR STATHOPOULOS, DRS DAYLIGHT SOLUTIONS

Courtesy of DRS Daylight Solutions.

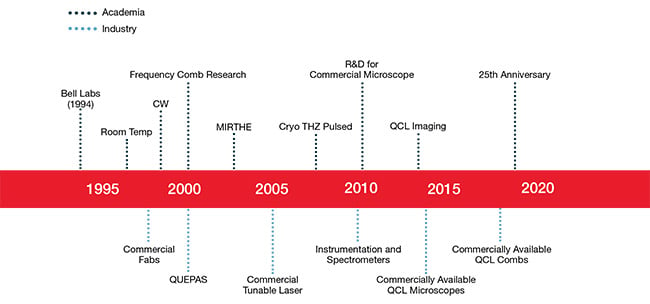

Since the unveiling of the quantum cascade laser (QCL) at Bell Labs in 1994, the technology has evolved — from being simply a

cutting-edge field in photonics research to being commercially available in the form of packaged lasers, QCL-powered scientific tools with control software, and robust integrated systems. These systems now support a wide range of applications in defense, materials analysis, environmental monitoring,

and medical and biopharma research (Figure 1).

Figure 1. A timeline of innovations in quantum cascade laser (QCL) technology. MIRTHE: Mid-Infrared Technologies for Health and the Environment; QUEPAS: quartz-enhanced photoacoustic spectroscopy. Courtesy of DRS Daylight Solutions.

QCLs have become a predominant source of coherent mid-infrared light, color center lasers, difference-frequency generation systems, optical parametric oscillators, and cryogenic lead-salt diode lasers in spectroscopic applications. They also find use in some higher-power applications where ruggedness and compactness are essential. As QCLs advance and applications accelerate, it may be helpful to revisit the basics underlying the technology.

QCL basics

Undergraduate physics students learn that the energy of an electron is quantized by the imposition of a confining electric potential. The quantized electron energy levels and energy-level differences increase as the spatial dimensions of the potential well become smaller. Electron transitions between levels may emit or absorb photons, subject to selection rules and conservation limits.

Distinctly different from semiconductor heterojunction diode lasers that involve recombination of conduction band electrons with valence band holes, QCLs instead exploit transitions between energetically confined states of electrons within the conduction band. In QCLs, quantum wells are formed in one dimension by alternating layers of semiconductor compounds with various bandgaps (e.g., GaInAs, AlInAs, or GaInAs). The layers are epitaxially grown on substrate wafers — typically InP — via molecular beam epitaxy, metal organic chemical vapor deposition, or both.

Quantum mechanical tunneling occurs between adjacent wells, with a probability that varies inversely with the height and width of the separating barrier. A series of multiple, thinly separated wells may thus be tunneling coupled, resulting in electron wave functions that span the length of the series. The expanded length of the effective confinement in such a region gives rise to closely spaced energy levels and increased motility of electrons. These injector regions transport electrons between the emitter stages.

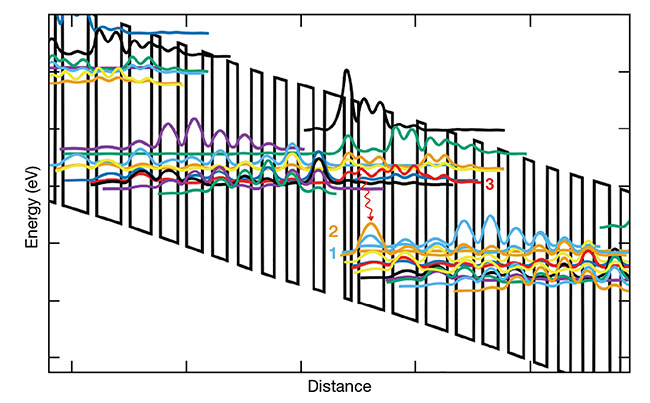

As seen in Figure 2, sufficiently applied voltage causes the injector regions to align closely in energy to, and quickly populate, the upper level (level 3) of the optical transition via resonant tunneling. After photon emission, electrons must be rapidly removed from the lower transition

level (level 2) or lasing will cease. To accomplish this, quantum wells and barriers in the emitter region are designed to create another energy level (level 1) that is lower than level 2 by the approximate energy level of an optical phonon. The resulting fast resonant scattering suffices to maintain population inversion between levels 3 and 2. A typical QCL comprises 10 to 100 concatenated injector/emitter layer sequences to provide a commensurate increase of optical gain for a given electrical current — albeit at the cost of a proportionally increased voltage requirement.

Figure 2. A conduction band energy diagram of a typical quantum cascade structure. Within the 100-nm span represented by the x-axis are alternating quantum wells and barriers and square moduli of wave functions at discrete energy levels. The optical transition of electrons from level 3 to level 2 is followed by phonon-enhanced nonradiative scattering to level 1 that, in turn, couples to a miniband of levels in the injector region. This combination rapidly depopulates the lower laser level 2 and transports electrons into the next active region. The sequence of active and injector regions composes one stage that is repeated in a cascade to allow emission of multiple photons for each electron passing through the structure. Design flexibility derives from specific material composition, lattice strain, thicknesses of barriers and wells, and doping. Courtesy of DRS Daylight Solutions.

This brief description belies the rich theoretical detail and technical proficiency required to design and fabricate working QCLs. The potential design space for these devices is vast and defies systematic exploration. However, decades of design variations and optimization efforts have established impressive benchmarks in optical power, efficiency, and wavelength coverage. The seminal textbook by Jérôme Faist provides a comprehensive introduction to the field1.

In summary, the electron energy levels and associated wave functions that drive QCL operation are determined by the controllable parameters of epitaxial-layer thicknesses of semiconductor alloy pairs and applied overall bias. Tunneling and scattering rates between states are modified by the overlap integrals of the wave functions. Controlling these rates, by design, achieves the population inversion required for optical gain.

The key point is that the performance characteristics of QCLs — and, most particularly, their emission wavelengths — are not dependent on the heterojunction bandgap. Rather, they are determined by the sequence of layer thicknesses composing the active medium.

Figure 2 illustrates this. The energy versus distance diagram indicates the sequence of quantum well widths associated with the layers in an applied bias. Quantum wells giving rise to optical transitions between laser levels 3 and 2 are separated by a sequence of narrowly separated wells comprising injector regions that quickly sweep electrons out of the lowest laser state, level 1, and into the upper level of the next active region. The nonradiative scattering of electrons from level 2 to level 1 can be enhanced by engineering the energy difference between the two levels to be in resonance with an optical phonon of the lattice.

To form functioning lasers, substrate wafers with the epitaxially grown layers are lithographically processed and etched to form rib or ridge waveguides. Optionally, semi-insulating material may be regrown on the sidewalls to enable epi-down mounting for improved heat extraction.

Wafers are diced and cleaved into individual Fabry-Pérot lasers that are mountable to suitable heat sinks. Although the Fresnel reflectivity and parallelism of the cleaved facets is sufficient to support lasing, the two facets may optionally be coated to different degrees of reflectivity to extract most of the optical power from one facet. Such lasers may be relatively high in output power, optical quality

(i.e., single spatial mode), and efficiency but exhibit broadband emission, lasing simultaneously in multiple longitudinal modes.

Epi-up devices may be further processed to form an index grating above the waveguide. This results in a single-longitudinal-mode emission that may be thermally tuned over a restricted range. To simultaneously realize high-power, single-mode operation and broad-range wavelength access, an antireflection coating can be applied to one facet of an epi-down Fabry-Pérot device before the device is optically coupled to an external cavity. The external cavity provides wavelength-selected feedback into the gain-chip waveguide either via a reflective diffraction grating or through the use of an external mirror and a transmissive intracavity wavelength-selection filter. Such external-cavity QCLs are rugged and compact and can be readily integrated into scientific instruments or application-specific equipment.

From experiment to solution

Shortly after QCLs were first demonstrated at Bell Labs, the technology was translated into commercial products. Early industry and academia alliances, such as the Mid-Infrared Technologies for Health and the Environment (MIRTHE) groups, pioneered the first early applications for QCL technology.

One of their early successes occurred during the 2008 Beijing Olympics, where a QCL open-path analytical system called the Quantum Cascade Laser Open-Path System (QCLOPS) measured ozone,

ammonia, and carbon dioxide in the

atmosphere. This early system showed that QCL-based systems could provide highly sensitive chemical information outside of a lab environment.

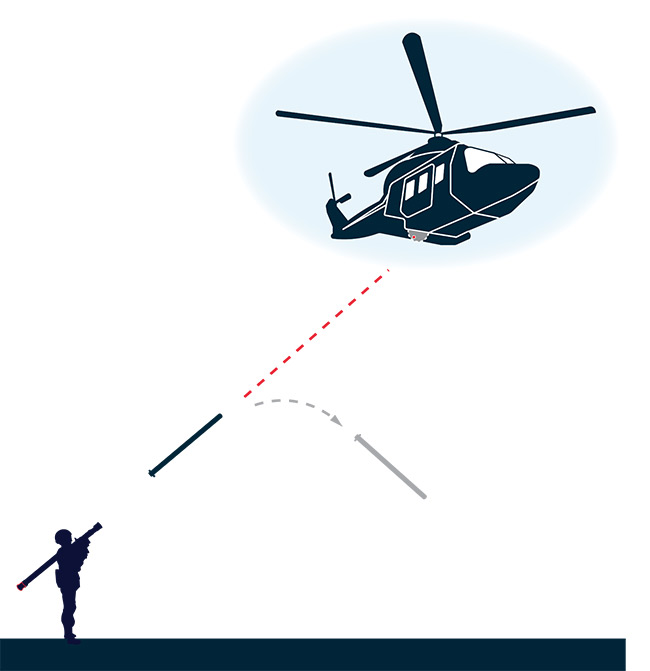

QCL sources have since continued to be trusted as essential components in reliable, high-precision scientific instruments, but they have also become ruggedized and miniaturized for commercial and military use. High-power QCLs are an ideal mobile defense solution because they are relatively compact and low-weight. This has prompted their application in directed infrared countermeasures (DIRCM), for example, which are systems mounted on rotary-wing aircraft to help counter heat-seeking shoulder-fired missiles. The designs of such aircraft impose strict limitations on the size and weight of the devices that can be fitted onto them (Figure 3).

Figure 3. Because they are rugged, compact, and lightweight, QCL-IR emitters are finding application as directed infrared countermeasure systems mounted on rotary-wing aircraft to help counter heat-seeking shoulder-fired missiles. Courtesy of DRS Daylight Solutions.

Researchers in the medical and life sciences sectors have also explored the potential of QCL-IR sources. Researchers at Goethe University in Frankfurt,

Germany, for example, have engineered early prototypes of a noninvasive glucometer that combines QCL-IR light with photothermal detection to spectroscopically probe glucose concentration in interstitial fluid residing in the layers of skin on a fingertip. The method has just undergone a promising preclinical validation2.

Similarly, QCL-IR sources hold great potential for high-sensitivity breath

analysis. Several researchers are employing the technology to explore biomarkers for disease within a breath sample. A patient could exhale into a gas cell, for example, and the rapid tuning of a QCL system could then detect whether chemical biomarkers are present in the breath. This application is in its early stages, but it is pioneering a future toward early disease intervention through practical and simple screening by health care professionals.

Additionally, as drug manufacturers move toward continuous manufacturing and Industry 4.0 best practices, they are voicing growing demand for robust analyzers that can characterize proteins — including higher-order structure information — and quantitate them continuously and in real time. QCL-based analyzers targeting this application have already entered the market and have seen broad adoption by the industry.

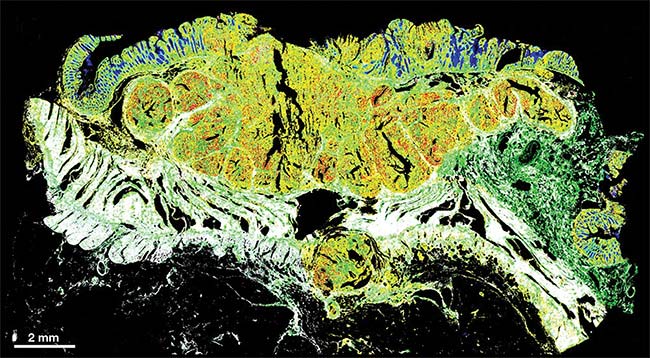

QCL technology is also enabling new approaches to microscopy. By coupling high spectral brightness of QCL sources with wide-field optics and a microbolometer detector, QCL-IR microscopy has enabled high-throughput capture of

hyperspectral images in under a minute for an astounding 2- × 2-mm field of view.

Researchers at Ruhr University

Bochum leveraged such microscopes to conduct a study comparing the effectiveness of QCL-IR microscopy to traditional histopathology, in which a series of immunohistochemistry labels were inspected under a light microscope.

The results from the study indicated that the infrared chemical imaging enabled by QCL-IR microscopy provided new spectroscopic biomarkers for early detection of cancer (Figure 4). The new markers demonstrated comparable sensitivity and selectivity to those gathered through traditional histopathology techniques3.

Figure 4. A chemical image of cancerous colorectal tissue constructed from hyperspectral data collected with a QCL-IR microscope. False coloring indicates a pathological region (red), inflammatory cells (yellow), muscle (white), connective tissue (green), crypts (cyan), and lumens (blue). Courtesy of Reference 3/CC BY 4.0.

Similar instrumentation is finding application in emerging microplastics analysis. Researchers at the Alfred Wegner Institute are using QCLs to build classifiers for microplastics samples to help combat the world’s growing plastic pollution crisis. The large field of view and hyperspectral imaging capabilities of QCL-IR instruments have accelerated data capture tenfold when compared to Raman and Fourier transform IR imaging4.

In both of the above applications,

QCL-IR imaging quickly offers spatial and chemical information about the sample of interest. This speed is particularly critical for analysis of a large volume of samples or when sample sets must be analyzed in a short period of time.

QCLs have also been integrated into spectrometer systems for gas and liquid phase analysis. The high-spectral brightness of these lasers enables direct transmission through a flow cell, avoiding the need to use attenuated total reflection to analyze a liquid or gas sample. This development is enabling in situ liquid analysis in a broad range of industrial applications, from characterization and quantitation of proteins in drug development to monitoring toxic ammonium levels in water treatment plants.

Professor Bernhard Lendl from the Vienna University of Technology is coupling tunable QCLs to high-performance liquid chromatography systems to measure the concentration of sugars in various beverages5. This flow-through liquid analysis shows great potential for real-time monitoring of solutions. In addition to benefiting the formulation of new drugs, it could also improve the quality control of our favorite soft drinks.

Yet another powerful application for QCL-IR is small in scale but large in impact. Nanoscale spectroscopic imaging is a relatively new technique that is able to capture hyperspectral images below the diffraction limit of light. The technique focuses a tunable infrared laser beam at the location where the probe tip of a scanning atomic force microscope contacts a sample. The probe-sample interaction is modified by the laser-sample interaction. While scanning the laser at a given location only reveals spectral information, scanning the probe tip also resolves the surface topology to produce images with chemical information that is spatially resolved to ~10 nm6. Several implementations of this spectroscopic technique have been developed to leverage the wavelength range of QCL light sources, and application of the technology could provide critical insights into our understanding of polymers, two-dimensional materials, and microelectronics.

Finally, QCL technology is opening up new opportunities in the terahertz-

frequency regime, particularly between 0.3 and 5 THz, where QCLs have demonstrated impressive performance characteristics when operating at cryogenic temperatures. Terahertz-range QCLs are offering new capabilities in applications such as the spectroscopic study of semiconductors, security and defense scanning, nondestructive testing, quality assurance, astronomy, biomedical imaging, and wireless communications.

Despite this broad and growing list of applications, QCL technology is still in the early stages of its commercial evolution, and much of its potential still lies ahead. Emerging component and system designs are introducing more compact, ruggedized sources with higher output powers and improved beam qualities. Meanwhile, researchers and engineers in dozens of fields continue to find innovative applications for these unique infrared and terahertz light sources.

Meet the author

Taylor Stathopoulos is sales and marketing manager at DRS Daylight Solutions, where she is responsible for managing and executing

integrated marketing communications strategies. She holds a Bachelor of Science degree in

marketing from San Diego State University and is currently pursuing a Master of Science degree in marketing at Johns Hopkins University; email: [email protected].

References

1. J. Faist (2013). Quantum Cascade Lasers. Oxford University Press.

2. T. Lubinski et al. (2021). Evaluation of a novel noninvasive blood glucose monitor based on mid-infrared quantum cascade

laser technology and photothermal detec-

tion. J Diabetes Sci Technol, Vol. 15,

No. 1, pp. 6-10, www.doi.org/10.1177/1932296820936634.

3. C. Kuepperet al. (2018). Quantum cascade laser-based infrared microscopy for label-free and automated cancer classification

in tissue sections. Sci Rep, Vol. 8, No. 7717, www.doi.org/10.1038/s41598-018-26098-w.

4. S. Primpke et al. (2020). Rapid identification and quantification of microplastics in the environment by quantum cascade laser-based hyperspectral infrared chemical imaging. Environ Sci Technol, Vol. 54,

No. 24, pp. 15893-15903.

5. T. Beskers et al. (2014). High performance liquid chromatography with mid-infrared detection based on a broadly tunable quantum cascade laser. Analyst, Vol. 139, No. 9, pp. 2057-2064, www.doi.org/10.1039/c3an01546g.

6. E.A. Muller et al. (2015). Infrared chemical nano-imaging: accessing structure, coupling and dynamics on molecular length scales.

J Phys Chem Lett, Vol. 6, No. 7, pp. 1275-1284.