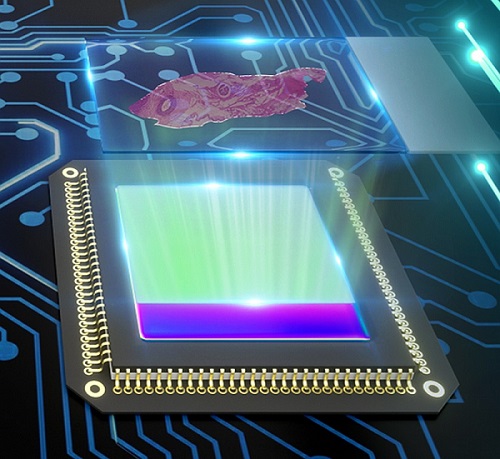

A resolution-enhanced parallel-coded ptychography technique developed by researchers at the University of Connecticut has achieved the highest numerical aperture and throughput to date, compared to previous demonstrations of similar technology. The approach replaces the objective lens with a disorder-engineered surface.

“The disorder-engineered surface can be viewed as a computational lens,” said Guoan Zheng, research leader and UConn professor of biomedical engineering. “The large-angle diffracted light from the object can be converted into smaller angles by the engineered surface, thereby facilitating superresolution imaging beyond the limit imposed by the image sensor.”

Graphic representation of the parallel-coded ptychography technique. The biospecimens are translated across the disorder-engineered surfaces on top of the image sensors for diffraction data acquisition. Courtesy of Guoan Zheng.

A conventional objective lens has an inherent trade-off between resolution and field of view. To achieve both high resolution and a wide field of view, one could increase the size of the lens. However, scaling up the lens would also scale up aberrations, requiring additional lenses for correction.

“The key advantage of the surface is the fabrication process,” Zheng told Photonics Media. Creating a metasurface with subwavelength scatters often requires electron beam lithography to define small patterns on photoresist.

“In contrast,” Zheng said, “a lithography-free fabrication process is developed to make the disorder-engineered surface in the prototype setup, enabling turnkey and scalable manufacturing at low cost.”

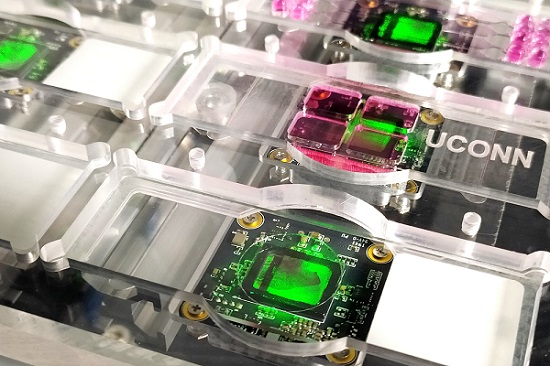

The scaling of complexity in array microscopy is a major obstacle preventing large-scale high-throughput imaging in biomedical applications, Zheng said. The prototype that he and his team developed is able to directly resolve the 308-nm linewidth on a resolution target without aperture synthesizing. It is able to acquire gigapixel high-resolution microscopic images with a 240-mm2 effective field of view in just 15 seconds, with a corresponding image acquisition throughput higher than that of the fastest whole slide scanner in the world.

For conventional whole slide scanners, quick and precise autofocus is a challenge. However, for the coded ptychography technology, this can be done post-acquisition.

“After the complex lightwave from the object is recovered, one can digitally propagate the lightwave back to any position along the axial direction,” Zheng said.

As such, autofocusing isn’t an issue.

The prototype device of the parallel-coded ptychography technique. Eight image sensors are operated in parallel for high-throughput lensless microscopy imaging. Courtesy of Guoan Zheng.

“One limitation of this technology, perhaps, is the computational cost of the recovery process,” Zheng said. “To process a large-scale gigapixel image, it often takes 20 minutes or longer in the current implementation.”

Zheng doesn’t expect that problem to remain, however, due to increasing capabilities of graphics processing units.

The technology is expected to have wide-reaching applications, including in digital pathology, where it can be used to acquire high-resolution centimeter-scale field of view images for diagnosis.

In clinical applications, the technology can cut down diagnostic time considerably for medical procedures requiring culture growth-based assessment. “For example, the platform can be used for tuberculosis, staph, and other bacterial infection diagnoses,” Zheng said. “The device can continuously and autonomously monitor for growth changes and notify the user to examine the sample when changes have been detected.”

Conventional microscopy is not an optimal technique for monitoring bacterial growth; using an upright microscope requires removal of the petri dish cover to gain access to the cells. Inverted microscopes are often unable to image through the agar layer. With the coded ptychography technology, however, the intact petri dish can be placed directly on the disorder-engineered surface for image acquisition.

The research was published in ACS Photonics (www.doi.org/10.1021/acsphotonics.1c01085).