JÉRÉMY PICOT-CLÉMENTE, EUROPEAN PHOTONICS INDUSTRY CONSORTIUM (EPIC)

The automotive industry has traditionally been at the fore of adopting emerging technologies to improve safety, performance, and user experience. In recent years, photonics has solidified its role as a transformative force in automotive lighting; photonics technologies provide significant benefits compared with traditional and legacy lighting systems, ranging from improved efficiency and longevity to overall design flexibility. Among the innovation areas driving these advantages are LEDs, OLEDs, and micro-LEDs as well as microlens arrays (MLAs) and color measurement technology.

LED solutions for automotive projection

LEDs generate light through electroluminescence, a process that involves the recombination of electrons and electron holes in an inorganic semiconductor. The wavelength of the light produced depends on the energy bandgap of the semiconductors used. The favored semiconductor material may be, for example, gallium arsenide (infrared); aluminum gallium arsenide (red); gallium phosphide (green); or zinc selenide (blue).

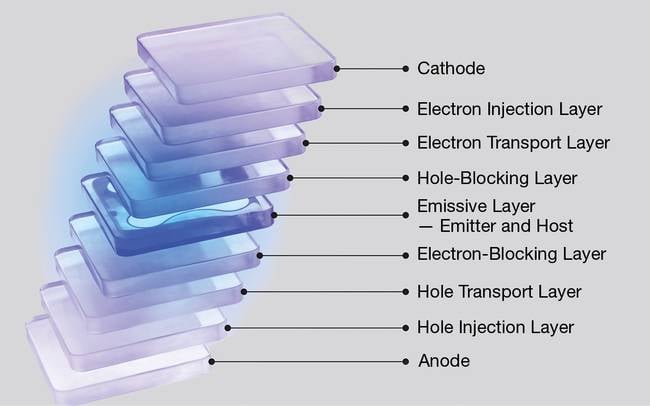

The subpixel scheme for an OLED display with the separation of individual layers. Blue emitters are necessary for electroluminescent displays as well as certain micro-LED displays that use ultraviolet LEDs as backplanes. Courtesy of Noctiluca.

A range of LED-enabled technologies is already incorporated into next-generation automotive display applications. California-based Luminus is one such developer of LED technologies, supporting augmented reality (AR) and holographic head-up displays, interior dynamic lighting, rear/side window displays, and dynamic ground projection. The company’s portfolio of LED solutions spans platforms (and wavelengths), with LED offerings from approximately 260 to 280 nm, to 610 to 950 nm.

Especially for digital light processing (DLP) applications, Luminus’ LED offerings benefit from the etendue — the required phase space of the area and the solid angle that is required to guarantee the loss-free transfer of light from one point to another within the optical system — matching with the DLP panel and system parameters. This allows for peak optical efficiency and maximum performance. The low thermal resistance package, which enables high reliability with passive cooling, is another advantage for DLP applications.

OLED advantages

An OLED functions in the same way as an LED, though, as its name implies, the present semiconductor material is organic. Commonly used materials include Tris (8-hydroxyquinoline)aluminum, polyfluorene, and triphenylamine.

The OLED display stack is made up of thin layers of organic materials, one of which, the emitter, converts electricity into visible light. This emitter and the additional organic materials combine to form a subpixel — the basic building block of an OLED display.

Torún, Poland-based Noctiluca is a designer and producer of these OLED emitters. In addition to its proprietary technology, Noctiluca markets ready-made product solutions, including compounds that can be combined with a finished OLED stack. This capability enables Noctiluca to select the optimal target material to increase OLED device efficiency for a given partner’s technology, while also optimizing the synthetic path and ultimately producing a new material for the customer. These materials may also find use beyond the display industry, in light sources.

Also, unlike LEDs, OLEDs can be synthesized from readily available and inexpensive precursors, which makes them inexpensive to produce. In addition, organic semiconductors can be dissolved in solvents, which makes it possible to deposit them onto a variety of substrates using solution-based techniques such as printing and inkjet printing. This quality enables the fabrication of devices with large active areas with more diffuse light sources that can be viewed directly, eliminating the need for shades, diffusers, lenses, shutters, and/or parabolic shells.

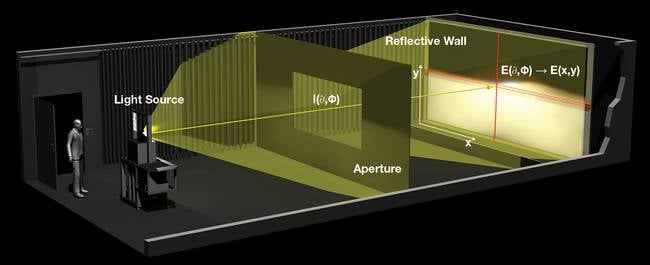

TechnoTeam’s ‘BV ROOM’ system returns luminous intensities, illuminances, and/or color coordinates as measurement results. The mechanism can be applied to automotive applications to yield color and light intesity measurments of interior and exterior illuminations. Courtesy of TechnoTeam.

Another Polish company active in the field of inorganic semiconductors is QNA Technology. The company specializes in the synthesis of quantum dots, heavy metal-free emitting blue light, and inks based on these dots. These inks include monomer-based ultraviolet (UV)-curable inks. Blue light emitters are essential in displays, particularly electroluminescent displays and in certain micro-LED displays that use ultraviolet LEDs as backplanes.

For automotive lighting applications, QNA offers PureBlue.dots in a colloidal solution consisting of quantum dots that are characterized by a limited toxicity and which can emit blue light in the range of 455 nm. This frequency is safe for the human eye and particularly important for displays. The company’s PureBlue.UV ink, one of its monomer-based UV curing inks, supports applications including light conversion or micro-LED fabrication, with the exact composition tailored to customer needs. This ink also contains pure blue quantum dots.

OLEDs are also widely used for displays and lighting systems in dashboard displays, holographic head-up displays, internal lighting, digital rear-view internal mirrors, and external lighting, such as taillights and indicators. Following Audi’s unveiling of the 2016 TT RS model, which can be fitted with optional OLED taillights, several subsequent models, including from Audi, adopted OLED lighting panels. Automakers, including BMW, Hongqi, Mercedes, and others have adopted OLED lighting panels in their designs.

Micro-LED applications and integration

Micro-LEDs are typically <100 µm and work much like traditional LEDs, though on a much smaller scale. When an electric current passes through a semiconductor material, it emits light. The core components are a semiconductor material, typically made of gallium nitride (GaN), and a substrate of sapphire, silicon, and/or GaN, on which the micro-LEDs are fabricated.

Micro-LED manufacturing is a highly specialized field that necessitates the development and use of advanced techniques to manage the tiny size and precise placement of each individual micro-LED. The intricate steps involved in micro-LED fabrication are substrate preparation, epitaxial growth, photolithography, etching, metal deposition, passivation, singulation, transfer, bonding, encapsulation, and packaging. Moreover, integrating finished micro-LEDs into existing systems and products also requires careful design and engineering. Ongoing advancements to overcome these fabrication challenges are increasing the viability of micro-LED technology for a wide range of applications, from high-resolution displays to automotive lighting.

These advancements complement the advantages of the technology: Compared with conventional LEDs or OLEDs, micro-LEDs can achieve higher levels of brightness in a smaller and more energy-efficient package. They also achieve better color accuracy and contrast, a faster response time, and a longer operational lifespan. Due to their size, micro-LEDs can be densely packed, enabling the creation of displays with high pixel densities.

One of the most influential applications of micro-LEDs in the automotive industry is in headlight systems. Traditional halogen and even standard LED headlights face limitations in terms of brightness, energy efficiency, and adaptability. By contrast, micro-LEDs offer adaptive beam control, adjustable dynamic light patterns to suit various driving conditions, and enhanced visibility. Further, micro-LEDs may be organized into arrays in which each LED or LED group can be individually controlled. Such a configuration allows for matrix headlights that can adapt to various driving scenarios as well as automatic switching between high and low beams by detecting the presence of other vehicles.

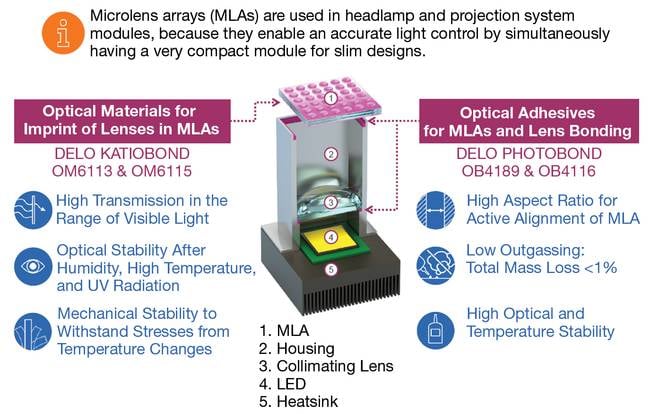

This complete microlens array (MLA)-based projection module includes an LED light source, collimation lens, and an MLA-based projection unit. Optical materials and adhesives are essential for the technical realization of this concept. The arrows in the image indicate the placement of the materials (left arrow) and adhesives (right and bottom arrows). Courtesy of DELO Industrial Adhesives LLC.

HELLA, an automotive supplier operating under the umbrella brand FORVIA, and the German luxury car manufacturer Porsche have co-launched a high-resolution headlamp. This solution is based on matrix micro-LED technology. In the forthcoming system from HELLA and the German automaker, the space required for the light module is reduced by up to 75% compared with conventional architectures. Additionally, the system features two high-resolution LED chips, smaller than a fingernail, that are equipped to generate >32,000 pixels per headlamp. The pixels are controlled by one electronic control unit for each headlamp. The system uses Gigabit Multimedia Serial Link (GMSL) interfaces to handle the high data volumes.

To control two light sources per headlamp with one control unit, HELLA has additionally developed algorithms that allow the light distribution to be calculated in real time. The digital headlamp system is debuting in the upcoming Porsche Cayenne models as an optional feature.

Microlens arrays

MLAs consist of multiple microscopic lenses arranged in a precise grid pattern on a single substrate. These lenses focus, collimate, and/or redirect light, providing enhanced control over light distribution. Compared with the projection of light through a single lens, MLAs enable very sharp and controlled projection under shallow angles. There is another added benefit: a lower distance between the light source and the optics. In addition, the high precision and efficiency qualities of MLAs make them ideal for numerous lighting applications in modern vehicles, including headlamps.

The fabrication of MLAs is achieved via a wafer-level imprint process involving first dispensing a UV-curable polymer onto a glass substrate. This is followed by imprinting, UV curing, and dicing of the finished wafer.

The properties of the polymer used are fundamental to the performance of the MLA. The polymer(s) must have high transmission in the visible range and excellent optical stability at elevated temperatures, as well as during UV exposure. Also, they must exhibit low shrinkage in combination with excellent adhesion to glass and simultaneous debonding from stamp materials. And at the same time, the mechanical properties must be suited to withstand stresses from temperature changes and vibration. As a result, adaptations to polymers serve as the nuances to this manufacturing process.

The specially adapted polymers from Germany-based DELO, for example, support the wafer-level imprint process that meet these demanding requirements, and they are effective for multiple applications in the automotive sector. The company’s solutions for MLA LED headlamps also address additional considerations. These considerations include MLA-to-housing bonding, active alignment of primary optics, and lens bonding.

MLA deployments enable other innovations. Focuslight Technologies, based in Xi’an, China, is a developer and manufacturer of high-power diode laser components and materials. The company now produces MLAs for ground projection applications and headlamp applications, integrating its solution into commercially available headlamps. The technology is also under investigations as a solution to create very slim headlamps down to a lens height of 10 mm.

Color measurement

Color measurements in the auto sector are necessary to determine values of the luminance and luminous intensity of headlamps, daytime running lights, and other light sources. Glare and ambient light are potentially hazardous occurrences that can be assessed in terms of color.

TechnoTeam, a developer of light and color measurement systems, provides spatially resolved measurement technology in the form of digital camera systems, which allows for complex analyses of lighting situations in relation to luminance, luminous intensity, illuminance, color values, contrasts, and other photometric perception criteria. In automotive applications, these systems are used for the quality assurance of interior lighting in respect to luminance, color, and homogeneity.

Still, this type of objective measurement — of light and color — is even more important for exterior lighting, because exterior lighting must conform to precise specifications as defined by standardization bodies.

Prospects and challenges

Ongoing advancements in the automotive industry will continue to transform photonics’ role for this field. Emerging trends promise to revolutionize vehicle illumination systems, enhancing safety, functionality, and user experience.

One such innovation is the advent of AR headlights capable of overlaying critical information directly onto the road, offering drivers real-time navigation guidance and hazard warnings. This improves driver awareness and integrates seamlessly with smart vehicle ecosystems.

Additionally, integrated front lighting systems coupled with lidar are poised to enable obstacle detection and road condition assessments with unparalleled precision. At the same time, vehicle-to-vehicle communication facilitated by light signals will enable efficient data exchange between vehicles for enhanced traffic management and safety protocols.

Despite these advantages, several challenges remain to the widespread adoption of advanced photonics technology solutions in automotive lighting. The complexity of manufacturing micro-LEDs, and the precision engineering and integration requirements of diverse photonics components, for example, require continuous refinement to meet stringent automotive standards for reliability, durability, and regulatory compliance.

Even amid the challenges, the demand for integrated lighting solutions that communicate and interact with other vehicle systems will continue to increase as vehicles become increasingly connected and autonomous. This drives ongoing R&D to ensure the seamless integration of photonics technologies into the broader ecosystem of smart vehicles.

Addressing these challenges will require interindustry collaboration, continued investment in R&D, and advancements in manufacturing processes. By overcoming these obstacles, the automotive industry can unlock the full potential of photonics to create safer, smarter, and more efficient vehicles for the future.