The metrology method should match the nature of the part and the inspection constraints.

Matthias Knobl, Edmund Optics Inc.

The benefits of aspheric lenses are numerous: They allow for a reduction in spherical aberrations and are ideal for focusing or collimating light, as they can achieve a low ƒ-number. Aspheres also allow the same or better performance using fewer lenses, which often translates to a reduction in both size and weight in a system.

New applications in imaging increasingly require the use of aspheres, due to performance and size constraints. As standalone items in laser applications for focusing or collimating, aspheres are also the best performing option. Manufacturing these surfaces requires equally innovative metrology methods, even more so because the manufacturing process is deterministic, with corrective iterations guided by measurement data, in order to provide high-quality results. It is important to assess the strengths and weaknesses of the available metrology methods that are used to quantify the surface accuracy of aspheres, and identify the criteria for selecting the most appropriate technique to measure specific classes of optical surfaces.

Stock aspheric lenses are designed to maximize performance in various applications, for example high-power Nd:YAG laser systems. Custom options for OEM systems are also available.

The most common piece of surface metrology in optics manufacturing is an interferometer. When used for planar or spherical parts, the system is one-shot capable, i.e., the full surface is covered at once, given a sufficiently large system aperture. In principle, the interferometer is a comparative technique, which means that in order to determine the surface accuracy of optical components, a planar reference wave is required to measure planar parts, or a spherical reference wave to measure spherical parts. For both cases, a wide choice of suitable, high-quality reference objects is commercially available, but neither of these references are viable for measuring aspheres. Even compared to the best-fit sphere, the aspheric departure is so significant for typical designs that it creates very densely spaced interference fringes which are challenging to resolve. This fundamental limitation leads to the requirement of specialized metrology solutions for aspheres, which we will discuss in the following.

There are three ways to tackle the problem:

1. Create an aspheric reference for the interferometer, keeping its one-shot measurement capability.

2. Divide the surface into sufficiently small segments to measure them against a spherical reference and stitch them together, to recreate the full asphere.

3. Scan the surface, using a sufficiently precise point sensor and kinematic.

All options come with their own advantages and disadvantages, so it is important to choose the right tool for the job at hand.

For option 1, aspheric reference surfaces are typically realized by computer generated holograms (CGHs). The spherical wavefront from the transmission element of the interferometer is altered by a CGH to form an aspheric wavefront that exactly matches the nominal optic surface profile. This is done by using diffractive optical elements, manufactured using lithography techniques, to create a null reference wave. The surface accuracy that can be measured may be limited by the transmission element used with the interferometer or by the density of diffractive features that can be manufactured onto the CGH. A new CGH must be purchased for each asphere design, so this is a prohibitively expensive test method except for parts that are not made in high production volumes. Once the CGH is aligned, testing a part can be completed in a few minutes, thanks to the system’s one-shot capability. CGHs are not able to test parts that have points of inflection and will not provide accurate data on the radius of curvature of the optic without additional precision location measurements of the test part along the optical axis.

A way around creating costly, design specific references is stitching interferometry, listed as option 2. This method uses standard phase shifting interferometry on smaller subsections of the lens, and then uses software to stitch the pieces together. The subapertures have to be chosen appropriately, to ensure that the aspheric deviation against the available reference remains small enough to resolve the full fringe pattern. The measurements also need to be taken with enough overlap, to allow the software to accurately piece them together. The reference waves can be purely spherical or include specifically induced aberrations.

The shape of the subapertures can vary and different solutions are possible. A machine may use overlapping circular subapertures to form a complete map, others may use concentric rings to form the total measurement. The machine is capable of removing its own system errors, so a highly accurate map of the surface can be achieved. Stitching interferometry is often limited by part geometry and may struggle to measure lenses with large aspheric departure or steep slopes. Some lenses may require in the range of 100 individual subapertures, so measurement times may take upward of 20 minutes per part. It may be necessary to purchase a wide range of transmission elements with different focal lengths in order to accommodate a variety of geometries of the manufactured parts, and the systems are costly, incorporating the base interferometer, accurate kinematics to move from aperture to aperture, and advanced software algorithms to minimize stitching errors.

The third group of solutions, “scanning systems”, is by far the most varied one. Broken down to its basics, it includes any system that will use some sort of sensor to locate the optical surface position in one point only and then move the sensor across the surface in a specific pattern, to determine the full profile.

The scanning can be 2-dimensional or 3-dimensional, linear, circles, or spirals, — various solutions are possible. What is more important: In order to achieve high accuracy, scanning systems require very precise motion control and smart ways to reference the current position. A good sensor alone is important, but not sufficient. These requirements for the mechanical setup drive the price up for systems that are supposed to achieve accuracies well below 0.5 micrometer. In return, they allow great flexibility in the range of shapes that can be measured. Full hemispheres, large aspheric departures, and points of inflection will not pose a problem. Depending on size and the chosen point density for scanning, the measurement of aspheric parts can take up to around 20 minutes.

Sensor options include tactile sensors in contact with the surface or noncontact options, as represented by all kinds of optical sensors. We will have a closer look at two of them: Multiwavelength interferometry and chromatic confocal sensing.

The simplest implementation of a scanning system in the wider sense is 2D-contact profilometry. In such a system, a stylus is physically dragged across the surface of an optic. The other end of the stylus features a diffraction grating. Using the deflection of a laser directed toward the grating, the displacement of the stylus is recorded in a 2D trace. Contact profilometry is ideal for ground optics that do not reflect enough light to be measured with standard interferometry. Because the stylus is in contact with the optic, there are very few limitations to what shapes can be measured in terms of aspheric departure and points of inflection, although very steep slopes may not be measurable.

Contact profilometry has long been the industry standard to measure aspheric surfaces and it is cost-effective, but the method has some serious shortcomings: A single line through the center of a lens will not give an accurate depiction unless the errors in the lens are completely rotationally symmetric, which is rarely the case. This can lead to a misrepresentation of the part in question, as illustrated in Figure 1, giving a numerical example for an astigmatic lens.

Although it is possible to take multiple traces at different orientations, this is time-consuming and will still lead to large untested areas. In addition, because the stylus is in physical contact with the part, there may be a possibility of damaging softer materials or coatings if too much pressure is applied. For these reasons, it is advantageous to explore asphere metrology that derives its measurements from noncontact 3D surface profiles.

Figure 1. Interferogram with sample 2D traces. (Left) Horizontal: PV = 0.790λ, rms = 0.195λ. (Right) Diagonal: PV = 1.841λ, rms = 0.546λ. (PV = peak-to-valley, rms = root mean square). Courtesy of Edmund Optics.

Chromatic confocal sensing uses a chromatic pen that emits white light to take distance measurements. Due to dispersion, which is the difference in index of refraction in a glass based on wavelength, the focal length of an uncorrected lens will vary by wavelength. This causes different wavelengths of light to focus at different axial distances. Usually, this chromatic aberration is an error that must be compensated for, but in chromatic confocal sensing, the effect is critical. Based on the wavelength of the light that is in focus after it was reflected back from the optic under test to the sensor, the distance between surface and sensor can be determined. Now, the sensor needs to be moved along a trajectory that follows the idealized shape of the optic, while its distance to the surface is constantly recorded. This produces the desired surface error map.

Alternatively, multiwavelength interferometry uses the well-known practice of performing distance measurements through interference effects, and adds additional, tightly spaced wavelengths to increase the unambiguous measurement range. Designed as a point sensor, it can be used in the same fashion as the chromatic confocal sensor, but with greater measurement accuracy on the sensor side. Included in a precisely referenced scanning system, this yields a flexible system with high precision.

If you can’t measure it, you can’t make it. Metrology capabilities and manufacturing capabilities go hand in hand, especially for aspheres.

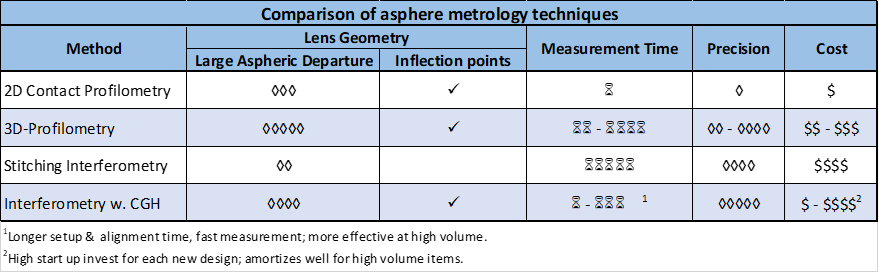

A comparison of the capabilities of the methods of asphere metrology discussed in this article is available in the accompanying table as a guide for selecting a machine based on the primary concerns of the operation.

The use of aspheres continues to grow in applications that have requirements including aberration minimization, high-resolution imaging with fewer optical components, and elements with low ƒ-numbers. Various techniques for surface metrology on aspheres can be found in the market today, each with their own strengths and weaknesses.

With increasingly tight requirements for asphere surface accuracy on the one hand, and cost-effective production on the other, it is important to consider what method of asphere metrology is best-suited to the application at hand. Having a choice of metrology systems available can be a big advantage for manufacturers and their customers.