From heat-assisted magnetic recording to magnetic random-access memory, low-power lasers are boosting data capabilities for AI and beyond.

JAMES SCHLETT, CONTRIBUTING EDITOR

Last spring, electronics giant Toshiba announced its plans to ship its first test sample hard disk drives (HDDs) using heat-assisted magnetic recording (HAMR) technology. Toshiba, at the time of the announcement, said that it is targeting 2025 for the shipment.

Courtesy of iStock.com/Remitski.

The decision as well as the technological advancement represent an emerging movement in the data storage and photonics industries. Toshiba’s debut of its HAMR HDDs, with 28 to 30 Tb of storage, follows Seagate Technology’s rollout of similar technology in 2017, following 15 years of research.

With Toshiba and Seagate expecting to be working toward mass-producing HAMR HDDs with 32 Tb of storage capacity by next year, industry analysts predict that more than half of all drives shipped in 2027 will be using this next-generation, large-capacity magnetic recording technology. And HAMR’s share of the HDD market could be even greater if this technology is incorporated into drives made by Western Digital — which said in mid-2023 that it was at least one-and-a-half years from achieving volume production of this technology.

Despite the magnetic foundation of HDDs, these developments signal a growing opportunity for low-power lasers, which serve as the heat source for HAMR. For example, Seagate’s HAMR HDDs use a low-power NIR Fabry-Pérot laser. The use of lasers for the flipping, or “switching,” of data bits represents a shift from the industry-standard, perpendicular magnetic recording. In this legacy mechanism, a recording head’s write pole creates a perpendicular magnetic field to switch the recording media.

HAMR

HAMR was conceptually proposed in the 1990s, and in 2002, Seagate began to strive for its commercialization. In HAMR, the laser function helps drive an increase in the areal density, which is the number of data bits per unit area on a disk platter. One challenge associated with increasing areal density is that if the bits are too close together, they can affect each other’s magnetic direction. HAMR systems use a laser to rapidly heat the magnetic media to enable the recording head to switch bits in the higher magnetic energy (coercivity) materials.

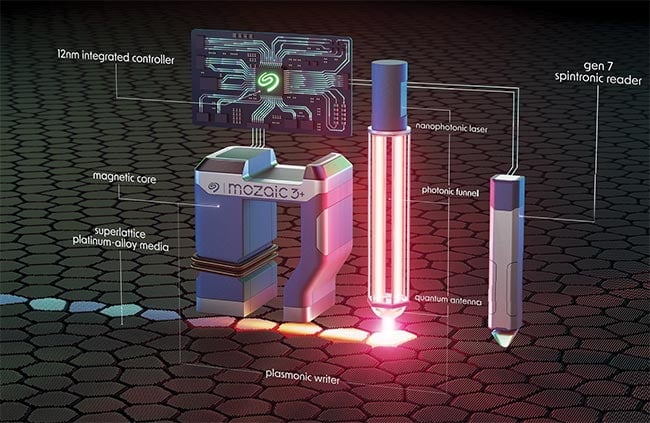

Seagate Technology’s heat-assisted magnetic recording (HAMR) hard disk drives (HDDs) include a plasmonic writer with a precision-engineered laser that heats and writes the media to >800 °F and cools it down in <2 ns. Courtesy of Seagate Technology.

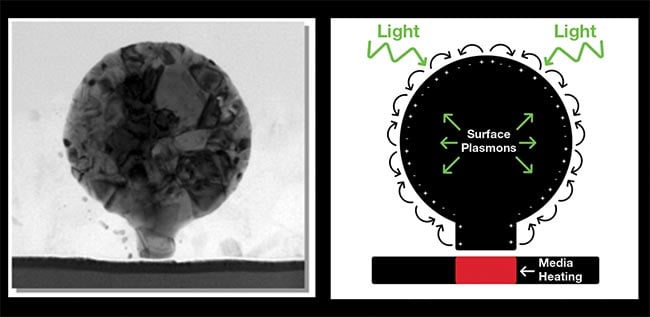

“A Fabry-Pérot laser is coupled into a waveguide, which provides the proper phase and intensity distribution to excite a plasmonic resonance on the near-field transducer,” said Ed Gage, vice president of Seagate Research Group. Fundamentally, the low-power sources offer an assist in this technology. “The electrons in the metallic peg at the bottom of the transducer move in a way to excite an electric field in the recording media. The media is made of a poor metallic conductor, so the media get[s] very hot very quickly [and] then [it] cools down very quickly as well.”

According to Seagate, the typical recording power from the laser is on the order of 10 mW. For HAMR, the laser power must be high enough to raise the recording medium close to its Curie temperature, which is nearly 500 °C in iron-platinum (FePt)-ordered alloys, said Ernesto Marinero, a professor of materials engineering at Purdue University. “The laser power must be sufficient to provide the power density at the near-field transducer to raise the medium temperature in the vicinity of the Curie temperature, but also to compensate for reflectivity losses and coupling efficiency of all the optical components involved in guiding light from the laser to the near-field transducer,” he said.

According to Gage, the lasers in Seagate’s HAMR HDD account for <1% of the drive’s power consumption, resulting in a significantly lower storage per power (Tb/W) rate compared with competing technologies. For HAMR, said Richard Evans, a professor of physics at the University of York, the laser spot is tiny (~100 nm). This makes the local heating especially strong.

Gage said that laser efficiency improvements could further reduce the power and heat generated in the recording head, and that Seagate is evaluating advancements in other low-power laser diode technologies. Single-mode VCSEL technology would also be of interest, though, in this case, with an increase in available laser power, he said.

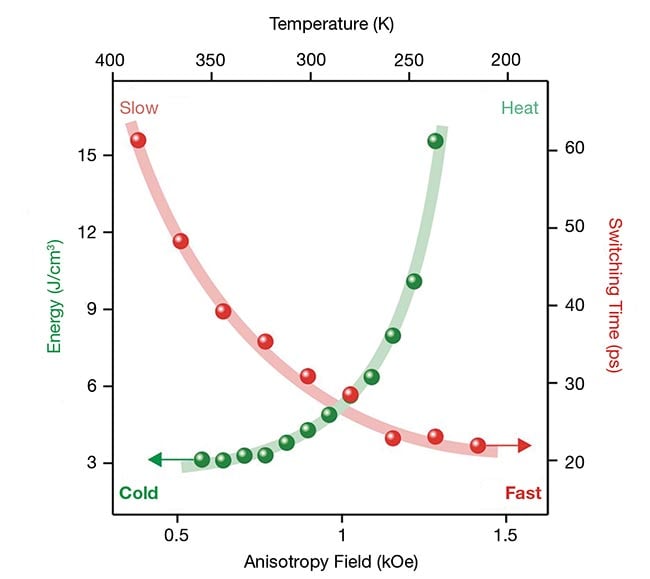

In 2024, researchers in Poland and the Netherlands demonstrated cold all-optical toggle switching of magnetization. The green dots show minimum heat load accompanying the switching as functions of temperature. The red dots show corresponding switching time as a function of temperature. Courtesy of University of Bialystok.

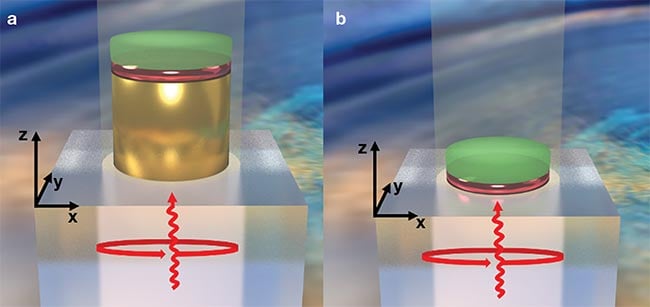

Purdue University researchers proposed CMOS-compatible plasmonic materials for on-chip magnetization reversal in nanomagnets. A nanodisk includes a plasmonic antenna (left, yellow); a thin magnetic layer (burgundy); and a capping layer (green). A nanomagnet and capping layer, without the plasmonic antenna, shows circularly polarized light (right, right-pointed arrow). The curled arrow shows incidence direction. Courtesy of Purdue University.

Marinero said that the path to further reducing laser power in the future hinges on improvements to losses of the optics guiding the laser beam to the near-field transducer. Laser power reduction could also involve lowering the recording medium’s Curie temperature. However, the relationship between the Curie temperature and the medium’s structural and magnetic properties would present a challenge.

The combination of HAMR and bit-patterned media (BPM), which involves lithographically defined “magnetic islands” of bits, could present an option to boost storage capacity of 50 Tb or greater. In 2012, for example, Marinero was part of the team of researchers at Western Digital that used direct electron-beam lithography to fabricate 1 Teradot/in.2 cobalt-chrome-platinum alloy BPM disks, on which magnetic recording was performed.

“This technology is currently [on] the [shelf] for future solutions once the limits of HAMR-alone magnetic recording are reached and the cost of BPM mass production is attractive to the market,” Marinero said.

Cold magnetic storage

Lower laser energy consumption in writing data can also be used through all-optical magnetic switching with femtosecond laser pulses. Last year, researchers from the University of Bialystok (Poland) and Radboud University’s (Netherlands) Institute for Molecules and Materials

demonstrated laser-induced toggle switching without relying on heat. For this “cold” magnetic storage, the researchers used a commercial ultrafast system with high energy per pulse.

While noncommercial, all-optical switching of metallic systems has been demonstrated, its minimum heat load, or volume energy needed for the switching, was ~1500 J/cm3. Previously, switching without such heat seemed unrealistic,

said Andrzej Stupakiewicz, a physics professor at the University of Bialystok. According to Stupakiewicz, the researchers’ approach from the 2024 work considerably outperformed existing alternatives, both in the speed of the write-read

magnetic recording event and in a negligible heat load.

At Purdue, researchers are also examining “cold” recording as it relates to all-optical magnetic switching and using femtosecond laser pulses in their efforts. Marinero said researchers at the university have conducted modeling studies that validate these ultrafast lasers (in combination with surface plasmons) to generate intense opto-magnetic fields. Such studies support an approach that would drastically reduce the laser energy required for writing data, he said. However, the commercialization of such technology is years away, though it could accelerate as HAMR reaches its technical limits.

As for potential application areas, Stupakiewicz said prime opportunities for cold magnetic storage are emerging in superconducting electronics, quantum compute, and AI, because applications in these domains face energy consumption challenges. Traditional metallic technologies also lack the speed and frequency for CPU or storage due to material cooling delays for equilibrium thermodynamics after switching bit states.

Single-pulse toggle switching

The International Data Agency estimates global data to swell to 163 Zb (zettabytes) by 2025, compared with 16.1 Zb in 2015. Currently, the data storage industry is facing pressures to not only lower energy consumption through the deployment

of low-power lasers but also to increase data speeds. Cognitive systems, such as machine learning and AI, and the continued expansion of mobile and real-time data and embedded systems and Internet of Things, are among the drivers behind this rise in demand.

Femtosecond lasers are positioned to meet these data storage requirements, particularly through single-pulse all-optical switching of magnetization. While femtosecond lasers may seem like high-power options, their requisite energy power in single-pulse switching magnetization over individual magnetic bits is much less than the power found in existing technologies, such as hard drives and/or flash memory (10 nJ), said Chuangtang Wang, a physics research fellow at the University of Michigan.

“Femtosecond laser switching of magnetization requires the laser-heating of materials to near Curie temperature (above 1000 K for ferromagnetic Co/Pt [cobalt/platinum] multilayer) in tens or hundreds of femtoseconds. Therefore, high-pulse energy is needed, [typically on the] order of several mJ/cm2 (mW over focused laser spot),” Wang said. “Therefore, an optical parametric amplifier laser is typically used so the frequency is on the order of kilohertz.”

To date, single-pulse toggle switching is achieved with ferrimagnets, which have low anisotropy. This limits their applicability to magnetic data storage due to thermal instability. In contrast, ultrafast magnetic switching has been demonstrated with ferromagnets that have high anisotropy. But this requires multiple pulses.

According to Evans, the current need is for high anisotropy materials, such as FePt, that are switchable by all-optical means. As it relates to FePt, single-shot switching has yet to be achieved — and this is necessary for it to work as a technology, he said.

“The solution lies in advanced/composite materials and greater physical understanding of all the mechanisms at play — for example, ultrafast currents and magnons as well as angular momentum transfer,” Evans said. In 2014, Evans was part of a team that developed a synthetic ferrimagnet that sandwiched two ferro-

magnetic materials and a nonmagnetic spacer layer. Single-pulse magnetic switching was achieved with this synthetic ferrimagnet. Since then, synthetic ferrimagnets have been fabricated, but Evans said challenges remain in engineering a strong antiferromagnet coupling between layers.

Opto-magnetic random-access memory

All-optical switching schemes in synthetic ferrimagnetic multilayers are also creating opportunities for femtosecond

lasers in magnetic random-access memory (MRAM), following a demonstration by researchers at Eindhoven University of Technology in 2017. Previously, magnetic memory writing could only be achieved by electrical means.

“Opto-MRAM introduces lasers into this process to manipulate the magnetic states. Instead of using electrical currents, ultrafast laser pulses induce magnetic switching via all-optical switching,” said Luding Wang, an assistant professor at Tohoku University.

“This allows for [the] magnetic switching process to overcome the traditional spin precession process. A femtosecond laser interacts with atoms at nonequilibrium thermal states, allowing for efficient spin transfer faster in picosecond compared to traditional MRAM,” Wang said.

For opto-MRAM, the laser’s typical pulse duration is 100 fs and wavelengths are in the visible or NIR spectra (around 800 to 1000 nm). It uses extremely low energy, on the order of picojoules per pulse.

“Femtosecond lasers offer energy

savings because they can switch magnetic states using ultrashort pulses of light with minimal power consumption,” Wang said. “These savings are especially important for data centers and high-performance computing systems, where energy efficiency directly impacts operational costs and environmental footprint.

“As demand for faster, more energy-efficient memory grows, opto-MRAM and similar technologies will become more attractive.”