There are many factors involved with selecting laser protective eyewear. This article discusses those factors and helps the user make the right choice.

Ken Barat, Laser Safety Solutions

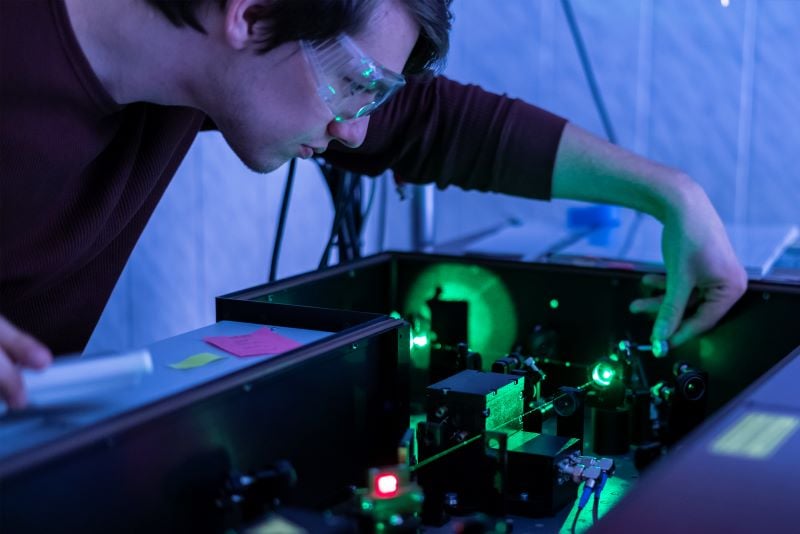

An overwhelming number of those who regularly use lasers readily associate laser eyewear with the term “laser safety.” Of course, laser safety envelops much more than protective gear. “Beam control” and “remote viewing,” for example, both point to concepts that ensure far more effective means of protection.

Still, when the conversation does shift to laser protective eyewear, several factors can help determine the best option for all users.

Laser considerations

For any discussion about the selection of laser protective eyewear, one must determine optical density. This unitless parameter is defined as the log ratio of the incident beam over the transmitted beam. Factors that go into this calculation vary, depending on whether the beam is continuous wave or pulsed. From this information, users can then properly calculate optical density (accordingly, a unitless value) for each wavelength from which eye protection is needed.

If a user selects a protective filter based solely upon wavelength and optical density, the selection will be satisfactory. “Satisfactory,” however, is not always sufficient to ensure user safety in an active beam environment. Users must also account for visible light transmission (VLT). This value refers to how much visible light penetrates the eyewear filter; depending on the dye, filter coating, and/or the eyewear material, VLT can be as low as 1%, or as high as 96%. The number of distinct wavelengths that a filter is designed to block is another factor influencing the VLT value. The European Normal 207 (EN207) regulations on eyewear list a minimum acceptable VLT of ~20% for a well-lit room. As a result, it is contingent upon the laser safety officer to consider the lighting conditions for all users in any setting.

To illustrate best practices for selecting a filter, consider that a traditional plastic filter for a 1064-nm source is a green tint. If a glass filter is selected, the filter is almost clear. So, if visibility is critical, a heavier glass filter is the best choice. But, as described, the weight of the filter and frame are typically such that straps on the eyewear are required to ensure a proper fit. This may introduce the potential for user fatigue. To resolve this issue, a gray plastic filter covering 1064 nm is now on the market — and I expect that it will become the standard filter for 1064-nm users.

Reflective filters, as a rule, provide a higher VLT than dye-based filters. But, just like their name suggests, reflective filters can reflect beams onto others. Overall, glass filters will always offer greater VLT but will also be heavier on the face. In fact, the majority of laser accidents in academic, research, and/or fabrication settings occur when eyewear is available but not worn.

Color and fit

Sometimes, too much of a good thing can be a problem. When optical density is provided by a tinted dye, using eyewear with an optical density value beyond that of what is needed will ultimately reduce VLT, as a result of a darkened filter.

This is to say that to truly perceive VLT, one cannot rely strictly on the numbers. Some color filters — gray, blue, and yellow, for example — yield an enhanced or perceived visibility.

Frame fit is another often overlooked factor in eyewear selection. Not every filter comes in every frame style. This is due to the limitation of obtaining an even coating if the frame style curvature is too severe, as is the case with some wrap-around frames. This is why some filters only come with a limited number of frame styles.

Another important aspect of frame fit is tightness to the bridge of the user’s nose; obviously, eyewear that slips down the nose does not provide quality eye protection. The easiest solution is to use (properly fitting) straps that will hold eyewear in place. Also, several frame styles, including adjustable frames, are now available on the market. Beyond the fit to the nose, it is critical to eliminate the gaps in eyewear frames that can occur around the temples or below the lens.

Visual acuity is a new-to-emerge consideration related to VLT. This gauge describes exactly how well one can see through the filter. For example, think of the yellow, night-time glasses that cut headlight glare. The actual visual acuity of these glasses (more specifically, their lenses) is low, since they cut much of the blue visible spectrum while still offering enhanced vision.

Eyewear unveiled

There are many additional qualities, considerations, and pieces of information that users should evaluate before making an eyewear selection. Ultraviolet bleaching tops this list. UV exposure, from use in outdoor settings, as well as germicidal lamps, biosafety hoods, curing lamps, plasmas, and xenon lamps, can cause the laser eyewear lens to darken over time. It can also cause optical density to decrease by a value of one or two. This can cause a polycarbonate lens to become brittle, which increases the chances of breakage. Laser eyewear used outdoors in bright sunlight can exhibit these effects in as little as two to four months.

The above items are present in the ANSI Z136.1 Safe Use of Lasers standard 2014 edition: According to Section 4, UV radiation degrades polycarbonate, lowers the optical density at the protected wavelengths, and alters the spectral transmittance of dye-based technologies. For example, after 200 h in a solar chamber, which equates to ~500 h of actual use, a dye-doped polycarbonate substrate may no longer provide ballistics protection, and the optical density may have dropped by 1 or 2.

Impact resistance is a facet of eyewear assessment and selection that may surprise many users, since laser protective eyewear is only required to meet the same impact resistant standard as commercial sunglasses, ANSI Z80.3. Such placement traces back to early laser protective eyewear, which was not shatterproof. Ultimately, if impact resistance is important for one’s laser use environment, if not labeled Z87 or Z87.1, do not assume that the eyewear is suitable for use.

Further, depending on the lens material and frame design, the optical density of the eyewear is not uniform across the surface of the lens. Therefore, the angle of exposure will influence the effectiveness of the eyewear filter. The labeled optical density is for laser radiation entering a set acceptance angle range. Laser radiation that is incidental upon the eyewear outside that angle will yield a diminished optical density. The obliqueness of the angle, and where the eye is looking, will influence the level of laser radiation entering the pupil.

An additional consideration for users of laser protective eyewear pertains to users who wear glasses. Users who require prescription glasses have several options for eyewear, including eyewear with prescriptions ground into the glass laser lens, over the frame eyewear, eyewear that holds prescription inserts, and eyewear with flips that have polymer prescriptions in the base or the flip.

Humidity and temperature

Humidity, such as what is present for medical sterilization processes, can have an adverse effect on the optical density of protective eyewear. The eyewear standard Z136.7 requires that light transmittance and specified optical density of the filter shall not decrease by more than 10% from the manufacturer’s stated numbers when exposed to expected work humidity levels.

Temperature is also apt to influence the function and useful lifetime of laser protective eyewear. Though it often goes unsaid, temperature range will affect the laser system. But laser systems are used in a variety of settings that have temperature ranges above and below what is considered “normal” room temperature. Still, elevated temperatures, which can be found in many industrial settings, can cause significant spectral shifting. Both dyes and reflective technologies are highly susceptible to high temperature. Reflective technologies usually cannot tolerate temperatures over 122 °F ±2 °F (50 °C ±1 °C). Meanwhile, low temperatures can cause reflective technologies to crack or delaminate. Reflective technologies usually cannot tolerate temperatures lower than -4 °F ±2 °F (20 °C ±1 °C).

Eyewear cleaning

The Pandemic heightened concerns around eyewear disinfection. But even before the pandemic, this was an extremely important consideration, especially in situations in which eyewear is shared. The cleaning of eyewear has always been recommended — and not just to remove dust and fingerprint smudges.

Cleaning is not a simple act. Eyewear cannot be treated with a chemical that may remove its protective coating. The same logic applies for chemicals that may affect frame material and reduce the eyewear’s lifetime. Bleach, for example, can break down rubber and cause it to become sticky. Acetate and cellulose materials are a better solution.

Prior to cleaning eyewear, make sure hands are clean using warm, soapy water. Several eyewear vendors offer disinfection recommendations on their products. If you are using some type of alcohol, keep in mind the Centers for Disease Control recommendation of 70%, which is much higher than the typical isopropyl alcohol wipes.

Conclusions

On the surface, it may seem that since many lasers produce multiple wavelengths, it is difficult to find the proper laser protective eyewear. The most suitable solution is to consider more than one pair of eyewear, if necessary. But there are still several easy-to-miss factors to consider when selecting the appropriate eyewear.

First, beware of the 800-nm trap (I use this term for wavelengths in the 750-850-nm range). Visual perception of these wavelengths by the human eye is less than 1%. Think of an iceberg: Only a sliver may float above the waterline, with the real danger beneath the surface. Many laser accidents have occurred when users visualized a faint 800-nm beam spot and assumed that it was just a weak reflection. Remember, if you are capable of perceiving less than 1%, and you can see the beam, a lot of energy is likely to be present.

Consider also that the National Institute of Standards and Technology (NIST) has reaffirmed that ultrafast pulses are faster than the relaxation time of most absorptive dyes used in eyewear. As a result, listed optical densities may not hold up in use. A better solution falls in beam containment and awareness.

Finally, users ought to know that all laser eyewear will eventually fail. No pair of laser protective eyewear, neither plastic nor glass, is made to endlessly stare down a rogue band of photons.