By Andreas Thoss

There’s no doubt that the world is in turmoil. High tariffs are threatening global trade, missiles are flying through the air, and climate change is no longer a looming threat — it is our daily reality.

Amid this global backdrop, the vibrancy of LASER World of PHOTONICS felt surprising, even uplifting. From show organizers, exhibitors, and perhaps most noticeably from the community, the mood in the halls was upbeat, despite the fact that many companies are facing severe challenges.

We are living in the century of light. The industrial manifestation of photonics is clearly on the rise. As a major photonics trade show, LASER 2025 grew by 10% compared to 2023. A total of 1398 exhibitors from 41 countries showcased the full spectrum of photonics technologies to ~44,000 visitors. The co-located events — automatica, the World of QUANTUM, and the World of Photonics Congress — were thriving as well. Almost every exhibitor with whom I spoke reported high booth traffic and strong leads.

Against what felt like all odds, the show was a complete success.

LASER World of PHOTONICS 2025 — co-located with the World of QUANTUM, the World of Photonics Congress, and automatica events — posted record numbers with 1398 exhibitors and 44,000 visitors. Courtesy of Messe München GmbH.

A wonderful world

In the lead-up to the week of the trade show, on Friday, June 20, the eyes of the photonics world focused intently on Ditzingen, Germany, the site of the Berthold Leibinger Zukunftspreis (Future Prize) and Innovationspreis (Innovation Prize) ceremony. At TRUMPF’s headquarters, Peter Leibinger, chairman of the Supervisory Board of TRUMPF SE, welcomed more than 600 invited guests. Berthold Leibinger, Peter’s father, transformed TRUMPF into a global leader in industrial laser technology. With his foundation, he sought to honor outstanding achievements in both basic and applied laser research.

Sobering news, though, cast a shadow over this year’s ceremony: TRUMPF recently announced significant layoffs. And, of course, the global backdrop remains grim. “Shall we celebrate in these times?” Peter Leibinger asked the audience. His answer was a thoughtful and heartfelt yes.

He reminded us that international exchange has never been more essential. It is precisely in difficult times such as these, he said, that we must honor scientific excellence. And above all, Peter Leibinger affirmed his deep appreciation for this world, calling it “wunderbar” (marvelous).

The evening unfolded as a joyful celebration of light and science; a gathering of more than 600 laser enthusiasts shared inspiration, purpose, and a bit of much-needed optimism. It served as a strong inspiration for the forthcoming week, as the photonics world traveled to Munich.

A visit to the future of ultrafast lasers

Like Photonics West in January, LASER World of PHOTONICS in Munich kicked off on a Tuesday, leaving Monday free for a visit to one of the city’s many photonics hotspots. Munich is home to world-class research centers, including the famed Max Planck Institute of Quantum Optics, in Garching. This year, though, I opted to visit a company that has been on my wish list for years: TRUMPF Scientific Lasers.

Among the companies in the industrial laser ecosystem, this spinoff has a unique advantage: It can draw from the full TRUMPF portfolio and change (or add) whatever its experts deem necessary to create lasers with extreme specifications tailored to specific scientific pursuits.

“We often sell lasers that don’t exist,” CEO Tom Metzger said regarding the team’s daily mission. The results are high-performance systems that deliver ultrashort pulses at high repetition rates, offering tens of thousands of hours of uptime.

Most of TRUMPF Scientific Lasers’ systems are based on ytterbium-doped YAG (Yb:YAG), a material that is favored for its diode-pumping efficiency. The drawback, of course, is Yb:YAG’s relatively narrow bandwidth. To achieve pulse durations that are 50 fs or less, the company uses nonlinear devices for spectral broadening, resulting in minimal loss due to the use of a Herriott cell. One such cell, stretching an impressive 12 m, dominates a large part of the lab. It is clear that this approach has practical limits.

Tom Metzger, CEO of TRUMPF Scientific Lasers, presents a 10-J, 100-Hz amplifier head based on multiple ytterbium-doped YAG (Yb:YAG) slabs developed by colleagues at TRUMPF Laser SE. The TRUMPF Scientific Lasers team plans to adapt the system for ytterbium glass (Yb:glass) operation. Courtesy of TRUMPF.

For this reason, the team is exploring ytterbium glass (Yb:glass), which offers a broader amplification bandwidth. Metzger sees this material solution as a potential game-changer for diode-pumped high-energy lasers, especially for future laser fusion applications.

“Lasers for fusion must be diode-pumped,” Metzger said. “We’re thinking about those components and doing simulations, but a full-scale power station would require a dedicated factory for the respective laser modules.”

State of the laser market

The trade show was huge, which reflects the state of the laser industry quite well. On one hand, lasers have matured, particularly in materials processing. The laser source itself is now largely a commodity, and machines that deliver quality that is “good enough” are sold primarily based on price. But this does not mean that the major laser manufacturers have paused innovation. On the contrary, they continue to push boundaries, using technological differentiation to stand out in an increasingly competitive field.

At the same time, lasers are moving into new applications across sectors, driving both consolidation among major players and a wave of innovation from startups. This dynamic was clearly visible in the halls of the show: Large companies with expansive booths presented industrial systems for applications such as battery welding and displays manufacturing. Smaller firms — their booths often grouped by region or theme — showcased a myriad of exciting new technologies. One entire hall was devoted to quantum technologies. Another dedicated area featured integrated photonics. Additional areas showcased medTECH, robotics (within the automatica halls), and many more applications.

But how is the market evolving overall? This is a difficult question to answer, especially in such a fragmented field.

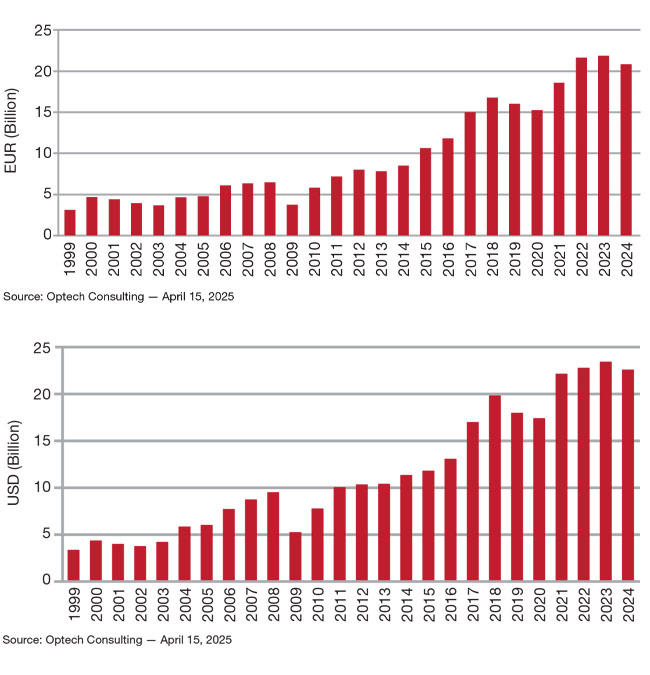

For laser materials processing, one reliable source of insight at the show is the Laser Marketplace forum. This session is a staple of each LASER Munich show, organized by Arnold Mayer, president of Optech Consulting. A seasoned market analyst, Mayer estimated the global market for laser systems in materials processing at $23 billion for 2024, a value that has decreased by 4% since 2023. However, during the past decade, the industry has maintained a healthy compound annual growth rate of 7.5%, according to Mayer. For 2025, he forecasts modest single-digit growth, driven by rising unit sales despite ongoing price erosion.

The global market for laser materials processing systems. While projections for 2025 show a decline in the global market for laser materials processing, the overall market trend for laser materials processing systems remains positive, advancing at a solid compound annual growth rate of 7% to 7.5%. This was explained by Arnold Mayer during his overview of observations and data at LASER Munich during the 17th Laser Marketplace forum. Courtesy of Optech Consulting.

To dig deeper, I had the chance to moderate a Marketplace panel with executives from three top laser firms. In my 40-min conversation with Thomas Fehn of TRUMPF, Sanjai Parthasarathi of Coherent, and Trevor Ness of IPG Photonics, several takeaways emerged:

1. Lasers are mature — especially fiber lasers. Low-cost continuous-wave fiber lasers start at $1/W, enabling applications on a mass scale.

2. Bigger is still better — high-power lasers that operate at up to 50 kW are beginning to replace plasma cutters, offering higher precision and efficiency for cutting thick materials.

3. Commoditization is accelerating — particularly due to China’s rapid adoption and intense domestic competition. But the leading players are responding with flexible, regionalized (“local-for-local”) manufacturing strategies and smart technologies.

Despite global uncertainty, one thing is clear: The laser industry is evolving rapidly. Those who adapt and innovate will be the ones shaping its future.

Industry executives Thomas Fehn of TRUMPF (second from left), Sanjai Parthasarathi of Coherent (right), and Trevor Ness of IPG Photonics (second from right) participate in a panel discussion moderated by Andreas Thoss. Courtesy of the Laser Marketplace forum at LASER Munich, Messe München.

AI is driving efficiency in laser-based manufacturing

What’s the major news takeaway from the show? I asked myself and others, and there isn’t just one. A single headline does not sufficiently capture the diversity of the technologies that were on display. But one trend clearly stood out as increasingly relevant in photonics: the application of AI.

AI is making its way into photonics in several influential ways. First, it supports complex, multiparameter problems using machine learning — for example, in optical design or the alignment of intricate laser systems, such as those used in secondary sources. Second, AI tools are already being integrated into daily production. Here, AI serves to optimize cutting trajectories, improve sorting algorithms, or even suggest ideal laser parameters via AI-driven assistants. Third, AI is now used in quality control to classify “good” and “bad” laser welds in real time based on image data.

Of the many people and companies working to bring AI into (laser) production, it is important to mention Carlo Holly, professor at RWTH Aachen University and department head at the Fraunhofer Institute for Laser Technology ILT. Holly leads several projects on AI in laser-based manufacturing and has developed a clear four-step framework for implementation. The process starts with data acquisition, using multiple sensors to monitor both the machine and the workpiece during processing. The next step is process understanding — analyzing the captured data to simulate how the process behaves. Once the simulation reliably matches real-world data, it can be used for prediction. Finally, this enables adaptive control, where the system adjusts itself, in real time, for optimal performance.

The multistep process is best illustrated with an example. Consider that some laser welding systems already record images of each weld seam. A computer, trained on thousands of labeled images, detects flaws such as spatter or pores and classifies parts accordingly. This covers steps one and two of Holly’s model. If the manufacturer can model how laser parameters affect seam quality (step three), they can begin to close the control loop, automatically adjusting laser settings to improve results (step four).

Carlo Holly, professor at RWTH Aachen University and department head at the Fraunhofer Institute for Laser Technology ILT. Courtesy of Andreas Thoss.

Holly envisions reducing the need for large training data sets using smarter learning techniques. Ultimately, this could lead to self-learning machines capable of achieving first-time-right production.

Valuable connections

It was an amazing week, full of reconnecting with old contacts and an overwhelming number of chances to make new ones. The quality of networking events has further improved. I suppose that this is due to the amazing number of breakfasts, morning runs, luncheons, and last but not least, booth parties. Thousands of drinks were handed out (standards set by TOPTICA Photonics), others got physicists dancing (HÜBNER Photonics). I enjoyed a wonderful evening at Menlo’s off-site event and connected with many people at the exhibitor reception.

Again, it is impossible to attend all these networking events. But, returning to Peter Leibinger’s words, it has never been more important to foster international exchange than it is today. LASER World of PHOTONICS was successful (by the numbers) and almost everyone with whom I spoke confirmed successful traffic at the booths and great leads to take home. I hope this quickly turns into good business. I look forward to discussing it and seeing you all again at LASER 2027!

th@thoss-media.de