Photonics HandbookIndustry News

Hyperspectral Tech of Fraunhofer Spinoff Aids Chip Production

Researchers from the Fraunhofer Institute for Material and Beam Technology IWS (Fraunhofer IWS) have established a spinoff company to commercialize a measuring system developed at the institute. Funded by the German Federal Ministry for Economic Affairs and Climate Action (BMWK), the scientists formed DIVE imaging systems GmbH to roll out a high-performance, highly flexible inspection system that features integrated hyperspectral sensor technology, artificial intelligence, and special illumination techniques.

The DIVE system uses visible light and invisible infrared thermal radiation in frequencies between 0.4 and 2.5 μm to illuminate the silicon wafers from which microchips for laptops, cellphones, cars, and more are manufactured in semiconductor fabs. The system uses a hyperspectral camera to record the reflected light.

While the human eye registers only three primary colors — red, green, blue — the hyperspectral camera distinguishes up to 1000 wavelengths of light. The high-dimensional raw data, which can quickly grow to several gigabytes, is then forwarded to an AI that can use this data to detect possible damage or contamination, as well as evaluate the quality of individual chips or the entire wafer.

The DIVE system can therefore detect, for example, whether the coating step on the wafer has been successful, and it can determine the layer’s homogeneity, thinness, evenness, or lack of defects. This ensures that only flawless wafers enter the subsequent production steps.

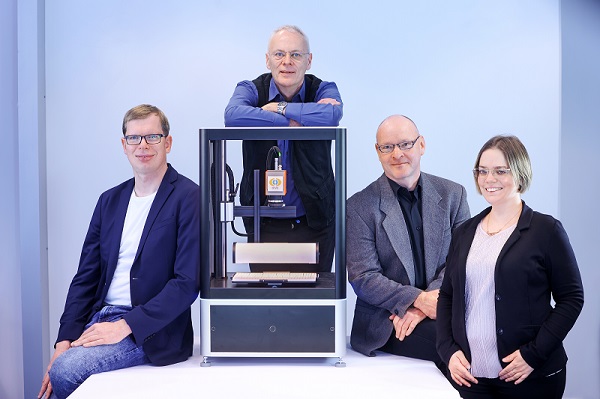

(From left) DIVE systems CEO Philipp Wollmann, with Wulf Grählert, Oliver Throl, and Livia Szathmáry, founded the BMWK-funded company to commercialize technology developed at Fraunhofer IWS. Courtesy of Amac Garbe/Fraunhofer IWS.

Together with the semiconductor manufacturer Infineon, the DIVE (short for Digital Vision Experts) team will first develop a hyperspectral system for laboratories beyond the cleanroom and, in a next step, a system suitable for use in such a laboratory. In the future, DIVE plans to develop an inline solution for direct integration into cleanroom facilities. This will allow real-time analysis of many process steps.

DIVE will manufacture the designed devices, systems, and, later, entire system components in their own production line. The spinoff is receiving 18 months of funding from BMWK, worth a total of €1.2 million ($1.3 million) as part of an EXIST research transfer program.

After the spinoff, Fraunhofer IWS will continue to develop hyperspectral technology, including concepts that use a laser to illuminate samples or drastically miniaturize hyperspectral systems. The researchers also want to use algorithms to extract significantly more information from raw data. In the future, digital twins could be created that store a variety of data in addition to traditional image and font information, such as paper thickness and type, document age, or color pigments used.

/Buyers_Guide/Fraunhofer_Institute_for_Material_and_Beam/c30990