Advancements in output, form factor, energy consumption, and beam quality are keeping a new generation of fiber laser systems on the cutting edge.

MARIE FREEBODY, CONTRIBUTING EDITOR

High-power fiber lasers are a versatile and powerful tool for a wide range of industrial applications, from cutting and welding to defense and beyond. Advancements in laser head design, beam optimization, and wavelength flexibility have caused fiber lasers to become an increasingly attractive option for manufacturers who are seeking to improve the throughput, quality, and efficiency of their production line.

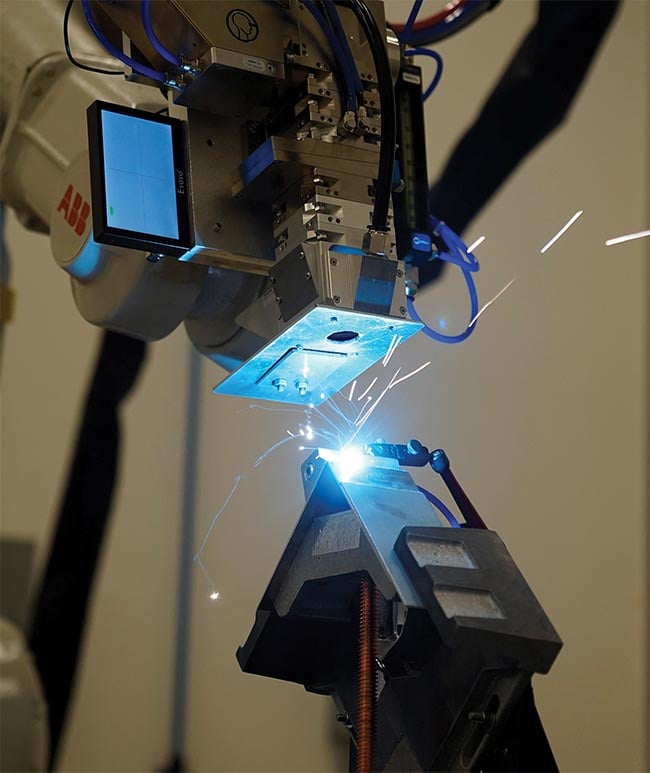

Fiber lasers can create high-quality weld seams that ensure high strength without pores, seam collapse, cracks, or end holes/divots — all qualities that are ideal for electric car battery production. Courtesy of TRUMPF.

While ever higher power systems are emerging, innovations that decrease costs and differentiate laser systems from their competitors can provide an edge to laser suppliers seeking better traction in new and existing markets.

Fiber lasers are unique in that they generate coherent light without the need for complicated or sensitive optics by pumping energy into a fiber optic cable. This yields a highly stable method of light generation. The resulting beam is generally of high quality, which means it can achieve very high output powers and focus into a very small spot size.

Laser cutting heads for ultrahigh-power laser systems must enable high duty cycles to maximize the return on investment of the instrument. This requires robust optics within the head. Courtesy of IPG Photonics.

An aluminum automotive part being welded with a 6-kW fiber laser. Sources with optimized beam shapes can often deliver excellent processing speed, improved yield, and/or higher throughput without the need to boost output power. Courtesy of nLIGHT.

Fiber lasers emitting over 1 kW are now routinely available in the industrial market. Such output is more than enough to cut through an inch of steel. But the highest power fiber lasers are found in the defense industry, where they are employed as directed energy weapons to destroy hostile targets such as missiles or drones.

Defense specialist Northrop Grumman has guided the way for building some of the highest power fiber lasers for countering threats including unmanned aerial systems, rockets, artillery, and mortar shells. The company is also currently developing its highest energy laser yet, which will be able to scale output up to

1 MW.

“Fiber lasers provide advantages due to their relatively good conversion efficiency as well as their reliability, beam quality, packaging size, and ease of integration,” said Matt Keller, Director of Directed Energy at Northrop Grumman.

Northrop Grumman’s Laser Weapon System Demonstrator recently completed deployment of the U.S. Navy’s USS Portland. The 150-kW class laser system tracks targets and employs directed energy to stop and destroy hostile drones, small craft, and other threats. It is reportedly the most powerful electric high-energy laser system ever deployed on a U.S. Navy ship.

To extend the defense applications of fiber lasers, it is important for these sources to attain higher system power to defeat more difficult threats, such as cruise and hypersonic missiles at longer ranges. One way that Northrop Grumman achieves this is by focusing on advancing fiber laser amplifiers, particularly on combining the beams from multiple amplifiers.

Scaling fiber laser power involves combining the outputs of multiple fiber amplifiers into a single beam. “This can be done in several ways,” Keller said. “Many higher power lasers built in the last decade have used spectral seam combining. More recently, coherent beam combining has emerged as a technical path to build megawatt-class fiber lasers.”

Spectral beam combining combines individual laser beams of different wavelengths via a grating, much like the reverse of separating sunlight through a prism. Scaling to higher powers is achieved by adding many wavelengths of light together.

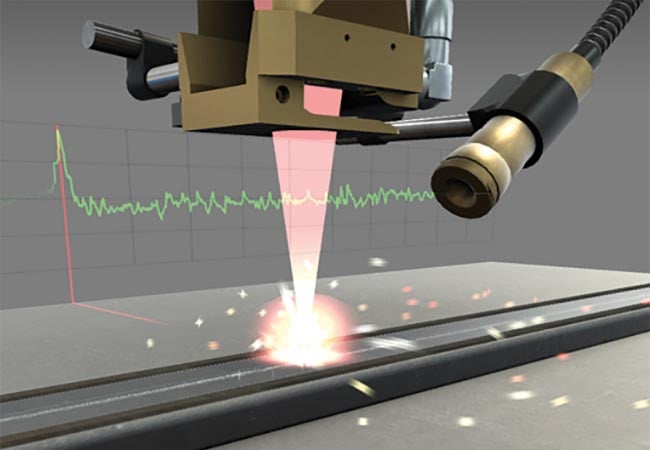

A representation of a photodiode-based process monitoring system. Real-time monitoring of laser cutting and welding ensures that processed materials meet high standards for quality and helps prevent costly defects. Courtesy of nLIGHT.

Coherent beam combining combines beams of the same wavelength by controlling each beam’s phase, resulting in a single, powerful coherent beam. Coherent beam combining systems are scaled to higher powers by simply adding additional fiber lasers and controlling their beams in the same manner.

Such advanced beam-combining techniques enable the production of 500-kW or megawatt-class lasers that extend the reach of fiber lasers to address a wider variety of security threats.

Drilling into the industrial market

Within the industrial market, fiber lasers have been successfully used in materials processing. Robert Kuba, managing director at Coherent HIGHYAG Lasertechnologie GmbH, believes that the competitiveness of high-power fiber lasers will continue to improve and, as a result, materials processing applications will see further adoption of laser tools across all power classes and types.

“Increasing laser power in laser material processing offers increased throughput and minimizes capital costs. One system today can do what two systems did yesterday,” Kuba said. “The competitive scalability of the fiber laser’s power is where we see the biggest trend in performance increase.”

For example, higher laser power can cut metal that is several millimeters thick at higher speeds. Laser cutting systems in the 6 to 30 kW power range make it possible to cut very thick metals up to and beyond 50 mm at speeds that are now enabling lasers to displace plasma cutting equipment.

“Compared with plasma cutting, the laser offers up to five times the cutting speed and increased cut accuracy with narrow kerf widths,” Kuba said. “Laser cutting heads for such ultrahigh-power machines need to enable high duty cycles to maximize ROI [return on investment]. Therefore, the robustness of the optics and the dissipation of heat loading on the head are critical.”

While many fiber laser manufacturers have been pushing their fiber laser powers above 20kW, TRUMPF has focused on improving the beam quality for its low- to mid-range sources. The company’s new TruFiber S system has beam qualities similar to its disc lasers, which result in much lower power in the beam waste.

Northrop Grumman’s Laser Weapon System Demonstrator, a 150-kW class laser installed on the U.S. Navy’s USS Portland, is designed to track and defeat hostile drones or small boats. Courtesy of Northrop Grumman.

“Excess power in the waste results in heat and stress on the optic making it difficult to cool, which can cause focal shift and cause process instability or, in the worst case, optic overheating and failure,” said Tracey Ryba, TRUMPF Inc. senior product manager for OEM Lasers in North America. “In the actual weld or cut, this is not overly concerning, but when it comes to the processing optic, this is very important.”

Cutting heads

Multiple laser suppliers are working to extend the capabilities of the high-power process heads by fielding various designs that are aimed at improving beam shape and delivery. For example, a cutting head that allows bevel cutting can increase the flexibility of the machine, while maximizing focusing conditions at the workpiece can boost the cutting performance.

Other developments include efforts to increase numerical aperture (NA) to ensure the laser head is suitable for a fiber laser system as well as other nonfiber sources. “Increasing the numerical aperture provides compatibility with a wider range of laser sources,” said Dahv Kliner, vice president of Fiber Laser Technology at nLIGHT. “It also facilities power scaling because even a small fraction of the power outside the NA limit of the head can create thermal problems as the total power is increased.”

Laser cutting systems in the 6 to 30 kW ultrahigh-power range make it possible to cut very thick metals up to and beyond 50 mm with speeds that are now displacing plasma cutting equipment. Courtesy of IPG Photonics.

Zoom heads are also used in some laser cutting tools to increase their performance and versatility by allowing the spot size on the workpiece to be adapted for different materials and thicknesses. The spot size can also be varied for different processing steps, such as switching between drilling and cutting.

“[Zoom heads] allow the end user in the job shop to cover all application cases with only one type of machine,” Kuba said. “The uptime of the machine is critical for return on investment, and zoom optics enable 24/7 operation for the processing of a wide variety of metals — such as mild steel, stainless steel, and aluminum — or for processing varying material thickness,” he added.

Another recent advancement regards scaling to high output powers, >20 kW, using transmissive optics rather than reflective optics. Reflective heads have the advantage of minimizing thermal effects on the optics and being more tolerant of contamination. However, they tend to be larger and heavier than transmissive heads. New transmissive sapphire optics from Coherent offers optical performance for lasers delivering up to 30 kW and resilience to contamination damage.

“Power scaling of transmissive heads has been enabled by advances in the quality of lenses and coatings, in thermal design, and in control of contamination,” said Kliner.

Having control of contamination is a critical concern in fiber laser design. As cutting heads are directly exposed to the process, their optics must be protected from the highly contaminated cutting environment. Specifically, sealing conditions must meet IP65 compliance, defined as the ability to withstand water projected from any direction from a distance of three meters through a 6.3-mm water-jet nozzle for a duration of at least three

minutes with pressure not exceeding

30 kPa (kilopascal).

In addition to using tight seals, another way to protect the optics within laser heads is to use a long focal length to keep the sensitive optical components far away from the process.

A further development pertains to the ability of fiber lasers to generate a tunable beam shape directly from the laser, which can provide advantages for a system’s cutting speed, edge quality, and processing window. Such advancements have enabled more versatile cutting tools to optimize performance during the processing of a wide range of materials with varying thicknesses. For example, nLIGHT’s

Corona fiber lasers provide tunable flat-top, ring-shaped, and saddle-shaped beams at powers up to 20 kW.

Tailored for e-mobility

“One of the largest growth sectors we have seen for fiber lasers in the past few years is e-mobility or battery-powered electric vehicles,” said Ryba. “For example, when compared to typical mechanical tooling, nanosecond-pulsed fiber lasers deliver much higher quality, burr-free, and extremely fast cutting of battery foil material, thus reducing scrap and manufacturing costs.”

The most important part of laser welding batteries is minimizing electrical resistance, Ryba said. “We are reducing the resistance that creates heat, which

can cause poor electrical performance and, in extreme cases, can result in the battery catching fire.”

The welding speed can be maximized while keeping deleterious effects such

as spatter and porosity to a minimum

by tailoring the beam to have a high-

intensity central spot — to create a keyhole or vapor channel in the metal — surrounded by a lower-intensity halo

to prevent closure of the top of the keyhole.

“One of the most important advances in beam shaping is the use of multicore fibers,” Ryba said. TRUMPF pioneered this technology and patented it in 2011 with the aim of using one core at a time to cut thin or thick material, or to switch from cutting to welding applications. More recent iterations of the technology enable multiple outputs on the same laser for increased performance.

Multicore fiber laser welding systems can reduce spatter between 95% and 100% compared to conventional single core fiber lasers. This can lead to stronger welds, less maintenance required to clean the tooling, and the production of higher quality parts, such as for gear assemblies.

Additional benefits include a 2 to 3× increase in welding speeds for the processing of steel, reduced porosity in aluminum, and increased weld quality in stainless steel. Spatter reduction is beneficial for e-mobility manufacturing applications as well, since a spatter ball that is stuck between two battery cells could bounce around and wear a hole in the cell walls, potentially resulting in battery failures and fires. Multicore technology also makes it possible to weld aluminum and copper tabs with the same laser.

Engineering the beam

Fiber laser specialist IPG used to derive half of its sales from cutting applications, but in the last two years they have seen the number of welding applications expand to reach record levels. Welding tools now account for close to one-third of IPG’s sales.

The company’s adjustable mode beam technology enables spatter-free welding and was introduced, in part, to target

applications in battery manufacturing. The technology offers a suitable alternative to ultrasound tools that have traditionally been used to bond copper wires to a cell terminal and bus bar.

Fiber laser supplier IPG used to derive half of its sales from laser cutting applications, but welding applications have significantly expanded in recent years to now account for close to one-third of the company’s sales. Courtesy of IPG Photonics.

Multicore fiber laser technology enables flexible distribution of the laser beam’s power between the core and the ring fibers. Courtesy of TRUMPF.

There was an evolution in the end-use applications for IPG’s lasers that began with mostly flat-sheet cutting, and progressed to include welding, medical, 3D printing, cleaning, microprocessing, solar cell manufacturing, and more recently, handheld welding, said David Fisher, senior director of Global Marketing at IPG. “There is definitely less reliance on flat-sheet cutting applications today, even though we may still continue to see growth in those applications in North America and Europe,” Fisher said.

The company recently expanded its product offering for e-mobility applications with the introduction of its quasi-continuous-wave adjustable mode beam lasers. These fiber sources occupy the space between kW-class continuous-wave fiber lasers and Q-switched pulsed lasers by producing peak pulse powers that, compared to continuous-wave mode,

deliver 10× more energy at pulse durations between 10 µs and 100 ms. This enables its suitability for high-precision welding, fine cutting, and drilling applications for which their high pulse energies can initiate or sustain laser-material coupling while avoiding the cumulative

heat produced by continuous-wave sources.

Driving the future of fiber lasers

The effect that fiber lasers have had in materials processing applications has propelled their success and growth and ensured that these sources will continue to inspire new innovations and rigorous competition from many suppliers.

Examples include the emergence of

advanced process sensors in a bid to monitor and maximize yield and part quality. Real-time monitoring of laser cutting and weld quality ensures that high standards are met, which helps prevent costly

defects. Other advancements aim to reduce downtime or service costs by enabling servicing at the tool, which is a particular challenge in harsh environments.

“Fiber lasers will continue to grow in popularity in coming years,” TRUMPF’s Ryba said. “They offer significant process benefits within a small footprint, have low energy consumption and low maintenance needs, and with higher powers coming out, they are cost-effective replacements for traditional plasma and mechanical processes.”

Suppliers are keen to stress that the up-front cost of a laser system is not the only metric to bear in mind when choosing any tool. The cost of associated subsystems, operating costs, and any maintenance or downtime are also factors that will affect the bottom line.

Fiber lasers with optimized and tunable beam shapes allow the processing speed, yield, and/or throughput to increase without the need to boost output power.

“For some tools, a lower laser power can be used, which decreases both up-front and operating costs and reduces downtime associated with servicing of the high-power laser optics,” nLIGHT’s Kliner said. “The tool can be more versatile, increasing tool utilization by supporting a wider range of jobs, and even reducing the number of tools that have to be supported in a given shop or production line. Although fiber lasers have been the highest growth segment of the laser market for many years, suppliers still

see many opportunities for continued innovation.”