Industrial femtosecond lasers deliver the performance and versatility for the precise processing of materials supporting various industrial fields.

SIMAS BUTKUS, DOMAS BALIUKONIS, AND MARCO ARRIGONI, LIGHT CONVERSION

The physical parameters and versatility of femtosecond sources help to facilitate operations that are beyond the reach of more conventional laser technologies. As emitters of high-intensity, ultrashort-pulse (USP) radiation, the current class of femtosecond lasers is essential to materials micromachining — and these lasers enable precision fabrication that supports applications across industries ranging from aerospace and defense to finance.

Courtesy of iStock.com/Christian Bay

While these lasers can be built in fiber or free space (solid-state media), free-space femtosecond lasers outperform their counterparts due to their superior pulse quality, characterized by the absence of background radiation that is present in fiber-based systems. Also, the burst mode capability of contemporary femtosecond lasers allows a single USP to be divided into a series of pulses separated by hundreds of picoseconds to tens of nanoseconds. This mode significantly enhances ablation efficiency, improves overall materials processing quality, and delivers a distinctive surface finish.

From research to commerce

Almost everyone owns an electronic device containing components processed with a femtosecond laser, from a smartphone to a flat-panel display. Many of us have even been “processed” by a femtosecond laser ourselves: Ophthalmic procedures commonly use these lasers, and femtosecond lasers also find use with stents and other medical devices that must be cut or scribed in some way.

Although the use of femtosecond lasers for these purposes is currently commonplace, femtosecond processing was an upcoming technology at the start of the century. The first reports of material ablation using femtosecond pulses date to 1987. In an initial demonstration of polymethylmethacrylate (PMMA) ablation, scientists used an excimer laser at 248 nm — significantly different from the tools that currently drive the realization of femtosecond materials processing. In the 1987 report, the study authors found two key advantages of femtosecond pulse processing: “cold” ablation, which resulted in a minimal heat-affected zone, and the multiphoton absorption process, which circumvents the wavelength requirements that are typical of linear absorption.

This seminal demonstration occurred two years after Gérard Mourou and Donna Strickland invented chirped pulse amplification (CPA). Before the development of this energy-scaling technology, femtosecond pulse energies were limited to sub-microjoule levels due to peak power-dependent nonlinear processes that could damage the laser medium during the optical amplification process. CPA, with its stretch-amplify-recompress

approach, scaled the energy of femtosecond pulses to hundreds of millijoules or more, making femtosecond materials processing practically feasible.

By 2000, femtosecond processing applications were developing, though at a slow rate. These applications were based on titanium sapphire (Ti:Sapphire) amplifiers, which were expensive and complex platforms, and which required a continuous-wave laser and a nanosecond laser to pump the femtosecond laser and amplifier, respectively. Most Ti:Sapphire amplifiers excel at producing 5- to 10-mJ pulses at a 1-kHz repetition rate — a clear mismatch with materials processing

applications that require much higher average power and rely on high pulse repetition rates to achieve high industrial throughput.

The mid-2000s marked the advent of lasers based on a new active media, specifically ytterbium (Yb)-based laser amplifiers, which quickly became

available in a variety of formats, including fiber, bulk crystal (solid-state free-space), and thin disk. In each format,

the superior flexibility and scalability of the Yb platforms enabled systems to deliver average powers reaching tens of watts at up to megahertz repetition rates. The longer pulses of Yb-based systems (200 to 400 fs) compared with Ti:Sapphire amplifiers (50 to 100 fs) were not a limitation. Rather, they simplified dispersion management during propagation because optical materials dispersion affects longer pulses less profoundly than shorter ones. Today, nearly every industrial USP laser is based on a Yb-active medium.

Pulse cleanliness

It is generally accepted that a pulse is considered “clean” if most of the energy is stored within a few hundred femtoseconds and no residual background photons are present outside this time frame. Yet, this property of femtosecond pulses often lacks proper, comprehensive consideration, and few measurements quantify this effect.

This is not a trivial factor to overlook; a typical autocorrelator, for example, may not detect the background. And, the power level, as measured with a conventional power meter, will show as adequate regardless of pulse cleanliness. In fact, it is only possible to detect the background when using alternative pulse measurement techniques, such as a third-order nonlinear autocorrelator.

This is not the only common oversight influencing perceptions of pulse cleanliness as it relates to materials processing. Typically, a femtosecond laser system consists of an oscillator and an amplifier, and the importance of the oscillator is often unmentioned in the realm of materials processing. Indeed, the implementation of this technology can have a

considerable influence on the results.

Although almost all femtosecond laser oscillators are Yb-based, there are differences in the technology and, specifically, in how it is implemented for a system.

Two approaches are used most often:

fiber-based oscillators and solid-state free-space oscillators. Although fiber-based technology is considered the simpler and cheaper approach, there are nuances to consider prior to their use.

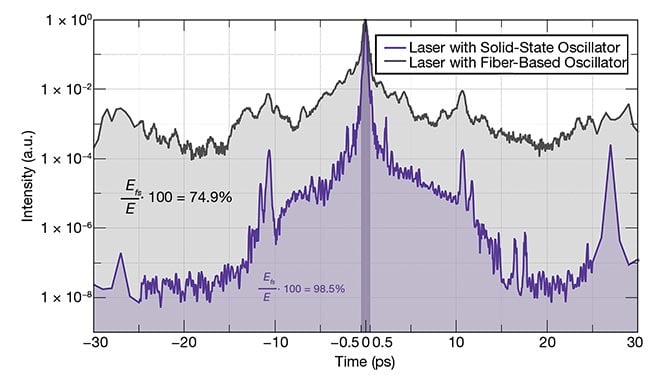

Figure 1. Pulse contrast ratio measurements comparing Light Conversion’s CARBIDE femtosecond laser with a solid-state oscillator to a laser with a fiber-based oscillator. Approximately 25% of the power stored in the femtosecond time frame is lost in the case of fiber-based technology. Courtesy of Light Conversion.

Figure 1 shows these discrepancies as well as typical contrast measurements. The first measurement reflects a femtosecond laser after amplification and compression within a 60-ps timescale around the main 300-fs pulse. This measurement was conducted by integrating the intensity in this time frame:

The measurement was conducted using a Light Conversion CARBIDE series femtosecond laser and a commercially available third-order nonlinear autocorrelator.

In this sequence, >98% of the photons are concentrated within a 1-ps range around the main femtosecond pulse. This indicates that the system generates femtosecond pulses with minimal trailing or leading photons. The background radiation does not significantly contribute to the overall power measurement in this case, as it decreases from a level of 10−4 below to 10−7, relative to the main pulse within the measured range. From this figure, it is evident that such a system can produce clean pulses, achieving high peak intensity.

Figure 1 also shows a measurement performed with the same setup on a fiber-based laser. The number of photons within the same (1-ps range around the 300-fs pulse) accounts for only ~75% of the total photons within the 60-ps range.

The presence of spontaneous emission in fiber-based technology is the main contributor to the difference between the two systems. Though at first glance this variation may not seem significant in terms of influencing system performance, it can have a strong effect in processing materials. The background radiation may result in a higher damage threshold for many materials and can lead to additional unwanted sample heating. The measured damage threshold for a specific material can be >1.3× lower when comparing a laser with a good temporal contrast to

a poor temporal contrast laser source,

because the low-intensity background does not contribute to the damage. Ultimately, in this case, ~25% of the average power of the fiber-based laser source

does not contribute to the processing of the material.

Even in cases of bulk material(s) processing, temporal pulse cleanliness plays a role in transparent materials, such as glass. A less optimal pulse shape results in energy in its plateau being transmitted through the material, which inhibits its usability for the nonlinear absorption process. Consequently, more power is required to produce modifications inside the bulk of transparent materials using fiber-based USP lasers1. A recent use case investigating laser writing in silica glass demonstrated the favorable pulse temporal contrast of a free-space Yb-based laser, which in turn offers multiple benefits compared to fiber laser systems for the same purpose1.

In response to this limitation, a typical commercial laser source from Light

Conversion combines a Yb-based solid-state free-space oscillator with a regenerative amplifier. The solid-state oscillator generates femtosecond pulse trains with high temporal contrast, resulting in clean pulses after amplification, ensuring

sustained performance for the most intricate industrial applications.

Ablation efficiency

Ablation efficiency has been extensively studied across various materials and laser sources. These sources include fiber- and free-space-based systems. These investigations prove that comparing degrees of ablation efficiency highlights the importance of the pulse cleanliness effect on materials processing.

There are distinct differences in

ablation efficiency values between

fiber-based technology and free-space-based systems. When considering the ablation efficiency of copper, for example, for a single pulse (non-burst mode), the material removal rate for a fiber-based system2-4 is 0.2 mm3/minW, whereas the removal rate for a free-space system5 is 0.3 mm3/minW. While pulse cleanliness

is not single-handedly responsible for such large differences (approaching 50%) the effect nevertheless plays a significant role in the ablation process. Background radiation, which does not cause ablation,

mainly results in the heating of the

peripheral regions, or is reflected from

the surface of the sample.

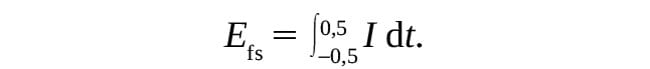

Figure 2 shows a typical ablation

efficiency graph for various widely used metals, in a sequence using a USP source. With the pulse fluences just above the ablation threshold, the ablation efficiency is low, shown by the curve. This occurs because only the top part of the Gaussian beam contributes to ablation, while the wings mainly contribute to the heating of the material(s). In this case, the amount of removed material mass, or volume per unit of average power, is low.

Figure 2. A typical ablation efficiency diagram of metals using ultrashort-pulse (USP) laser technology, depicting energy-specific volume for single-pulse laser ablation 6. With the pulse fluences just above the ablation threshold, the ablation efficiency is low, as shown by the curve. The ablation efficiency is also low even at high fluences, since a significant portion of the pulse energy is converted into thermal energy in the ablated mass. Courtesy of D.J. Förster et al. (www.doi.org/10.3390/ma14123331).

After reaching a peak, the ablation

efficiency decreases at very high fluences. This is because a significant portion of the pulse energy is wasted in the form of kinetic or thermal energy in the ablated

mass, which itself results because the penetration depth of light does not

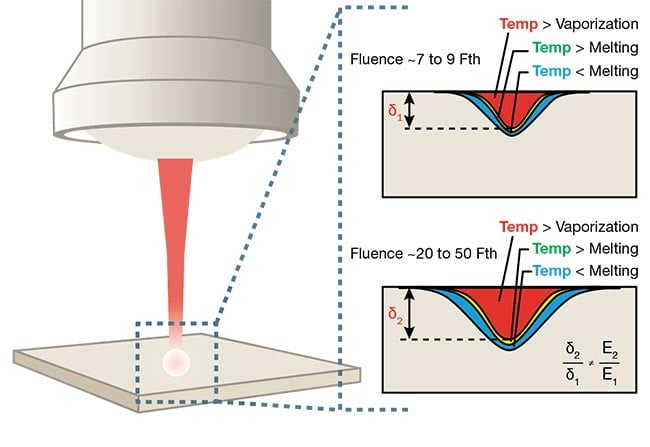

increase linearly with the fluence (Figure 3). However, if the fluence is set to ~7

to 9× the damage threshold, the ablation

efficiency is at its highest. There are various explanations for this behavior, which are attributed to different ablation mechanisms6. These include spallation

or fragmentation of the exposed area without overheating as well as material ejection at moderate velocities and lower temperatures. In these cases, most of

the average power is used for ablation and not wasted as heat and kinetic energy.

Figure 3. A demonstration of energy penetration into a material at different fluence levels. The higher fluence results in a mild increase in the total ablated mass. Temp: temperature. Courtesy of Light Conversion.

Burst pulses

The ablation efficiency values in Figures 2-3 demonstrate how it is typically necessary to set the fluence value to <10 J/cm2 for most materials. However, this poses a problem: In recent years, as USP laser average powers have reached 100 W and above, it has become complicated to harness the full power of the laser for use and maintain optimal ablation settings. For a 100-W laser source, for example, it may be practically difficult to maintain a fluence setting of <10 J/cm2. Additionally, operating at this regime would require the laser to function in the megahertz repetition rate range, which could introduce additional unwanted heating effects, such as pitting of the ablated surface, melt formation, burr formation, metallic phase change, and/or chemical degradation.

The so-called burst mode addresses these issues by splitting the pulse energy of a single conventional pulse into a

train of femtosecond pulses, temporally separated by tens of nanoseconds

(megahertz burst) or hundreds of picoseconds (gigahertz burst).

In a burst mode, the pulse separation is such that transient material properties become relevant insofar as they may now affect the entire process. For example,

the pulse spacing may be so short that

locally generated heat does not have

sufficient time to diffuse in the material,

and the hot mass would be more efficiently ablated out of the surface by the trailing pulses. Moreover, it is easier to maintain the fluence of each intra-burst

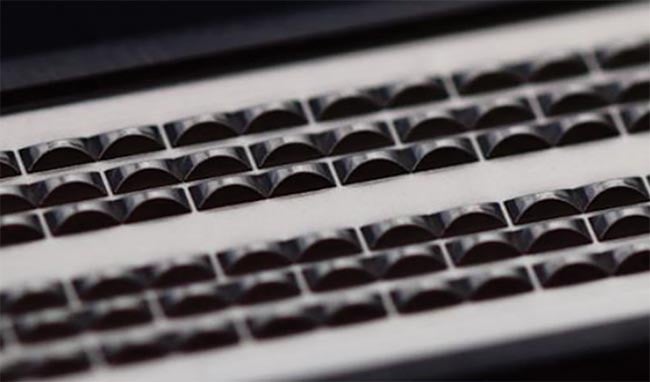

pulse closer to the ideal fluence for maximum efficiency. Heat input into the material can be controlled by tailoring the burst configuration — the number and energy of each pulse — to create unique surface features, such as viewing-angle-independent white markings, polishing an ultrafine layer of the ablated surface, or unique surface texturing. Figure 4 shows typical burst mode applications in multiple contexts.

Figure 4. A demonstration of ultrashort-pulse (USP) laser processing shows cutting and welding of microscopic watch parts from brass (top) and an ablation of 3D shapes and surface texturing. Courtesy of Light Conversion.

Final thoughts

Tracing the evolution of femtosecond processing to current-generation laser platforms, based almost exclusively on Yb media, requires the consideration of process parameters as well as the exploitation of increased powers and pulse energies. This article highlights the relevance of clean pulse shape, providing examples in both opaque and transparent materials. Finally, configurable burst-mode operation fully exploits the increased average power and pulse energy available from current-generation lasers.

Often, “the devil is in the details” when it comes to picking the right laser and optimizing the parameters for a specific material and process. There is no substitute for in-house expertise both in laser design and application development.

Meet the authors

Simas Butkus is head of the Applications Laboratory at Light Conversion, specializing

in femtosecond micromachining, laser light-matter interaction, and beam propagation effects; email: [email protected].

Domas Baliukonis is a product manager at Light Conversion, overseeing the development of the company’s femtosecond lasers; email: [email protected].

Marco Arrigoni, vice president of marketing at Light Conversion, has more than 30 years

of experience in market development for

ultrafast lasers; email: [email protected].

References

1. Y. Lei et al. (2024). Controlling ultrafast laser writing in silica glass by pulse

temporal contrast. Opt Lett, Vol. 49, No. 9, pp. 2385-2388.

2. J. Lopez et al. (2015). Ablation efficiency

of high average power ultrafast laser.

J Laser Appl, Vol. 27, No. S28008.

3. J. Lopez et al. (October 1, 2013). Parameters of influence in surface ablation of metals with using a high power tunable ultrafast laser. Proc International Congress on

Applications of Lasers & Electro-Optics,

pp. 686-694.

4. G. Bonamis et al. (2019). High efficiency femtosecond laser ablation with gigahertz level bursts. J Laser Appl, Vol. 31,

No. 22205.

5. A. Žemaitis et al. (2021). Femtosecond laser ablation by bibursts in the MHz and GHz pulse repetition rates. Optics Express,

Vol. 29, No. 5, pp. 7641-7653.

6. D.J. Förster et al. (2021). Review on

Experimental and Theoretical Investigations of Ultra-Short Pulsed Laser Ablation of Metals with Burst Pulses. Materials,

Vol. 14, No. 12, p. 3331.