Single-crystal diamonds enable Raman lasers to achieve higher gain, greater power densities, and changeable wavelengths.

GRANT J. VARNAU AND HENK DE WIT, ELEMENT SIX TECHNOLOGIES

Ever since Ted Maiman used a flash-pumped synthetic ruby crystal to generate the first coherent light source in 1960, the development of optical gain media has become a critical area of study for many science and engineering fields. While traditional approaches have generated coherent light by incurring a population inversion within the lasing media, more creative methods, such as Raman lasing, have since emerged to permit the tuning of laser light, specifically at high power densities.

Ever since Ted Maiman used a flash-pumped synthetic ruby crystal to generate the first coherent light source in 1960, the development of optical gain media has become a critical area of study for many science and engineering fields. While traditional approaches have generated coherent light by incurring a population inversion within the lasing media, more creative methods, such as Raman lasing, have since emerged to permit the tuning of laser light, specifically at high power densities.

Diamond

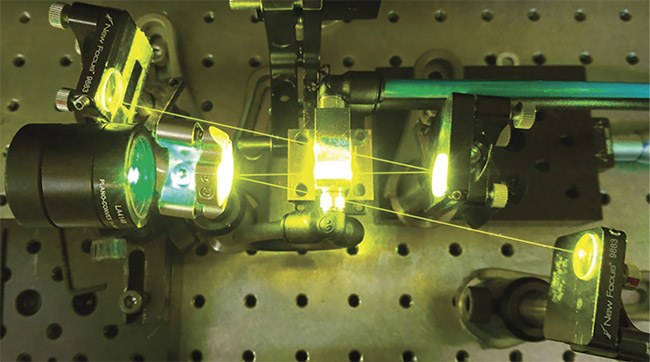

Raman crystals pumped by 532 nm to produce 573-nm first-order Stokes. Courtesy

of Ondrej Kitzler, Macquarie University.

Raman lasers leverage the principles of stimulated Raman scattering to shift the light that comes into the gain medium by a frequency corresponding to the vibrational frequency of the material. Pumping Raman crystal cavities at very high power densities enables frequency conversion, cascading, and amplification because the gain of a Raman laser is dependent on the pump intensity and the gain coefficient of the Raman crystal material.

The lattice structure of the gain medium is very pertinent to Raman lasing

because it dictates the available vibrational modes and absorption. Lattice structure is also important to achieving the M2 cleanup effect, whereby pumping of a crystal with a low-spatial-quality beam produces a more defined beam with higher spatial quality1.

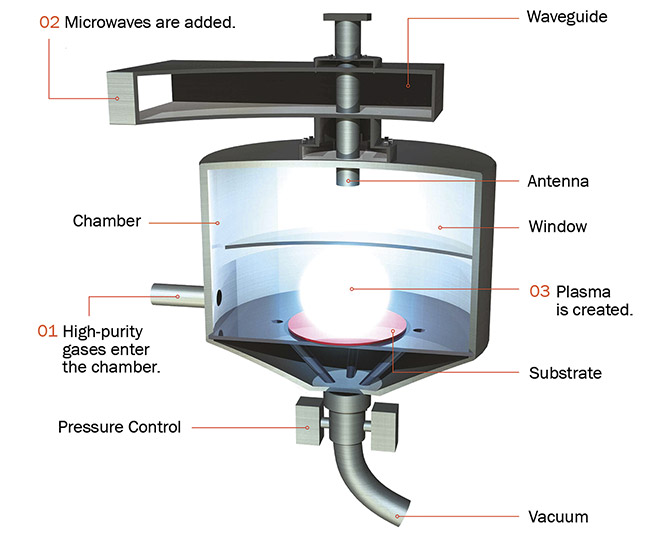

A schematic of a microwave plasma-assisted CVD diamond deposition chamber, in which atomic hydrogen is generated through the coupling of a high-power microwave source into a thermal plasma. Courtesy of Element Six Technologies.

These factors make single-crystal diamond an ideal candidate for Raman lasing due to the material’s rigid lattice, low absorption, and high thermal conductivity. Diamond Raman lasers utilize diamond’s Raman shift of 1332.3 cm−1, the highest of any material, to generate new wavelengths at ultrahigh power densities. Wavelength conversion efficiencies have been reported upward of 30% at kilowatt-class power levels in the visible (~600 nm) and near megawatt (MW)-class power levels in the near-IR (1.5 µm)2. All of this is possible due to recent progress in high-purity and crystal-quality diamond growing methods.

Diamond growth and processing

Optical quality diamond is achieved through microwave plasma-enhanced chemical vapor deposition (CVD). This homoepitaxial growth process utilizes a vacuum chamber in which a substrate is preseeded with single-crystal CVD diamond plates oriented for the  100

100 growth direction. The substrate is then exposed to a high-energy plasma of ultrahigh-purity carbon-bearing gases diluted with hydrogen. These gases tend to be hydrocarbons, most commonly higher-purity methane due to its availability. The combination of these carbon-bearing gases with atomic hydrogen is essential for diamond growth, though the reaction can be further assisted with small additions of oxygen and noble gases.

growth direction. The substrate is then exposed to a high-energy plasma of ultrahigh-purity carbon-bearing gases diluted with hydrogen. These gases tend to be hydrocarbons, most commonly higher-purity methane due to its availability. The combination of these carbon-bearing gases with atomic hydrogen is essential for diamond growth, though the reaction can be further assisted with small additions of oxygen and noble gases.

Comparison of Material Properties for Raman Crystals

g = Raman gain coefficient; Δλ = spectral resolution; k = thermal conductivity; L = typical crystal length;

dn/dT = refractive index as a function of temperature; FoM = thermoelectric figure of merit

With thermal conductivity three orders of magnitude higher than barium nitrate, diamond's thermal lensing effects are almost negligible.

In gas-flow recipes designed to efficiently deposit diamond, the critical parameter is the molar ratio of carbon-bearing gas flow to atomic hydrogen that is achieved by thermal dissociation of H2 gas in the plasma. The typical temperature of the plasma is 2000 to 3000 °C. During deposition, a substrate temperature in the range of 550 to 1200 °C is critical for high-quality CVD diamond growth.

Once synthesized, the new CVD diamond single crystals represent only part of the manufacturing process. Individual crystals are laser-cut from the substrate, then lapped and polished to meet desired specifications. Research shows that the  110

110 direction in diamond generates the most Raman gain, and therefore a process of rough lap, fine lap, and polish on the facets of this direction is ideal. There have been cases where the diamond could be cut and polished to generate light in the

direction in diamond generates the most Raman gain, and therefore a process of rough lap, fine lap, and polish on the facets of this direction is ideal. There have been cases where the diamond could be cut and polished to generate light in the  110

110 direction but polarized along the

direction but polarized along the  111

111 plane. While difficult, this is achievable and even desirable for certain Raman lasing systems. Through these various techniques and processes, uniquely engineered and refined Raman crystals can be formed with high dimensional tolerances and specifications, including:

plane. While difficult, this is achievable and even desirable for certain Raman lasing systems. Through these various techniques and processes, uniquely engineered and refined Raman crystals can be formed with high dimensional tolerances and specifications, including:

-

xyz tolerances up to 7 × 7 × 2 mm ±50 µm.

-

Polished surfaces up to Ra <5 nm.

-

Parallelism: <1 µm/mm.

-

Birefringence: Δn <5 × 10−5 along

110

110 .

.

-

Absorption: <0.005 cm−1 at 1064 nm.

Diamonds extend performance

CW and pulsed lasers come in various forms, sizes, power outputs, cavity configurations, and more, but they are often limited in their ability to produce new wavelengths. Often the emission wavelength of a laser is determined by the gain medium being pumped, and the tuning of that medium is typically limited by the electronic transitions it allows. Diamond Raman lasers offer unique options for optimizing CW and pulsed lasers, due to diamond’s ability to offer the largest Raman shift of any material, a very high laser-damage threshold, and high thermal conductivity.

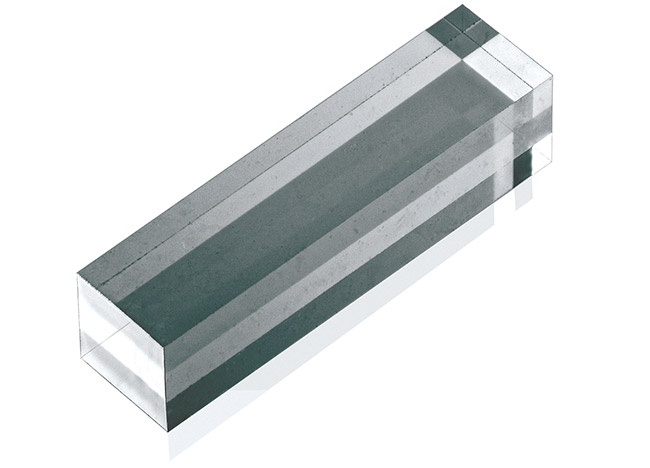

CVD diamond Raman crystal after processing. Courtesy of Element Six Technologies.

Diamond Raman lasers can change output wavelength by utilizing diamond’s Stokes shift, which is the difference in frequency between an incoming photon and the lower-energy photon scattered by the material. This feature of Raman lasers also allows wavelengths to be cascaded, meaning that pumping into the first Stokes wavelength will produce second and third Stokes wavelengths, depending on how the Raman laser cavity is configured. This results in the ability to selectively tune laser output based on the available Stokes shifts from the pumping frequency and cascaded Stokes wavelengths.

All of these wavelengths are produced at higher conversion efficiencies in comparison to those generated through traditional optical parametric frequency-conversion devices based on nonlinear crystals such as β-barium borate (BBO) and potassium dihydrogen phosphate (KDP). Such devices rely on sum- or difference-frequency generation mixed with broadband white light to generate new wavelengths. The nature of parametric frequency generation makes it wavelength sensitive, which means conversion efficiencies can vary greatly across the visible to IR spectrum. The process is also very difficult to achieve efficiently at high power densities due to nonlinear and parasitic absorption phenomena that generate higher losses. It should be noted that Raman crystals can be coupled with nonlinear crystals such as BBO and KDP in various configurations to generate a broad range of wavelengths.

Diamond’s Raman shift of 1332.3 cm−1 translates to a change in wavelength when pumped at 532 to 573 nm, or when pumped at 1064 to 1240 nm for the first Stokes wavelengths. Other Raman crystals such as potassium-gadolinium tungstate (KGW) and barium nitrate (Ba(NO3)2) exhibit Raman shifts of 901 and 1048 cm−1, respectively. Diamond offers many advantages over these other Raman crystals, as described in the table above (Comparison of Material Properties for Raman Crystals).

Raman lasing utilizes the vibrational frequency of the crystal lattice, which makes heat dissipation through the lattice a critical parameter because it can limit laser output. When any optical material reaches too high a temperature, thermal lensing effects can ruin the ability to control beam profile. With thermal conductivity three orders of magnitude higher than barium nitrate, diamond’s thermal lensing effects are almost negligible.

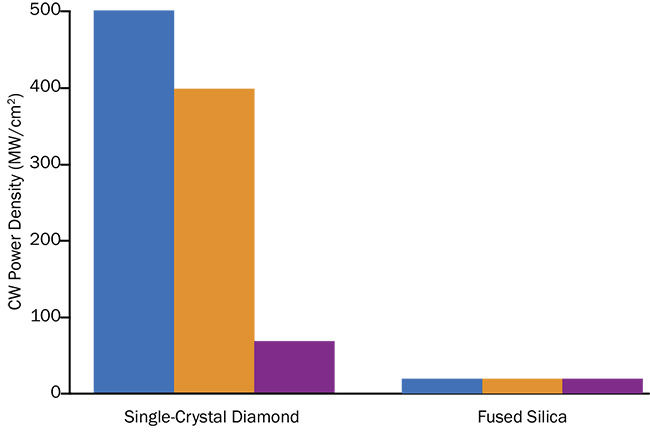

Research by Element Six Technologies demonstrates that three windows fabricated from single-crystal diamond exhibit a significantly higher laser-induced damage threshold during CW operation at 1070 nm than windows made from fused silica. Courtesy of Element Six Technologies.

Diamond is also chemically inert and high in mechanical strength with a Young’s modulus over 1000 GPa. Barium nitrate, in contrast, is soft and hygroscopic.

Used as a gain media, KGW has a wider transmission window versus diamond, but the latter offers one to two orders of magnitude higher gain — the highest gain in the visible spectrum, reaching values near 100 cm/GW when pumped at 266 nm.

Due to the thermal and optical properties of diamond, Raman lasers enable higher pulse energies and power densities. Researchers have demonstrated that single-crystal diamond exhibits a significantly higher laser-induced damage threshold (LIDT) than fused silica in CW operation3. Although the research disclosed a wide range in damage tolerance for diamond, the material’s worst performance results were nearly two times more resistant to LIDT than fused silica. This suggests that, regardless of the application, diamond’s exceptional material properties can help achieve higher power densities for Raman lasing.

Although Raman lasers are a well-established technology, they have yet to be adopted as widely as diode-pumped solid-state (DPSS) or fiber lasers. This is partly due to the limited power densities available from nondiamond Raman crystals, and other factors within typical operating environments. Diamond Raman crystals, however, have the potential to solve these issues by offering increased gain, higher power density, and material strength. Applications such as 3D metal printing, laser welding of plastics, lidar, and directed energy all require higher power densities than previously seen, as well as new wavelengths and higher spatial beam quality. Diamond Raman crystals not only offer unique solutions that could unlock such applications, the crystals may also help to extend the applications’ boundaries.

Meet the authors

Grant J. Varnau is applications engineer at Element Six Technologies and develops CVD diamond products for high-performance optical and thermal applications.

Henk de Wit is business manager of CVD diamond optics at Element Six Technologies.

References

1. S. Antipov et al. (2019). 1.2 kW quasi-steady-state diamond Raman laser pumped by an M2 = 15 beam. Opt Lett, Vol. 44, pp. 2506-2509.

2. R.J. Williams et al. (2018). High power diamond Raman lasers. IEEE J Sel Top Quantum Electron, Vol. 24, No. 5, pp. 1-14, Article No. 1602214.

3. E. Anoikin et al. (2015). Diamond optical components for high-power and high-energy laser applications. Proc SPIE, Vol. 9346, Components and Packaging for Laser Systems, Article No. 93460T.