KEN BARAT, LASER SAFETY SOLUTIONS

Among the broad range of technologies that are governed by standards, Class 4 laser systems face a familiar hurdle. While technology standards aim to build parameters for safety, access, and performance, they often struggle to keep pace with the advancements that improve and add value to the technologies that they are ultimately designed to help regulate and streamline for use.

Those who are familiar with the American National Standards Institute (ANSI) Z136 series of laser standards know that the use of Class 4 laser systems requires some level of access control. For those who are unfamiliar, ANSI Z136.1, Safe Use of Lasers, is considered the acceptable road map for laser user safety guidance. The Z136 series has expanded to several application-based vertical standards to address more specific laser safety guidance, such as medical, outdoor, and research.

In the past, the effects of standardization (engineering and administrative controls) were considered absolute. Indeed, certain facets of standards — for example, laser safety officer (LSO) appointment, training, and laser controls areas — remain firmly locked in place.

But much like the way that “Star Trek” producers rework the history of their science fiction adventures, standards are also subject to change. Z136 laser use standards are principally geared toward traditional laser systems, and, with new editions of these standards taking nearly seven years to generate, they often lack responsiveness to changes in laser technology and applications. This discrepancy is critical, especially when considering access control, and especially when regulatory bodies, such as OSHA, look to the Z136 standard as their measuring metric for laser safety.

Access control

As the parent document of the Z136 series of laser safety standards, Z136.1, Safe Use of Lasers-2021, gives the Class 4 laser user three broad options for access control: undefeatable, defeatable, and administrative. These standards cover entryway safety controls designed to always allow unobstructed egress by laser personnel and admittance to the laser control area (LCA) under emergency conditions. Z136.1 further states that all Class 4 LCAs shall incorporate one of the following sets of regulations:

a) Undefeatable Area or Entryway Safety Controls

Undefeatable safety latches and area interlocks deactivate the laser or reduce the output to safe levels in the event of unexpected entry into the LCA. Examples include electrical switches, pressure-sensitive floor mats, and infrared and sonic detectors.

b) Defeatable Area or Entryway Safety Controls

Defeatable safety latches and area interlocks shall be used if undefeatable area or entryway safety controls limit the intended use of the laser or laser system. During normal usage requiring operation without interruption, these controls may be used if it is clear that there is no laser radiation hazard at the point of entry. In this case, overriding the safety controls shall be permitted to allow access to authorized personnel if they have been trained and provided with adequate personal protective equipment (PPE). This may be the case for long-term testing or medical procedures.

c) Procedural Area or Entryway Safety Controls

Where safety latches or interlocks are not feasible, for example, during some medical procedures or service procedures, the following shall apply:

1) All authorized personnel shall be adequately trained and provided adequate PPE prior to or upon entry.

2) A door, blocking barrier, screen, or curtains shall be used to block, screen, or attenuate the laser radiation at the entryway. The level of laser radiation at the exterior of these devices shall not exceed dangerous levels, nor shall personnel experience any contact with radiation above the maximum permissible exposure immediately upon entry.

Enduring challenges

Complicating the aforementioned implementations is the expansion of hand-held Class 4 laser systems, which can leave some users of laser welders and/or rust removal systems, for example, in an uncertain position. These hand-held devices can produce hundreds to thousands of watts of open beam paths, establishing themselves as Class 4 lasers, but they often operate with little to no access controls. Rust removal devices can be rolled across floors while some can be carried on the back of a user. Laser welders, while having very limited beam paths, also fall under these laser standards and require access controls in their work area.

Further, laser fingerprint detectors, such as those used by forensics teams at crime scenes, also fall under these standards, but challenge the ability to establish required controls governing user access. These examples demonstrate the expanded application of Class 3B and Class 4 laser systems beyond their original applications and their envisioned environments, presenting challenges to meeting safety standards.

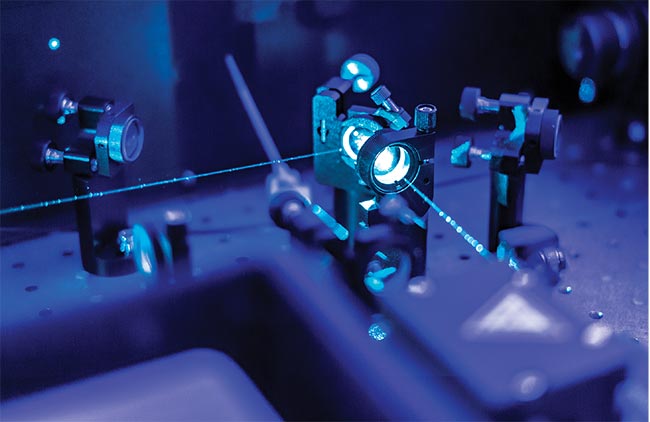

As the technology around

Class 4 lasers continues

to advance, so must the

standards and regulations

designed to keep users

safe. While Z136.1 offers

an improved set of safety

measures, more is needed. Courtesy of iStock.com/M?xa?? Py?ehko.

In addition, a new type of access control must now be considered, as many groups operate Class 4 lasers from offsite locations. Many — including myself — define these operations as those occurring in which users can make changes to systems remotely. These changes may include opening or closing shutters or inserting optics with motorized mounts from a distant location. While this is a great convenience to those users, it presents new challenges and potential dangers. A core challenge that I have observed, and one that faces many facilities, is the failure to address occupancy in LCAs when a remote user accesses the system. Offsite use inherently complicates the job of the LSO, who must evaluate risk to anyone in the LCA. The possibility that remote workers could inadvertently expose others to open beams, or that users in the LCA could open an enclosure without knowing that a beam is accessible, must be kept top of mind.

To keep up with evolving technology, laser standards and safety officers must consider how to protect all parties when a facility uses remote access. They must also consider what type of access control, if any, is needed for those mobile Class 4 laser products.

As the LSO looks to provide laser safety through access control, several options should be considered, and interlocks are a common solution. From an administrative perspective, barriers, key cards, and electronic locks that control access but do not disturb laser operations could be a solution. For open use applications, a safety watch, barriers, and awareness training for general staff can all contribute to laser safety. As for remote users, indicator lights displaying remote access status and other procedures to confirm remote operation or room occupancy must be developed. Technology will keep advancing and standards and LSOs must be aware of new challenges and controls to keep workers safe.