Steve Zhu, Teledyne DALSA

Instant noodles, a global staple, are consumed at a rate of more than 100 billion servings annually, and there was a 10% surge in demand for them during the pandemic alone. Major producers in countries such as China, Japan, Korea, and Taiwan supply a wide variety of instant noodle brands with diverse flavors, catering to millions of consumers. Given the high demand and tight production timelines, maintaining consistent quality is critical to satisfy the market. Manufacturers must ensure that each batch meets the desired standards for texture, appearance, and taste, and that machine vision cameras can detect defects in instant noodles in mere milliseconds.

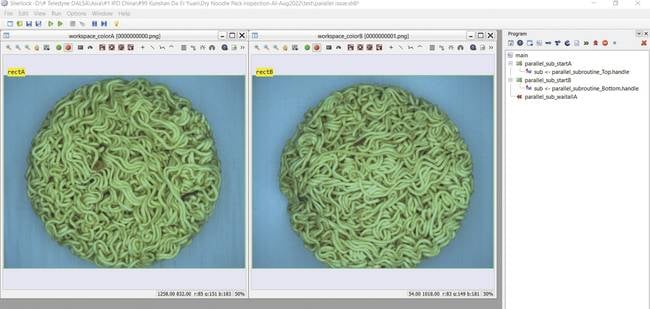

Software analysis can compare data from numerous images quickly and effectively. Courtesy of Teledyne DALSA.

Traditional quality control methods, often dependent on selective human inspection, are no longer sufficient to meet the scale and speed of modern production lines. To address these challenges, the instant noodle industry has turned to advanced machine vision technology for automated, real-time defect detection. Manufacturers have learned how an industrial AI-integrated inspection system can enhance the quality control process in instant noodle production, ensuring that defects such as overcooked starch, debris, grease, and large holes are identified with near-perfect accuracy.

The inspection process

The instant noodle production process involves multiple stages, including mixing flour and water to create dough, starching, frying, steaming, and drying the noodles. During these stages, defects can emerge, such as:

AI systems can detect any impurities or defects more quickly than human personnel can. Courtesy of Teledyne DALSA.

1. Overcooked or fried starch: Noodles are starched at high temperatures of 130 to 140 °C; excessive frying or overcooking can result in noodles that are too dark or crispy, affecting texture and taste.

2. Debris: Small particles, often the result of overcooked or burnt ingredients, can contaminate the noodles, affecting quality and safety.

3. Grease: Some noodles may have uneven oil distribution due to the frying process, leading to inconsistent texture and flavor.

4. Large holes: Noodles that are kneaded and shaped improperly can develop large holes, which affect the cooking consistency and texture.

To detect any such defects, an inspection system is implemented into the preparation process before the addition of flavors, and during the final packaging phase, ensuring that only the highest-quality noodles are sent out for distribution. This process must be both fast and highly accurate to keep up with the speed of production lines, which often operate at hundreds of blocks of noodles per minute.

The technology stack

At the heart of an advanced inspection solution in one particular case is a combination of image processing from Teledyne DALSA Sherlock AI vision software and the Astrocyte AI training tool, with images captured by Teledyne DALSA Genie Nano and Linea camera systems. These elements of the inspection system work in tandem to provide high-resolution imaging and real-time analysis, accomplishing accurate defect detection.

Sherlock AI is a powerful, flexible machine vision software platform that integrates artificial intelligence with traditional 2D image processing techniques. Astrocyte, a code-free AI training tool, prompts users to collect and label their own images of products, samples, and defects to train user-chosen neural networks. These networks can then perform a variety of tasks such as anomaly detection, classification, object detection, and segmentation. The system is designed for high-speed, high-accuracy inspection in demanding manufacturing environments, such as noodle production.

The AI software has a number of benefits, including AI-driven defect selection; ease of use and quick deployment (simply drag and place images to develop applications); automatic training; high accuracy (image tiling to allow tiny defect detection on large images; and flexibility and scalability (the software supports multiple threads running simultaneously).

For image acquisition in such an inspection setting, one Teledyne DALSA Genie Nano 1280 × 960 Color Camera is positioned above the noodles to inspect the top side of the noodles. The camera is equipped with a white ring light, ensuring consistent illumination for optimal image capture. Below the noodles, one Teledyne DALSA Linea 2K GigE Camera is positioned due to space constraints, using a white line light to inspect the bottom side. The Linea 2K camera’s high-resolution imaging capability (2048 pixels) and high-speed performance make it ideal for detecting defects in a confined working distance, while enabling it to catch all tiny abnormalities such as starch, debris, grease, and dark holes.

Instant noodles are in high demand around the world. Courtesy of iStock.com/Andrii Pohranychnyi.

Speed and accuracy

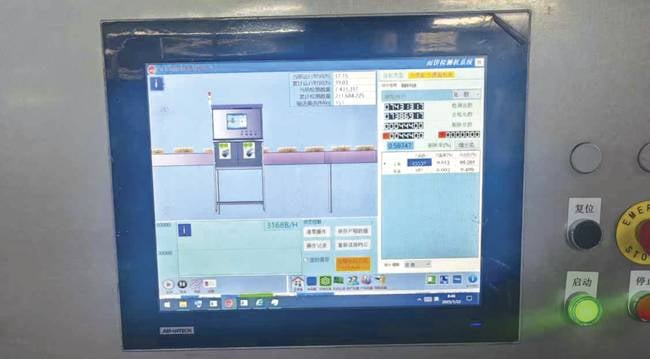

The integration of AI software and machine vision cameras into the production process allows for extremely fast, real-time inspections. While the standard production rate is ~200 ms per instant noodle serving, this new AI-powered solution operates at a speed of ~80 to 100 ms per noodle serving (for top and bottom inspection). This enhanced speed is possible due to parallel running capabilities of multiple threads empowered by the flexible and versatile vision software capabilities, leaving room for even faster processing if demand increases. This level of performance is crucial for high-speed production lines, which can process large volumes of noodles every minute.

While other systems in the market may achieve 96% accuracy, this solution boasts a 99% accuracy rate for all defects, according to a user’s own measurement, except for grease, which remains challenging for all systems due to limited image data. This significant increase in accuracy is enabled by the combined power of the software’s deep learning models, traditional algorithms, and the high-resolution imaging from the cameras. Higher accuracy means fewer imperfect noodles reach the customer, which can result in improved customer satisfaction and a favorable brand image for the producer.

An Asian distributor recently praised the flexibility of this solution, stating that the Sherlock software had helped it outperform the local competition. They cited the value and effectiveness of automatic training, solid multiple AI architectures, versatile labeling tools, and ease of use as well as accuracy achieved by numerous 2D algorithms.

The system monitors the noodle inspection process. Courtesy of Teledyne DALSA.

With real-time, high-accuracy inspections of defects, such as overcooked starch, debris, grease, and large holes, this combination of AI software, training, and cameras is helping manufacturers around the world meet consumer expectations for consistency, safety, and flavor. The speed, flexibility, and accuracy of the system could set a new benchmark in the industry, enabling faster production lines without compromising quality. As the demand for instant noodles continues to grow, this advanced inspection technology will likely play a pivotal role in ensuring that the noodles that consumers eat are always of the highest quality.

Meet the author

Steve Zhu is Teledyne DALSA’s director of sales for Asia, managing more than 30 sales channels and teams throughout the continent. With more than 20 years of experience in the machine vision, automation, and software industries, Zhu has successfully managed and led numerous automation machine vision inspection projects in different industries. Zhu has a Bachelor of Science degree in computer science from Xiamen University in China, an MBA from École Supérieure de Commerce et de Gestion in France, and an Executive MBA from McGill University in Canada; email: [email protected].