Researchers at the National Robotarium at Heriot-Watt University secured funding to develop 3D laser beams that can be shaped to match industry needs and tailored to the task at hand. The funding — from the Engineering and Physical Sciences Research Council, part of UK Research and Innovation — will support the development of lasers for industry and medical applications. Cancer surgery is one such use, where it is hoped that more precise medical instruments could allow the resection of tumors without removing healthy surrounding tissue.

Results from the researchers' work could also be used to improve methods of drilling holes for sensors and cameras on smartphones, and to increase the density of information on semiconductor chips, helping to keep up with increasing demand for more memory in devices.

The funding amounts to £586,000 ($806,000).

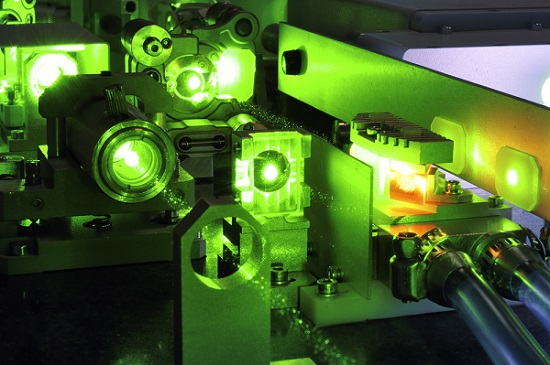

An experimental laser setup for industrial manufacturing use. Courtesy of Heriot-Watt University.

“The new methods we are developing represent a paradigm shift in the capabilities of laser-based manufacturing, making it possible to move between 3D beam shapes with zero down-time and minimal technical know-how,” said Richard Carter, assistant professor of applied optics and photonics at Heriot-Watt University, and the project's lead.

"This technology could also support research in quantum technology, waveguide physics, and the biosciences — anywhere where light must be controlled and manipulated,” he said.

Researchers will collaborate with three industrial partners throughout the project to optimize the approach and the final product for commercial application. Industrial partners PowerPhotonic, Oxford Lasers, and the G&H Group will also support testing in real-life industrial settings. The project’s research involves the investigation of more precise instruments that could allow the resection of tumors without removing healthy surrounding tissue, for example. This type of medical application will be supported by professor David Jayne at the University of Leeds.

Current laser beams cannot be shaped to suit the product that they are being used to manufacture. The new beams will be more precise, efficient, and cost-effective. Lasers are already widely used to make precise incisions and to mold materials into specific shapes. The new approach to laser-based manufacturing depends on melting or vaporizing the material, which means the laser's energy must be focused on the right points. The standard beam shape makes it difficult to tailor for specific manufacturing processes.

Other applications include microscopy, astronomic telescopes, and the fabrication of waveguide devices to support telecommunications and the internet.