Full company details

SCANLAB GmbH

Siemensstr. 2a

Siemensstr. 2a

82178 Puchheim

Germany

Phone: +49 89 800746 0

Fax: +49 89 800746 199

Advanced Laser Scanning Enables High-Precision Vision Corrections

BioPhotonics

Sep/Oct 2022Scan head control increases pattern fidelity, expanding the laser’s use in multiple ophthalmic procedures.AMANDA DOBBINS, STEPHANIE HERZOG, AND MATHIAS STRACKHARN, SCANLAB

Scan heads with innovative controls are already used in many industrial laser-based applications that require the highest precision and throughput. Now the benefits of scanning with zero tracking error are being positioned for ophthalmic applications related to vision correction, in which scan pattern fidelity is critical for a good patient care outcome. This smart control technology enables new and different strategies for diagnosis and treatment compared to the limitations of previous controls, which are affected by tracking error, especially when processing circles, spirals, and freeform structures. These advancements will allow completely new ophthalmic treatments, as well as successful and reproducible refractive surgeries. By using the full dynamic capabilities of the galvo motor in a laser scanning system, operation times can be significantly reduced.

A medical laser treatment. Courtesy of SCANLAB/iStock.com/Szepy.

General market studies show that the ophthalmic laser market includes several thousand installed surgical systems with typical life cycles of 10 to 15 years. Just as importantly, a fast-growing middle class in nations such as China, India, and Brazil is gaining access to ophthalmic surgeries, such as cataract removal and laser photocoagulation (treatment of retinal disease), thus creating additional market demand.

Nowadays, laser-based corneal refractive surgical interventions, such as lasik or lenticule extraction methods, are common. To modify the optical properties of the eye, it is necessary to move a micron-size laser spot with the highest precision as fast as possible over the surgery area to achieve a macroscopic change within short operational times. This is enabled by galvanometer scan systems (Figure 1), which are an approved and widespread technology.

Figure 1. The principle of an xy scanning system positioning a laser beam. Courtesy of SCANLAB.

Tracking errors limit applications

Current standard ophthalmic laser

applications typically use scanners

with conventional analog or digital controls. The control of these systems is constrained due to the tracking error, which is the difference between the command signal and the actual mirror position. The resulting position of the laser energy cannot be pre-calculated, and therefore the use of these scanning systems is limited in applications that include complex structures and elaborate process strategies. The tracking error is also independent from the set processing speed, meaning that the dynamic capabilities cannot be fully utilized, and throughput is therefore limited.

To avoid these tracking errors, SCANLAB developed a digital control technique, which has been deployed in many industrial laser-based applications — including micromaterials processing, laser marking, coding, scribing, and additive manufacturing. All require the highest precision and throughput.

The smart control technology enables new and different scanning strategies compared to conventional controls that are affected by tracking error, especially when scanning circular or spiral patterns and freeform structures. Furthermore, the full dynamic capabilities of the galvo motor are utilized. Thus, operation times can be significantly reduced.

Since many advantages of scan control have become obvious in industrial applications, engineers saw potential in using the technology for laser-based ophthalmological procedures, such as optical coherence tomography and laser ophthalmoscopy.

Pre-calculated scanning

The new scanning control is based on state-space control technology, which is governed by a set of equations describing how a system will evolve over time. The acceleration limiter, which is part of the processing chain of the controller, calculates an acceleration-limited motion profile in real time based on the velocity-limited motion profile received from the scan system’s real-time control (RTC) board. This control board reads the algorithm parameters from the scan system and automatically plans the timing of the scan to obtain perfect corner sharpness, or rounding, if desired. The state-space controller can then follow the acceleration-limited profile without dynamic following errors or tracking delays in the laser scanning process.

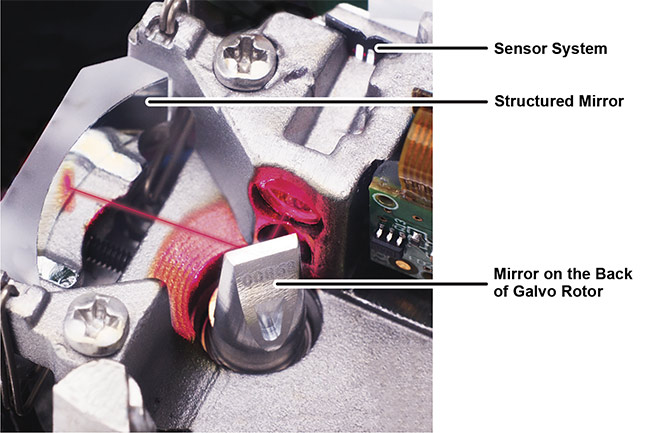

The position detectors are located on one end of the rotor (Figure 2) to measure the scan angle. The scan mirror is mounted onto the opposite end of the rotor. In a first-order approximation, this can be described with a two-mass model, and as a result torsional modes will occur. The new intelligent control algorithm includes a galvo mass model to compensate for potential vibration at high acceleration, so it calculates the actual mirror position instead of assuming that the raw position data from the encoder matches the mirror position. This minimizes position error further.

Figure 2. An internal view of a digital position detector inside a galvanometer scanner. Courtesy of SCANLAB.

This scan control concept operates by always using the full acceleration potential of the galvanometer motor. A scanner that is controlled via this technology calculates a set trajectory during the preview time, which it follows with very high accuracy. This approach reduces the acceleration times to a minimum and at the same time allows a prediction of the motor’s motion profile.

In comparison, conventional controls always have a constant acceleration time, they do not always make full use of the galvo motor’s maximum possible acceleration, and they require notably longer times when the laser is off.

The system follows the trajectory with a constant tracking error. This ensures that the timing between the movement of the mirrors and the laser is fixed, independent of the set speed, but it also leads to unwanted effects such as distortion while doing fast circular or spiral movements (Figure 3).

Figure 3. The processing benefits of SCANahead control (left) compared to conventional scan control (right) in circular movements and arcs. Courtesy of SCANLAB.

Scan systems incorporating the new control concept will follow the given trajectory in real time. Due to this characteristic of the control and its predictability, users can even go as far as calculating motion profiles for the scanner. This allows full control over the scanner motion and adjusting dynamics.

In combination with an RTC board, laser delays and scanner delays do not need to be determined or programmed by the user. The system is capable of automatically synchronizing the scan head with the laser source.

The high dynamic behavior results in a more constant energy deposition along the trajectory, compared to scan heads with conventional controls, because less time is required to ramp up to constant velocity.

Ophthalmological requirements

Compared to industrial applications, scan systems for ophthalmological applications have very specific requirements. All components in the surgical system require the highest possible reliability. In addition, an extended set of operational status signals needs to be provided by the scan system to ensure patient safety. The highest accuracy, predictability, and repeatability are necessary to apply laser light precisely and achieve suitable energy distributions in the cornea.

The high dynamics of the system ensure that patient comfort is achieved by keeping treatment times as short as possible. And, of course, the final scanning solution needs to meet requirements of each individual medical application, with customer-specific mechanical and optical designs, as well as any required safety-related system status monitoring.

The well-known dynamic behavior of galvanometer scanners, together with the constant acceleration, make the trajectories very predictable. This especially enables highly complex scan patterns such as corners, spirals, polygons, or Bézier curves, therefore enabling new ophthalmic treatments, as well as successful and reproducible refractive surgeries. The problematic distortion of circular patterns is overcome by the innovative control technology.

In addition, these scan systems offer a wide range of status signals that can be implemented to ensure the highest possible safety during the operation. Within the machine controls, it is possible to read back the actual mirror position with 10-µs resolution and compare the target with the real position. Since the control concept includes algorithms to compensate for rotor distortion, the remaining errors are reduced to the range of just a few micro-

radians. This improvement in the reliability of the position data stream enables enhanced evaluation of the feedback signals and makes it possible to precisely identify critical errors in the scanner motion and trigger the appropriate fault protection.

Improved dynamic performance

Utilizing the full dynamic capabilities of scan systems with the innovative control concept significantly reduces the patient operation times. Depending upon the structure, a process time reduction of up to 25% can be realized. Due to the high dynamics of the scanner, the mechanical design of the scan heads should be optimized for thermal management and temperature stability.

For the realization of medical devices, a smooth interplay between several components must be achieved. Customization is key to making these complex systems successful. Precise position feedback signals are of utmost importance. However, other status signals may play important roles in the continuous monitoring of critical system properties. These signals can be chosen according to the overall system requirements.

The advanced control concept is usually combined with galvanometer scanners that are equipped with digital position detectors, but this is not a limitation.

In medical applications, analog signal pathways may be preferred for safety and regulatory reasons, making the use of analog position detectors advantageous. A reliable output of these signals and the continuous evaluation of the position can be critical to ensuring patient safety.

Future outlook

New control concepts can facilitate completely new ophthalmic treatments,

as well as successful and reproducible refractive surgeries. Such concepts provide more reliable position signals and an extended set of additional status signals that can be used for system monitoring and overall patient safety. They also improve the dynamic performance by utilizing the full capabilities of the galvo motors.

By substituting the existing machine base with upgraded equipment, along with the development of new treatments, innovative scan control concepts that enable increasing productivity and reliability have a high potential of success in this growing market.

Surgical suites are trending toward combining multiple diagnostic and surgical devices on one platform for end-to-end patient care, greater efficiency, higher flexibility, and a smaller footprint for the ophthalmologist, enabling the best patient treatment strategy. The described control concept can be employed in various ophthalmic procedures that require high scan fidelity. It could also be used in the manufacture and correction of intraocular lenses, either in situ or in vivo.

The complexity of laser scanning tasks will grow, with ever-growing precision and throughput requirements, combined with the need to control the laser properties exactly over time and space. Introducing software-based technologies, such as pre-planning of motion profiles, and information exchange plus synchronization with other hardware devices, will be part of the solution for handling the complexity of next-generation medical laser scanning systems.

Meet the authors

Amanda Dobbins is director of business development for medical and scientific products at SCANLAB. She has a degree in physics and 25 years of experience in specifying optical components for various applications. Dobbins is based in the U.S.; email:

[email protected].

Stephanie Herzog is European sales team leader in medical technology at SCANLAB. Since 2005, she has proved her application know-how and technical competence in

various technical sales roles; email:

[email protected].

Mathias Strackharn, Ph.D., has a doctorate in physics. He is a product manager at SCANLAB, with strategic responsibility for scan systems made for medical applications;

email:

[email protected].