Full company details

Delta Optical Thin Film A/S

Fremtidsvej 1

Fremtidsvej 1

2970 Horsholm

Denmark

LEDs and Multi-Bandpass Filters Work in Tandem to Transform Fluorescence Instrumentation

Photonics Spectra

Oct 2024The technological arcs of a familiar light source and a common component have intersected. Their combination is elevating the potential for advanced designs in fluorescence.POUL SVENSGAARD, DELTA OPTICAL THIN FILM

Fluorescence stands as a cornerstone technology in the realm of bioanalysis. Fluorescence is one of the most sensitive spectroscopic quantification techniques, and fluorescence microscopy methods, including wide-field and confocal microscopy, enable users to identify the locations and movements of certain molecules. This technique finds wide application in live-cell imaging as a result. These technologies, as well as flow cytometry, enable scientists, medical professionals, and biotechnology companies to obtain accurate results, often in rapid time frames.

Instruments that are used to perform fluorescence-based analysis range from compact, purpose-built, single-wavelength devices to large, multispectral instruments. End users and systems designers alike place a premium on the versatility and durability of these instruments. Members of both populations seek devices that can serve multiple purposes — either directly or through reconfiguration.

Especially from the perspective of an end user, this flexibility can reduce capital expenditure by minimizing the need for multiple pieces of equipment.

Meanwhile, for instrument developers, a product portfolio centered around a common instrument design architecture can facilitate a more efficient, streamlined device production process.

Advanced analyses, such as those that are performed on biological reactions occurring in real time, often require the use of fluorescence instruments that are capable of simultaneously emitting and detecting multiple wavelengths. This technical requirement builds on ease-of-use concerns: Users in R&D, clinical, and industrial settings favor instruments that combine the simplicity, cost efficiency, and robustness of basic devices with the versatility of more advanced systems.

To provide solutions that can deliver these coveted qualities, systems designers reap the benefits of multiple-wavelength light sources and optical filters. The availability of LEDs at various wavelengths, paired with custom-designed multi-bandpass optical filters, is vital to the creation of durable, and sometimes novel, fluorescence instruments.

Fluorescence basics

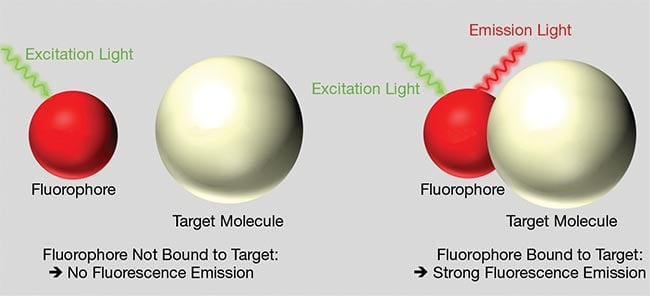

Enhancing contrast for specifically

targeted molecules is a fundamental

deployment of fluorescence-based analysis. This approach uses fluorophores that emit bright light at one wavelength when exposed to the light of another wavelength. Typically, the fluorophore must be modified to bind to, or react with, the specific target molecule. As shown in Figure 1, fluorescence emission is greatly enhanced when the fluorophore binds to the target. By exposing the sample to light at the appropriate excitation wavelength, it is possible to use the emitted light intensity to obtain a direct measure of the concentration of the sample molecule.

Figure 1. When a fluorophore is “free” (left), it does not emit fluorescent light upon excitation. A fluorophore that is bound to the target molecule emits strong fluorescence upon excitation. Courtesy of Delta Optical Thin Film.

One common fluorescence technique uses nucleic acid amplification, whereby viral RNA strands are extracted from saliva and amplified to form viral DNA strands. These strands are then tagged with a fluorophore that binds only to the viral RNA. Emission at a specific wavelength then offers a straightforward indicator of the presence of a virus. This application was in the spotlight as a tool for the detection of COVID-19.

Further, complex reactions — those involving two or more target molecular groups — can be explored using multiple fluorophores, with each fluorophore targeting a specific molecular group. In these reactions, variations in the intensity of emitted wavelengths from different fluorophores correspond to changes in the concentrations of reactants and products as the reactions occur.

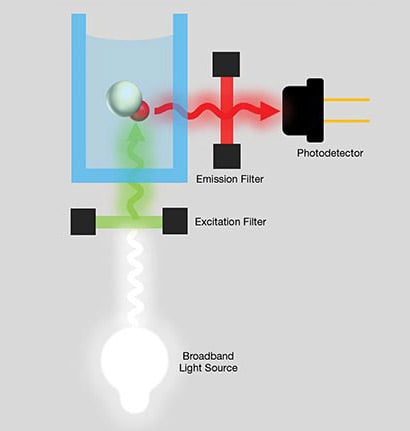

Instrument considerations

The combination of distinct optical components in a single device or apparatus is a principal consideration insofar as it relates to fluorescence instrumentation. Figure 2 shows a schematic setup of a commonly used arrangement for measuring fluorescence from a sample. This arrangement comprises a broadband light source, excitation filter, emission filter, and photodetector. The 90° configuration minimizes the direct light from the source reaching the detector. The excitation and emission filters are selected such that their passbands — the range of frequencies that can pass through — correspond to the peak absorption and emission wavelengths of the fluorophore, respectively. Since fluorophores absorb at shorter wavelengths and emit at longer wavelengths, it is especially important that the excitation filter provides deep-blocking at long wavelengths and that the emission filter provides deep-blocking at short wavelengths.

Figure 2. A simple 90° configuration used to enable fluorescence measurement.

Courtesy of Delta Optical Thin Film.

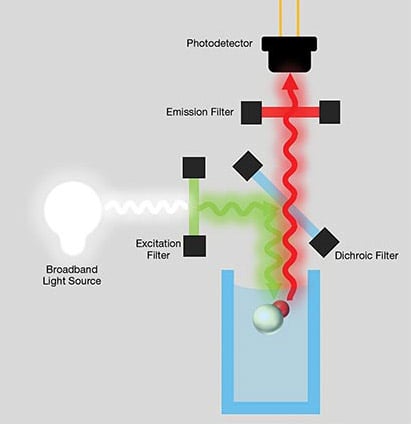

For reflective measurements, it is common to incorporate a dichroic mirror — itself functioning as a filter — into the device configuration (Figure 3). Typically positioned at a 45° angle of incidence, the dichroic mirror reflects the excitation wavelength while transmitting the emission wavelength. It is also common to combine the excitation, dichroic mirror, and emission filter in a cube to save space and simplify system alignment. Since the dichroic mirror functions as an emission filter, the need for out-of-band blocking by the emission filter in front of the detector can often be reduced when compared with the 90° setup.

Figure 3. A fluorescence measurement configuration incorporating a dichroic filter. Such a setup enables a user to perform reflective measurement.

Courtesy of Delta Optical Thin Film.

Multiple-wavelength advantage

Different fluorophores emit at distinct wavelengths, which enables the use of fluorophores to label specific targets with different colors. Therefore, the selection of fluorophores with minimal spectral overlap streamlines the identification of different targets within the sample. This specificity is crucial to accurately identify and quantify individual components in complex samples, such as in flow cytometry, in which multiple fluorophores are often used to characterize different cell populations based on surface markers or intracellular molecules.

The simultaneous detection of multiple molecules through the incorporation of multiple fluorophores is referred to as multiplexed detection. This technology enables the analysis of several parameters or interactions in complex biological systems simultaneously. For example, in immunofluorescence assays, multiplexing facilitates the detection of multiple proteins or cellular structures within a single experiment. This can ultimately yield richer data and reduce experiment time.

Using multiple fluorophores further allows users to probe dynamic processes and functional interactions within biological or chemical systems. By monitoring the fluorescence signals of different

fluorophores over time or under varying

experimental conditions, researchers can elucidate temporal dynamics, spatial organization, and/or functional relationships between molecules or cellular components. This capability is particularly valuable in studies in which the simultaneous visualization of multiple targets provides insights into the underlying mechanisms of biological or biochemical processes.

Instrumentation for multiple wavelengths

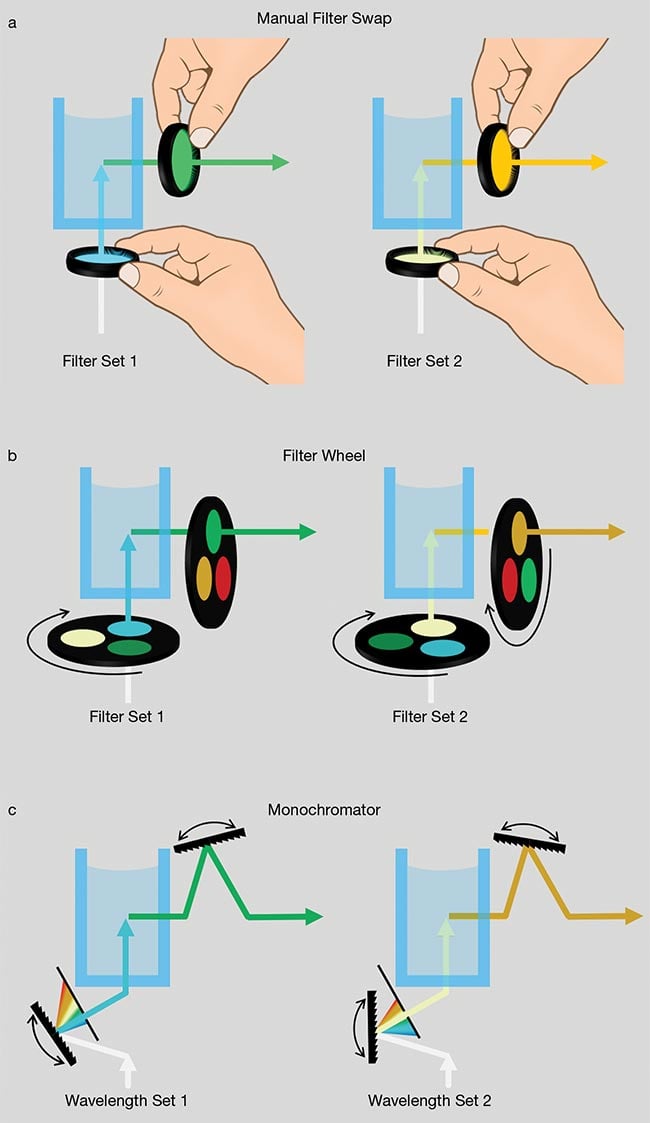

To ensure that an instrument can accommodate excitation and detection at various wavelengths, both the excitation and emission filters must be interchangeable (Figure 4a-c). The architecture(s) of such a system vary; in basic setups, the excitation and/or emission filters are manually exchanged (Figure 4a). A design alternative that may often be more friendly to the end user is to mount the filters in a motorized rotational filter, to in turn provide an alternative to the manual filter swap (Figure 4b).

Figure 4. Fluorescence instrumentation accommodating multiple excitation and emission wavelengths: swapping a filter manually (a); changing a filter via filter wheels (b); selecting wavelengths using monochromators (c). Courtesy of Delta Optical Thin Film.

In still more sophisticated instruments,

both the excitation and emission wavelengths can be adjusted to the exact desired value using scanning grating monochromators (Figure 4c). The tunability of the monochromator can also be achieved by adjusting a pair of linear variable filters relative to one another.

As possible solutions to accommodate excitation and detection at various wavelengths, all three options are plagued by a common consideration: the time required to switch from one filter wavelength to

another. When analyzing numerous samples, the time that allots between wavelength change(s) serves to decrease laboratory throughput. This becomes highly problematic if biological samples degrade over time. In real-time experiments in which multiple fluorophores are active simultaneously, measurements are also ideally conducted simultaneously, or at the frame rate of the detector/camera system.

Scanning monochromators, which function by rotating a diffraction grating with a motor, typically enable a transition from one wavelength to another in a few seconds, whereas manually swapping filters might take several minutes. A motorized filter wheel can typically switch between neighboring filters in ~50 ms.

However, for instruments used in clinical settings, scanning monochromators and filter wheel solutions are often too large and/or expensive. These components are also often sensitive to environmental factors, such as vibration and temperature. Also, scanning grating monochromators typically provide narrower bandpass and higher loss than filters. Simple instruments, using fixed filters, are preferred for such applications.

LED technology road map

The availability of powerful LEDs emitting at any wavelength reflects substantial progress over the lifetime, or technology arc, of this technology. In the 1960s, the first commercial visible LEDs emitted a dim red light. These LEDs were used as indicator lights in small electrical equipment and were not of sufficient brightness to use in or with lighting applications.

The introduction of LEDs based on AlGaAs, in 1987, enabled the development of red LEDs that achieved brightness levels that made them ubiquitous for lighting applications, such as in traffic lights and car brake lights.

Creating high-brightness blue and green LEDs posed significant challenges, delaying their market introduction until the early 2000s. These LEDs are typically fabricated using indium gallium nitride (InGaN). The adjustment of the composition of alloy(s) — and applications, as a result — is fundamental to the production of composition enabling a wide range of colors and applications. Multiple wavelength LEDs retain the inherent benefits of LED technology, such as high-power efficiency compared with alternative and traditional light sources, as well as a longer operational life.

However, LEDs are sensitive to temperature changes, which influence their

emitted spectrum and power. Additionally, variations in the production process can lead to variability in peak wavelength.

And, high-brightness LEDs tend to

carry high upfront costs compared with halogen lights. This potential drawback is frequently offset by LEDs’ long-term benefits, such as lower energy consumption, longer lifespan, and reduced maintenance costs upon implementation.

With high-brightness LEDs now available at a range of visible wavelengths, it is possible to find an LED that matches the absorption peak of almost any fluorophore. LEDs emit light in a relatively narrow spectral band, minimizing the amount of out-of-band ambient light. This characteristic can, in some cases, relax requirements for out-of-band blocking compared with solutions that use broadband halogen sources.

It is currently common to combine an excitation filter with an LED, as well as beam combiners that enable a user to combine beams from different LED sources in one excitation beam. Alternatively, users may select an LED that can emit several colors, with a multi-bandpass filter positioned in front of the source. Furthermore, LEDs can switch on and off in nanoseconds, making them ideal for multiplexed fluorescence and other applications where fluorophores must be excited at different frequencies.

Multi-bandpass filters

In their earliest iteration, optical filters used for fluorescence spectroscopy were comprised of colored glass or polymers. More advanced interference filters in use today can be optimized to match the exact absorption and emission spectra of certain fluorophores.

As an alternative to color filters, early interference filters were manufactured using thermal evaporation that resulted in soft coatings that were not durable and required sealing. The fabrication process for these filters itself necessitated the deposition of thin layers of dielectric materials with different refractive indices and thicknesses on a glass substrate. The key advantages of these filters were their customizability for specific applications

as well as superior performance in terms

of in-band transmission, out-of-band blocking, and edge steepness. The introduction of ion-assisted deposition (IAD) and plasma IAD (PIAD) enabled high-volume manufacturing of durable hard coatings with high performance. Today, PIAD is the preferred technology for many fluorescence filters.

More complex filter designs require a greater number of dielectric layers. The manufacturing of complex optical filters, such as multi-bandpass filters, requires significantly more material to be deposited than simpler single bandpass filters. Although the PIAD process can be used, it requires opening the vacuum chamber to add more coating material, which is detrimental to both final cost and final performance. The introduction of magnetron sputtering has enabled the deposition of large amounts of material required for multi-bandpass filters in a single coating run, making this technique the preferred technology for more complex filters.

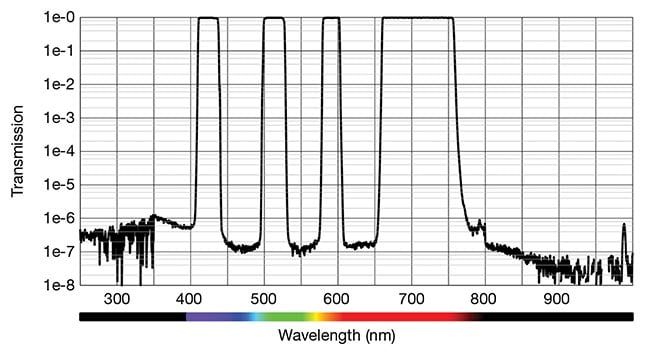

Figure 5 shows the performance of an advanced filter manufactured using magnetron sputtering — namely, a quad-bandpass filter on a single substrate. The filter exhibits nearly 100% transmission in four distinct bands and out-of-band blocking of OD6.

Figure 5. An example of a quad-bandpass filter, manufactured on a single substrate, in application. Courtesy of Delta Optical Thin Film.

Dynamic combination

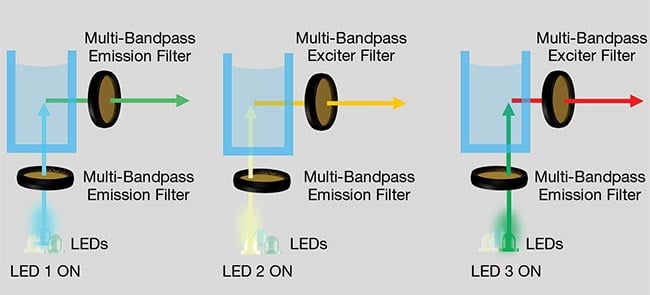

Combining the performance advantages of powerful LEDs at any wavelength and custom-designed multi-bandpass filters, Figure 6 shows a three-wavelength version of one possible system design. This design uses an array of LEDs that are turned on one at a time to excite specific fluorophores. A single multi-bandpass excitation filter, with center wavelengths matching those of the LEDs, is used to filter the excitation light. On the emission side, a multi-bandpass emission filter, with center wavelengths matching the emission peaks of the fluorophores,

selects the appropriate emission wavelength for detection.

Figure 6. The multiwavelength fluorescence instrument uses three LEDs, sequentially turned on, plus a triple-bandpass exciter filter and a triple-bandpass emission filter. Courtesy of Delta Optical Thin Film.

There are several benefits to this type of design. The LEDs can be switched on and off very quickly, allowing fluorescence from multiple fluorophores in the sample solution to be measured almost simultaneously. Further, the instrument has no moving parts, making it extremely stable in various environmental conditions. Also, with both LEDs and filters having long lifetimes, the instrument itself is also very durable. And the use of LEDs as the light source — and the absence of motor drives — results in low power consumption, making the instrument more sustainable than alternative instruments. Finally, the ruggedness

and low power consumption also enable the creation of hand-held and battery-operated instruments.

Meet the author

Poul Svensgaard, CEO of Delta Optical Thin Film, has more than 30 years of managerial experience within high-tech companies,

including in optical filter technology with Delta Optical Thin Film; email:

[email protected].