Embedded Cameras

While usually performed during medical device manufacturing, some machine vision inspection takes place during medical device operation. A case in point comes from Cognex. The Natick, Mass.-based supplier of vision systems has a line of medical embedded vision products that are similar to traditional solutions but in a more compact form that is attractive to machine builders and OEMs.

In a fundamental way, these embedded solutions are like everything else the company does. “Cognex’s bread and butter is vision inspection,” said Jörg Vandenhirtz, senior business development manager for life sciences for the company’s ViDi Deep Learning and Advantage Vision Engines (Europe) division.

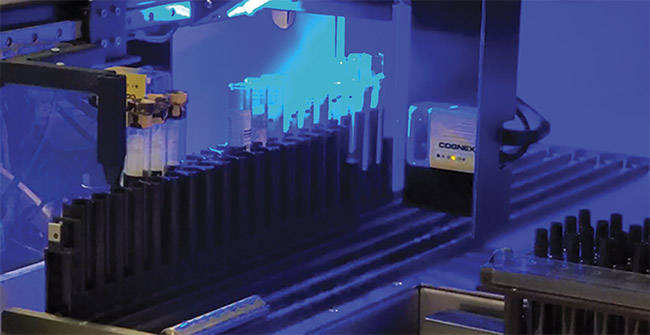

To provide an example of vision inspection during operation, he pointed to the PerkinElmer Janus G3 Blood iQ system. This medical device automates genetic analysis of blood. In many respects, it functions like a compact factory, handling perhaps 10,000 small blood-filled tubes daily.

Machine vision and deep learning enable multipoint aspiration of blood samples for genetic analysis. Courtesy of Cognex and PerkinElmer.

Embedded cameras inspect and analyze these tubes, running presence/absence checks to ensure the tubes are where they are supposed to be. Cameras also look for fluid levels, even going so far as to differentiate among and pinpoint the location of particular types of blood cells after a sample has been centrifuged. Armed with such information, the system can extract white blood cells, for instance, and then analyze them.

Another vision task is to simply determine tube size. No standard exists, and the system needs to know the dimensions of the object it is dealing with. Vision systems can provide this information.

From an inspection perspective, this application presents challenges. The cameras must be small because they have to fit within the tight confines of the available space while staying below allowed heat dissipation levels. At the same time, the camera needs about a 10-cm field of view — the general size of sample tube. Inspecting an entire rack of tubes requires about a 50-cm field of view.

Another challenge has to do with the object that is being analyzed: blood. Centrifuging, for instance, separates blood into red and white cells as well as plasma. However, the exact location of each layer, which can be quite thin for white cells, varies from tube to tube.

“You have the typical biological variation,

as well as tube and package variation, so embedded deep learning is the way to go,” Vandenhirtz said.

Machine vision solutions help automate the

operation of genetic blood analysis. Courtesy of Cognex and PerkinElmer.

In deep learning, software is shown good

and bad images, using these to derive categorization criteria. However, in medical applications, the overall machine may have to be cleared by regulators for use, which may mean no significant aspect of the system can change. So, freezing the learning process and firmware before putting the machine through regulatory clearance may be necessary. Whether this is the case or not will depend on the particular situation.

Vandenhirtz said that deep learning and

vision inspection in embedded cameras will

become increasingly important and common-place in medical devices that operate like miniature factories.

|