Photonics HandbookIndustry News

TRUMPF and SiMa.ai Partner on AI Lasers

TRUMPF has partnered with machine learning system-on-chip developer SiMa.ai to equip TRUMPF laser systems with AI technology, focusing on the acceleration of complex materials processing. This will include systems for welding, cutting, and marking, as well as powder metal 3D printers.

“Many of the processes we perform are difficult to capture with sensors and difficult to evaluate with traditional machine vision methods, especially for image data, because there are no ‘clear edges’ to detect — melting edges are fluid, and defects are often detected only during the process, especially during welding,” said Jonas Zöller, TRUMPF’s head of R&D software development business center systems. “This is why we need AI extensions to our current sensor methods.”

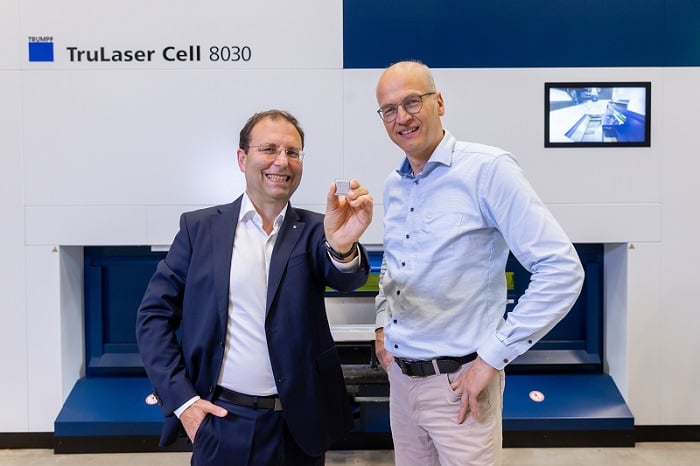

Harald Kröger, (right) SiMa.ai’s head of sales and president of its automotive business, and Richard Bannmüller, CTO of TRUMPF Laser Technology, stand in front of TRUMPF's TruLaser Cell 8030. The laser system is among those set to receive AI integration for process monitoring. Courtesy of TRUMPF.

Through the collaboration, SiMa.ai’s compact AI chips will be integrated directly into the laser systems. AI-optimized sensor technology will monitor the quality of the laser welding process in real time and evaluate more than 3000 images per second.

According to Zöller, following the establishment of live quality assessment capabilities, the collaborators aim to develop “healing strategies" — if it is known that something is incorrect, operators will be able to adjust parameters so as to try to repair the affected sector. In the third stage, it would be possible to adjust the laser system’s parameters live, he said.

“However, this is viewed critically by industrial customers today because, depending on the system, we are in qualified processes,” Zöller said. “There, parameter changes are subject to documentation and approval. That's why this step is the last on the agenda.”

The capabilities afforded by AI-enhanced laser systems are expected to have particular benefits in electric vehicle production. Here, real-time quality inspection during laser welding is expected to replace separate and complex testing procedures. Once the AI capabilities are fully realized, battery manufacturers will be able to increase the quality of their production in real time and reduce reject rates, which could ultimately lead to lower costs for consumers.

In addition to TRUMPF, SiMa.ai has previously entered into partnerships with companies including e-con Systems and Lanner Electronics, targeting Edge- and AI-supported capabilities for multiple applications.

/Buyers_Guide/TRUMPF_Inc/c15237

/Buyers_Guide/TRUMPF_Inc_Laser_Technology_Center/c15238

/Buyers_Guide/TRUMPF_Laser_Marking_Systems_AG/c15240

/Buyers_Guide/TRUMPF_SE_Co_KG/c15241