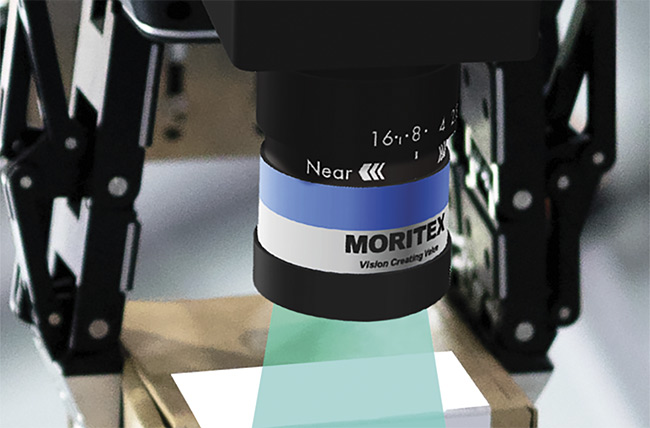

Long an enabling technology for industrial imaging applications, ruggedized lens designs are evolving for systems beyond the factory floor.

JASON BAECHLER, MORITEX NORTH AMERICA INC.

As machine vision applications have expanded rapidly beyond the controlled environments of the factory, so too has the need for ruggedized lens designs that are able to meet more diverse and nuanced requirements. This is not to say that no demand remains in factory automation for shock- and high-vibration-resistant lenses. But solutions for industrialized imaging applications have been implemented for years now, and many of these techniques can be applied to less controlled environments, such as those navigated by autonomous vehicles and drones. Indeed, the volume of vision applications for factory automation could soon pale in comparison to uses outside the factory, while demand for autonomous services and systems continues to evolve and even accelerate, in no small part due to the current pandemic.

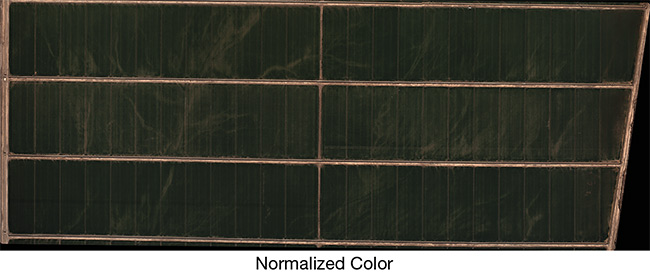

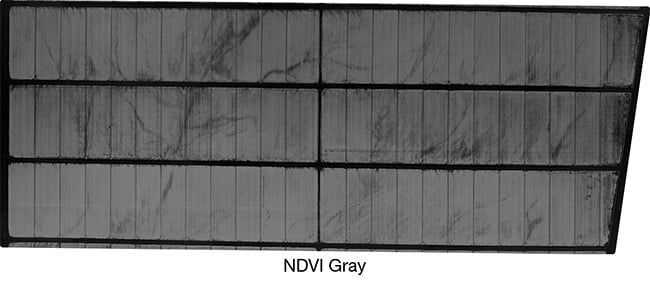

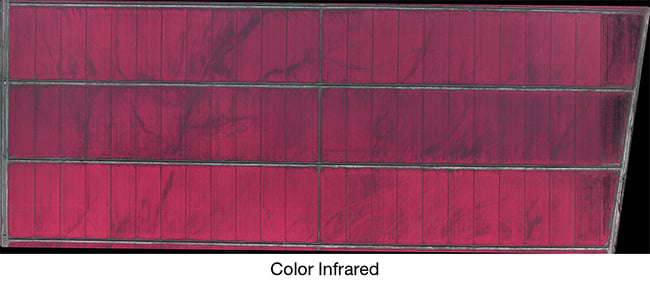

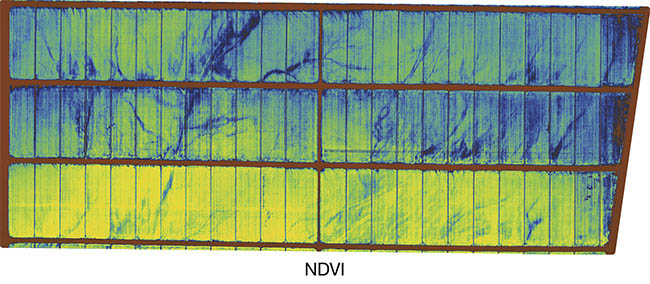

Drones and manned planes equipped with red- and NIR-optimized, high-vibration-resistant lenses are increasingly used for normalized difference vegetation index (NDVI) analysis of farmland. Courtesy of MORITEX North America.

The notion of ruggedized machine vision conjures images of cameras and other hardware housed in bulky, external enclosures. These enclosures add size, weight, and cost to vision systems, which may be acceptable in certain factory automation applications. But the future of vision is heading along a path to system designs that demand more optimized solutions, especially in applications outside the factory. While mechanical ruggedization is an important component of this optimization, it is not the only motivation for designing and producing more robust lenses. Other reasons to optimize optical systems include the need to improve both cost and imaging performance. Imaging performance — which can be defined as optical stability and repeatability — is arguably the most important impetus for optimization, especially considering the stakes of emerging

vision systems designed for autonomous vehicles.

Initial lens considerations

When taken into consideration for a particular solution, most off-the-shelf machine vision lenses are designed to cover a relatively wide variety of applications. The value of traditional fixed focal-length lenses is their versatility and high production volumes. While this versatility allows these lenses to meet the needs of a wide range of applications, it may require trade-offs when used with a particular vision system.

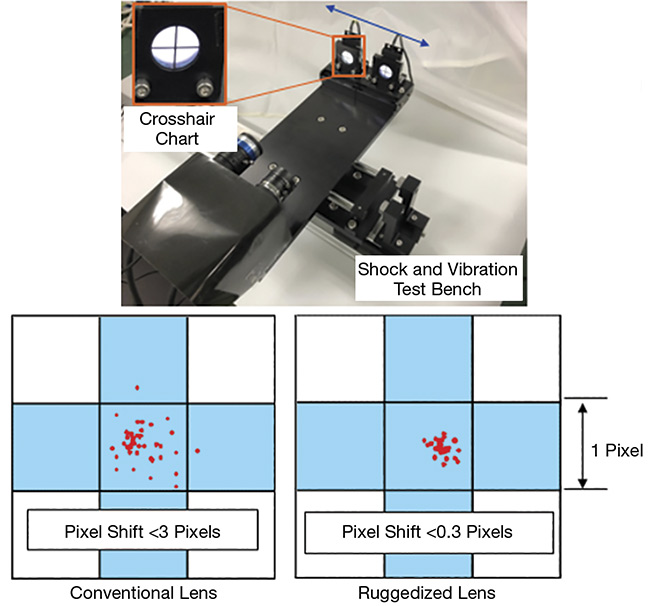

A multidirectional force test bench applies continuous shock and vibration effects to measure image sensor pixel shift. Courtesy of MORITEX North America.

For example, multipurpose imaging lenses designed for factory automation applications have working distances that are almost always finite. The vision systems that they support generally provide controls to help adapt the lenses to various situations by customizing camera and lighting settings. For nonindustrial vision systems operating outdoors, such controls are limited. Operators cannot adjust ambient light from the sun so easily, and imaging working distances tend toward infinity, at least relative to lens designs. When purchasing off-the-shelf lenses for these systems, end users will likely pay more for an optical design intended to cover a broader range of applications that include priorities that do not necessarily align with the user’s situation.

There are also limitations and disadvantages to customizing optics. A common source of frustration stems from the laws of physics, which limit the optics that can be designed based on existing materials. Another challenge involves the comparatively lower production volumes for customized optics, which can impose higher per-part costs compared to standard lenses produced in high volumes. If production volumes are sufficiently high for a customized lens, however, it may be feasible to allocate a portion of the budget to initial design optimization, and then achieve extensive returns in unit price over the life of a product through the simplification of the design.

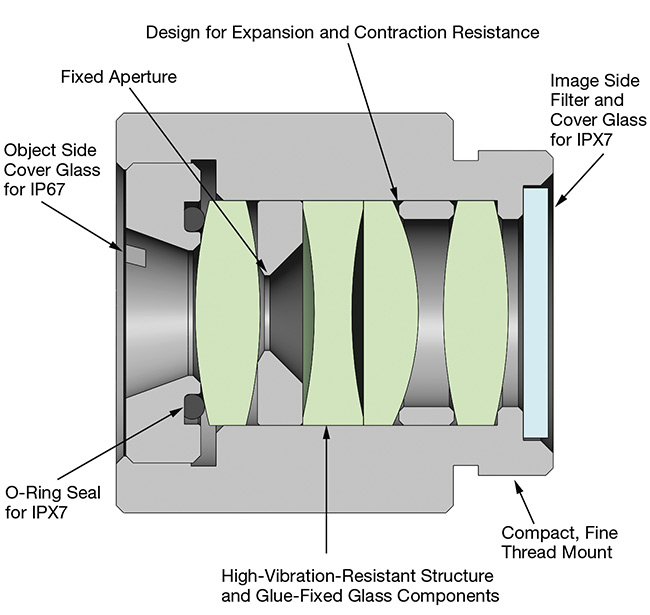

An overview of the ruggedized features of a lens used for autonomous mobile robots. Courtesy of MORITEX North America.

The applicable axiom here is that complex systems generally have higher costs, while simpler systems have more trade-offs in application. Vision system designers should first determine which imaging specifications are most important to their application, with due consideration made to the mechanical and environmental requirements that the lens needs to perform reliably. The

next step is to calculate the cost contribution that the lens will make to the system.

Optical stability

Ruggedization does not forestall the need for lenses to meet the basic requirements for optical stability that underlie repeatable performance. Once these requirements are satisfied, an optical design can then address the potential impact of harsh or hazardous

external environments on optical performance.

For basic applications, it is often enough to choose a particular imaging setting for the f number and aperture stop, or the optimal focus at a particular working distance, to ensure that the lens will perform precisely as expected for a specific imaging configuration. The removal of excess parts and features can reduce complexity, size, and cost, and also permanently fix settings to avoid unwanted changes during use. In other words, the lack of adjustability could actually help the user and reduce the need for support later. Each setup can also be fine-tuned to maximize important specifications. For example, when users scan objects of various heights, such as boxes with barcodes on them, they may need a longer depth of field (DOF). DOF can be exaggerated by increasing the f number — to decrease brightness — and choosing the appropriate focus position.

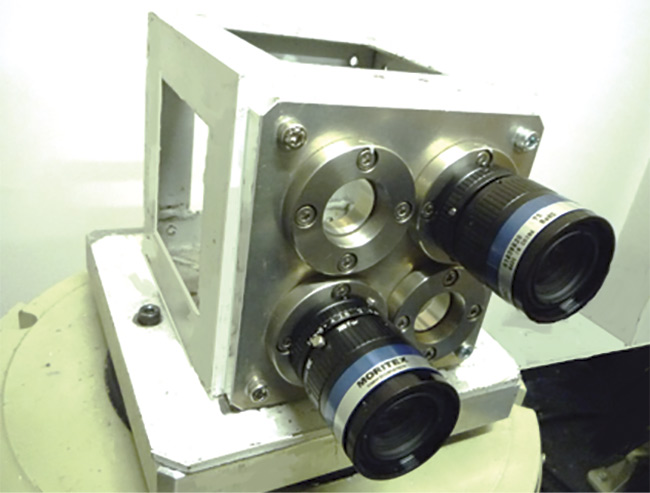

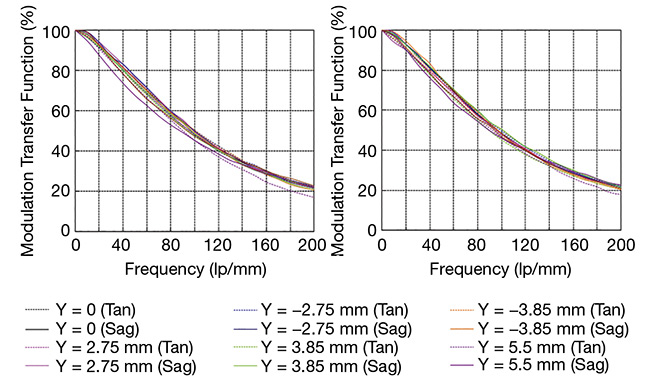

A maximum vibration test bench setup (above). A comparison of the modulation transfer function before (left) and after (right) high-vibration operation. lp: line pairs. Courtesy of MORITEX North America.

For emerging applications such as aerial imaging, which uses the normalized difference vegetation index to determine crop health, wavelengths of interest can be targeted by optimizing the lens with special coatings and/or making other adjustments to the optical components. In addition, the working distance for such applications is in the range of tens of thousands of feet.

So the focus position can be fixed to

infinity. Of course, these optical changes will have other effects. Extending the DOF by increasing the f number, for example, will reduce aperture size and, subsequently, the diffraction limit of the optical system and the maximum resolution.

Imaging applications that require a higher degree of accuracy, such as metrology or stereovision, often require optical components — and their relative position and interaction with the mechanical design — to be configured to minimize the impact of special influences. This can often be achieved by affixing simplified mechanical structures with tighter tolerances to the optical components using adhesives to provide a more secure, tightly spaced assembly. This approach can prevent any changes or drift in the assembly’s optical performance. In more extreme high-temperature environments, special materials with low coefficients of thermal expansion can be used to control the contraction and expansion of lens housings and, in turn, shifts in the positions of optical components. Typically, these materials are considerably more expensive than traditional aluminum and plastic and are reserved for high-end applications, such as semiconductor manufacturing.

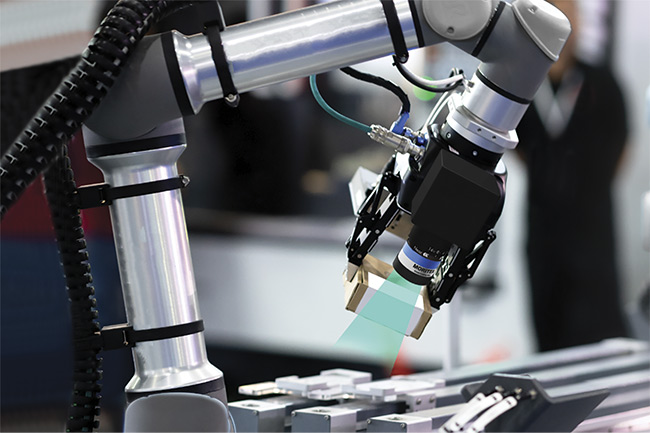

Emerging uses of vision-guided robotics will drive increased demand in specialized and ruggedized optics in the coming years. Courtesy of MORITEX North America.

A primary goal for imaging applications that require high optical stability is the minimization of pixel shift, which can have adverse effects on optical pointing. Pixel shift can result from mechanical forces, such as vibration or shock, that decenter a lens even by a few microns to cause an image to shift to adjacent pixels. If this shift was always uniform and predictable, then image-processing algorithms might correct for the behavior. Unfortunately, such shifts influence vision systems in unpredictable ways. A stable ruggedized lens assembly should maintain image side positional accuracy before and after shock to well within a single pixel, or even less than 0.3 pixels for the most accurate imaging solutions.

Mounting and sealing

Although initial mechanical requirements and constraints are typically taken into account during optical design, additional efforts must often focus on maintaining the integrity of the design and protecting the lens from external environmental factors.

All good machine vision integrators will anticipate the weak points of a lens and camera assembly, with particular attention given to the mount. Standard threaded mounts, such as the popular C-mount, are very convenient for general use. But they do not hold up well in high-vibration environments and are often replaced with C-mount locking clamps. A word of caution, though: There can be trade-offs to optical stability when securing a lens mount with extra force. Lens tilting is an often overlooked symptom of overtightening that can affect optical stability.

From a system perspective, extra care should also be taken to protect the interface between the lens mount and the camera. For example, the C-mount flange focal distance (17.526 mm) is quite long and not ideal when space within an envelope is at a premium. When feasible, a smaller, more rigid threaded option, such as an M12 × 0.5 S-mount, is recommended.

If the aperture and focus haven’t already been fixed optically, the next considerations for a standard fixed focal length lens are the adjustable features of the lens. A robust mechanical design should be the starting point for any modified or ruggedized lens. From there, the aim is to limit the number of moving parts and add a locking mechanism for those that remain. For basic applications, replacing thumb screws with set screws is sufficient. In more demanding environments, a clamping helicoid or double-nut locking configuration is preferred. Custom lens designs can eliminate these weak points altogether, enabling a fully fixed and rigid size-optimized mechanical design.

A growing number of logistics applications call for ruggedized machine vision lenses. Courtesy of MORITEX North America.

Another consideration that is important for outdoor use or washdown applications in food, beverage, and pharmaceutical manufacturing is the implementation of ingress protection measures. The schematic on page 48 shows various vision system design features typically implemented for an autonomous mobile robot operating in a highly variable environment where dust and other debris, water, and cleaning compounds may come into contact with the lens. The core mechanical structure at each end of the lens is sealed with O-rings and also glue to fill in any air gaps and thereby prevent water ingress. Sealed cover glass can add an extra layer of protection for both the object and image side of a lens and, in some cases, can double as a filter or polarizer. Other lens treatments, such as hydrophobic or oleophobic coatings, can also be added to external optical components to repel liquids. Minimizing ingress is required to meet IPX7 and IPX9 system ratings and can also help to prevent the formation of condensation or fogging within the lens.

Quality control

Stringent quality procedures must always be implemented to ensure that

a lens’s performance actually meets

the intended design for a particular

application. To achieve this, optical

design companies apply a host of simulation tools to validate targeted optical, mechanical, and thermal stability; to evaluate fatigue; and to perform tolerance analysis before manufacturing can begin. After prototyping, lens performance should be verified against lens design, followed by additional vibration and temperature testing to ensure that the lens is dependable and to resolve any concerns before mass production. If the budget allows (and the application demands it), highly accelerated life

testing (HALT) or other extreme stress tests can be a valuable way to establish lens and system limits. Even after

production has scaled up, critical applications require that focal length, working distance, and other key

lens parameters be tested at final inspection.

An expanding field of view

Challenging factory automation and measurement applications such as stereovision, gauging, and optical profiling can all benefit from ruggedized lens systems. The application that will likely drive the largest volume of specialized and ruggedized optics in the coming decades, however, is autonomous

systems. From vision-guided robotics to autonomous vehicles and drones, compact, low-cost, lightweight, ruggedized optics are already being implemented to act as the eyes of systems that will interact directly with human beings and eventually become deeply integrated into our world. Industry and agriculture will also seek to improve efficiencies through the use of aerial imaging to monitor the health of invaluable crops and livestock, confirm the integrity of infrastructure — such as pipelines, electrical grids, and bridges — and even provide automated security for mass gatherings.

Whether inside or outside the factory, future imaging applications have almost no limit, and all of them will present unique challenges along the path to an optimized solution. As adoption spreads, it remains important to consider that poorly ruggedized optics can take a production line down or affect the quality of a manufactured product.

But, outside the factory, lens performance in certain environments can affect people’s quality of life, health, and even safety.

Meet the author

Jason Baechler is president of MORITEX North America Inc. in San Jose, Calif., where he manages the company’s business development and regional operations. With a Bachelor of Science degree in electrical engineering and 17 years of machine vision experience, Baechler has grown MORITEX’s business and technology to enable

the success of customers across

diverse market segments; email:

[email protected].