The nuclear fusion experiment that prompted global headlines last December was achieved by a unique laser system. Further progress in fusion energy will require a new class of lasers.

ANDREAS THOSS, CONTRIBUTING EDITOR

It is a rare event when a successful experiment in basic research makes it to the evening news. In December 2022, the U.S. secretary of energy announced a breakthrough in laser-based nuclear fusion. The news was covered in all major media around the world: For the first time in history, humankind had ignited an inertial confinement nuclear fusion reaction that produced a net return on energy. In more starry terms, a research lab produced a tiny sun on Earth.

Seen from above, each of the National Ignition Facility’s two identical laser bays has two clusters of 48 beamlines, one on either side of the utility spine running down the middle of the bay. Courtesy of National Ignition Facility.

Within these reports, many media speculated about a future of clean energy based on laser fusion. Few mentioned that the laser system making headlines was not designed to extract energy or that substantial questions remain before humanity can build a fusion-based power station.

The biggest laser in the world

The light source used in December’s experiment is the biggest laser in the world and combines several unique technical achievements. Requirements for the next generation of fusion lasers, however, will depend on significant advancements in the fusion pathway and other areas. But a few of these developments are already in discussion today.

Several institutions in the U.S. and other nations are conducting research into laser fusion, though it was the National Ignition Facility (NIF), a part of the Lawrence Livermore National Laboratory (LLNL) in Livermore, California, that conducted December’s headline-grabbing experiment. The NIF’s laser is also the largest of its kind. It was conceived in the 1990s, construction began in 1997, and it was completed in 20091.

The NIF source uses 192 beamlines

to generate pulses that add up to about

2.1 MJ of energy in the ultraviolet within 10 ns. The generation of each pulse starts in a master oscillator, an ytterbium-doped fiber-laser emitting at 1053 nm. The pulse is split and fed into 48 preamplifier modules (PAMs) that each include a regenerative amplifier where the pulse energy is increased from about 750 pJ to about 15 mJ using a 4-kW diode array to pump neodymium-doped glass (Nd:glass) rods.

NIF is a fully automated photon factory optimized for 24/7 operation. Courtesy of Lawrence Livermore National Laboratory.

There is a second stage to each PAM: a multipass amplifier through which the pulse travels four times, boosting its energy up to 10 J. The amplification medium is Nd:glass, which is pumped by an array of 12 xenon flash lamps. Within each PAM, the beams also undergo spatial, spectral, and temporal shaping before they are split into four beams and fed into the main amplifier.

In the main amplifier, these pulses are sent through a stacked array of rectangular Nd-doped phosphate glass blocks pumped by thousands of 1.8-m-long flash lamps. Each lamp is driven with 50,000 J per pulse. The total energy needed per pulse is 330 MJ. The laser light is then redirected and optically delayed so that all 192 beams reach the target chamber

at an evenly distributed array of angles.

In the final stage, each pulse, carrying about 20,000 J of energy, is converted from 1053 nm to 351 nm with 50%

efficiency.

A color-enhanced image of the inside of one of NIF’s preamplifier support structures. Courtesy of Damien Jemison.

This frequency conversion is performed in thin sheets of potassium dihydrogen phosphate crystals. Getting such crystals to accommodate the 40- × 40-sq-cm beams adequately is one of the “seven wonders” that the NIF claims for its experimental design. These wonders are unique technical challenges that the NIF personnel and their suppliers overcame to achieve the laser’s current operation.

Another wonder that the NIF lists is the production of the Nd:glass slabs. In fact, the two glassmakers, HOYA Corp. and Schott Glass Technologies, designed a new process of continuous glass production to produce the amplifier material 20× more quickly, 5× more cost-effectively, and with 2 to 3× improvement to optical quality than what previous processes delivered.

A photon factory

The NIF uses industrial processes to produce its unique pulses. It becomes obvious to knowledgeable visitors that the laser lines are closed. There are no knobs for a postdoctoral student to tweak in between shots. Instead, more than 66,000 sensors allow for remote control of the system. Each optic in the beam path has a digital twin that allows NIF staff members to conduct virtual lifetime tests or predictive maintenance.

The whole research facility is optimized for maximum uptime. The technical team works in three shifts to enable its 24/7 operation. Usually, the team conducts experiments on weekdays and performs maintenance on the weekends. The current limitation of four to five shots per day is mainly due to the time it takes to replace target pellets in the target chamber.

The recent success of the NIF’s laser is due in part to the team’s improvements to energy output, which reached 2.15 MJ in December. Demands for more pulse energy must be balanced against the damage thresholds of single optics.

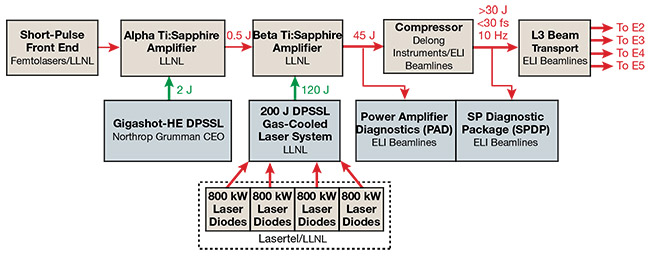

The path toward a futuristic but practical fusion-based power plant will require more efficient laser systems, which points to diode-pumped solutions. Developed at Lawrence Livermore National Laboratory (LLNL) on behalf of the European Extreme Light project, the High-Repetition-Rate Advanced Petawatt Laser System (HAPLS) consists of high-average-power diode-pumped Nd:glass lasers used to drive a short-pulse, broadband, chirped-pulse amplification system. The amplification system is designed to deliver 30-J pulses with durations under 30 fs. The system is currently operating at 3.33 Hz. DPSSL: Diode-pumped solid-state laser. Courtesy of Lawrence Livermore National Laboratory.

NIF scientists have already developed several procedures to cure minor damages using CO2 laser pulses. Nevertheless, they must still recycle 20 to 40 optics each week.

Further improvements in the pulse energy are possible but they will require careful planning within this photon factory.

About future lasers

The NIF was built to conduct experiments for the U.S. government’s nuclear Stockpile Stewardship Program after underground testing was banned in 1992. The NIF was specifically established to ensure the safety of the U.S. nuclear weapon arsenal with its experiments and simulations.

Probing essential questions around energy extraction or fuel breeding to enable a fusion-based power station was not part of the NIF’s original mandate. Nevertheless, it has explored next-generation laser systems optimized for power generation for a long time. Among the important questions it has raised is how to achieve a higher repetition rate and a higher wall-plug efficiency (currently 0.7%) of the laser.

One implication of the recent experiments is the need for high laser energy per pulse. For the fusion physics conducted now, about 2 MJ of laser energy is necessary per pulse. For a power station based on such a laser emitting 10 pulses per second, this would imply a source that delivered an average power of at least 10 Hz × 2 MJ × the IR-to-UV conversion efficiency to produce 40 MW. Assuming

a laser efficiency of 15%, this would create waste heat of 230 MW, even as the total power demand for the laser system ends up at 270 MW. This is a very rough estimation. More realistic plans might include regains from the cooling system,

heat from the tritium breeding, and so forth. A more detailed discussion of potential lasers for inertial fusion energy was published in 20102.

A schematic diagram of the High-Repetition-Rate Advanced Petawatt Laser System (HAPLS) built at LLNL for ELI Beamlines. Courtesy of ELI BL.

It is useful to also consider this challenge from the other side, namely, from the practical needs of an actual power plant designed to deliver a minimum

1 GW of electrical power capacity. At a pulse rate of 10 Hz, this would assume the laser source delivers 200 MJ of fusion energy per pulse. For this “Gedankenexperiment,” the conversion efficiency from fusion energy to electrical power is estimated at 50%. A higher repetition rate could reduce the required energy per pulse or increase the capability of the fusion power plant. The laser system, however, should have a safety margin to keep maintenance low, and backup lines to minimize downtime.

Particle physics sets the stage

Before the recent successes at the NIF, fusion was a rare topic in laser development. More common were discussions on the implementation of lasers in particle acceleration. Accelerator schemes such as the one operated by the European Organization for Nuclear Research (CERN) had reached a scale measured in kilometers, making further upscaling a questionable endeavor. To the excitement of particle researchers, laser physicists had developed the more compact method of laser wakefield acceleration that allowed electron acceleration through intense laser pulses shot into plasma. The laser pulses traveling through the plasma created waves on which electrons start surfing. Surfing on an electromagnetic wave accelerates the electrons to the speed of that wave, which is light speed in the medium. With some sophistication, such electrons can be used to accelerate protons or even larger ions.

A pump diode module similar to those used in the HAPLS. It is designed to deliver 500 W per bar, 20 kW per tile, and 100 kW per row. After recent upgrades, it is capable of delivering 900 kW per module. New systems achieve over 1.8 kW per bar. Courtesy of Leonardo Electronics.

This idea provides particle acceleration within the size of typical laser systems and opens a pathway to accelerator schemes that are 1000× shorter than the common radio frequency-based particle accelerators at CERN or other premises. Laser wakefield accelerators assume laser peak pulse powers in the order of 100 TW and beyond. Accelerator schemes further prefer repetition rates in the kilohertz range. This leads to parameter sets that are relevant for fusion lasers.

Regardless of application, these estimated power requirements should make the need for more efficient laser systems obvious. Diode-pumped solutions are mandatory for delivering higher wall-plug efficiency. Furthermore, because a power station needs to generate a continuous energy supply, the laser repetition rate must be increased to several hertz, at minimum.

LLNL developed one such diode-pumped high-energy laser system: the High-Repetition-Rate Advanced Petawatt Laser System (HAPLS). It was developed under contract for the European Extreme Light Infrastructure (ELI) project and its beamlines facility (ELI BL) near Prague3.

The HAPLS consists of high-average-power diode-pumped Nd:glass lasers for driving a short-pulse, broadband, chirped-pulse amplification system. The amplification system is based on Ti:sapphire sources and designed to deliver 30-J pulses with durations under 30 fs. The system is currently operating at 3.33 Hz.

Laser fusion, as shown at the NIF, requires intense energy emitted at nanosecond-pulse lengths, similar to those produced by the HAPLS pump laser, which delivers 200-J pulses with 20-ns duration 10× per second at 1053 nm. Its power amplifiers are pumped by four diode arrays with 800 kW of peak power each, to deliver 10 kW of average power all together. The diodes can run up to 20 Hz and deliver pulses of 300-µs duration into an area measuring 5.6 × 13.8 sq cm.

Another interesting system was implemented at HiLASE, a research institution located next to ELI BL’s facility. HiLASE’s BIVOJ system, developed at the Central Laser Facility in Didcot, England, is a diode-pumped, cryo-solid-state laser that delivers 146 J of pulse energy, 10-Hz repetition rate, and 10-ns pulse durations at the 1030-nm wavelength.

In January 2023, Japanese laser provider Hamamatsu Photonics announced a pulsed diode-pumped system offering 100-J output at 10 Hz that it designed specifically for fusion research. More new systems are emerging. For example, the team at LLNL’s Advanced Photon Technologies (APT) group is developing a short-pulse version of the HAPLS pump laser that aims to provide a simplified and more energetic upgrade to the Linac Coherent Light Source at the Stanford Linear Accelerator Center, according to Tom Spinka, project manager and chief scientist of the APT group.

“The new architecture, originally dubbed the Scalable High-Power Advanced Radiographic Capability, or SHARC, eliminates the lossy second [titanium-doped sapphire] stage of the HAPLS laser system, ultimately delivering about 5× higher energy than the HAPLS at the same peak power and repetition rate,” he said.

The laser will be developed in parallel with performance ramping of the HAPLS laser at ELI BL to its full design specifications.

The target chamber for the NIF under construction. Holes in the target chamber walls provide access for the laser beams, as well as viewing ports for diagnostic equipment. Today, pulses from the NIF’s high-power lasers converge at the center of the target chamber within a few trillionths of a second of each other and are aligned to the accuracy of the diameter of a human hair. Courtesy of National Ignition Facility.

If this design is further refined, one could envision a move toward continuous diode pumping and multipulse extraction. This would be far easier to achieve with diodes and would facilitate higher repetition rates, as well.

Other ignition schemes

The NIF achieved ignition when the energy emanating from the laser-driven fusion hot spot drove a cascading number of additional fusion reactions. All fusion processes need a balance of pressure, temperature, and confinement time for the nucleons to overcome the coulomb repulsion of charged particles. The process

releases energy once this barrier is crossed.

The threshold for repulsion is smallest for hydrogen; the larger the core’s charge, the more energy is required to achieve fusion.

The NIF has demonstrated one way to achieve these energies. Several laser-fusion startups, however, are exploring other pathways, such as fast or shock ignition, where one ultrashort pulse compresses the target and ignition is achieved with the help of a second pulse. This “proton fast ignition” applies laser pulses under 1 ps to accelerate hydrogen nuclei that then impinge on another target to trigger ignition there. The German/U.S. startup Focused Energy is taking this

approach, for example.

Another startup, Marvel Fusion, is pursuing proton-boron fusion.

“We intend to accelerate particles with a conversion rate larger than 50% from laser to particle energy,” said CTO Georg Korn.

To accomplish this, the company plans to use ultrashort pulses packing at least 50 kJ of energy to ignite fusion in boron4. Such a proton-boron fusion delivers energetic helium nuclei and very few low-energy neutrons, which would reduce radioactive waste from the fusion process. “The laser efficiency is crucial for effective fusion,” said Korn. “Therefore, we developed a short-pulsed laser with direct diode pumping.” This will be important because the wall-plug efficiency of subpicosecond high-energy, high-average-power systems to date is poor and repetition rates of at least 10 Hz are needed.

Outlook

No doubt, the recent success at the NIF has raised a great deal of interest in laser-based fusion. This photonic approach competes with magnetic confinement systems that have already attracted more than $5 billion from investors. But it was laser fusion that in December achieved ignition — self-sustaining hydrogen combustion — to deliver a net return on energy. This unique achievement will drive the development of future laser systems and target technologies for laser fusion.

There are now bigger questions on the table. The NIF applied 2.15 MJ per pulse in the recent experiment: Are there pathways to ignition that require less energy? Are there ways to extract more energy out of the target? Answers to the first question may alter the requirements for future fusion laser systems and allow more feasible schemes. Emitting multiple megajoule pulses per second is still an unexplored regime for laser performance. New

experiments are on the way, so time will tell what form future fusion lasers will take.

Despite these open questions, some conclusions can be reasonably drawn about future laser fusion systems.

First, high-energy, high-average-power pulsed lasers will be needed. Building them as line-replaceable units (as suggested at the NIF) is advisable. Such a high number of beamlines will also lead to cost constraints. “We need to completely rethink lasers, take advantage of cost reductions through economies of scale, and find new ways to produce lasers the way we produce cars today: highly automated, with mass-produced components and low maintenance costs,” said professor Constantin Haefner, managing director of the Fraunhofer Institute for Laser Technology (ILT). “But in the century where light, lasers, and optics continue to play an ever-increasing role in society and industry, this is a worthwhile undertaking.”

Second, the development of fusion laser technology will be of mutual benefit for laser-based particle acceleration and all kinds of secondary sources. Laser fusion research will drive the development of a new class of high-power pulsed lasers that may open the door to many new industrial applications, just as the fiber lasers for telecom drove the development of game-changing laser technologies for materials processing applications.

References

1. M.L. Spaeth et al. (2016). Description of the NIF laser. Fusion Sci Tech, Vol. 69, No. 25, www.doi.org/10.13182/fst15-144.

2. A.M. Dunne (Nov. 9, 2010). Timely delivery of laser interial fusion energy (LIFE).

Presented at ANS 19th Topical Meeting on the Technology of Fusion Energy, Las Vegas, www.osti.gov/biblio/1017996.

3. C.L. Haefner et al. (June 26, 2017). High average power, diode pumped petawatt laser systems: a new generation of lasers enabling precision science and commercial applications. Proc SPIE, Vol. 10241, 1024102, www.doi.org/10.1117/12.2281050.

4. V. Istokskaia et al. (February 2023). A multi-MeV alpha particle source via protonboron fusion driven by a 10-GW tabletop laser. Comm Phys, Vol. 6, No. 27, www.doi.org/10.1038/s42005-023-01135-x.