Multispectral and hyperspectral imaging systems capture images at multiple wavelengths, which traditionally requires sophisticated and expensive equipment. Making the right decision on lighting can keep added costs in check.

MATTHEW BRANCH, PROPHOTONIX

The demand for advanced imaging systems across industrial and scientific applications has led to the evolution of multispectral and hyperspectral line-scan imaging technologies. These systems are pivotal for tasks such as quality control, material inspection, and scientific research. However, the complexity and costs associated with these technologies can be significant barriers to widespread adoption. This article presents strategies to reduce system complexity and cost by using less complex and more affordable line-scan cameras, combined with optimized multispectral and hyperspectral line lights.

An epinephrine pen incorporating capsules. Courtesy of ProPhotonix.

Multispectral imaging captures data at specific wavelengths across the electromagnetic spectrum, while hyperspectral imaging captures a continuous spectrum of data across a wide range of wavelengths. These technologies allow for the detailed analysis of materials based on their spectral signatures, making them invaluable in fields such as agriculture, food processing, pharmaceuticals, and manufacturing.

Line-scan cameras capture images one line at a time as objects move past the camera, making them ideal for the inspection of continuous processes in manufacturing. In multispectral and hyperspectral imaging systems, these cameras must capture images at multiple wavelengths, which traditionally requires sophisticated and expensive equipment.

Reducing complexity and cost

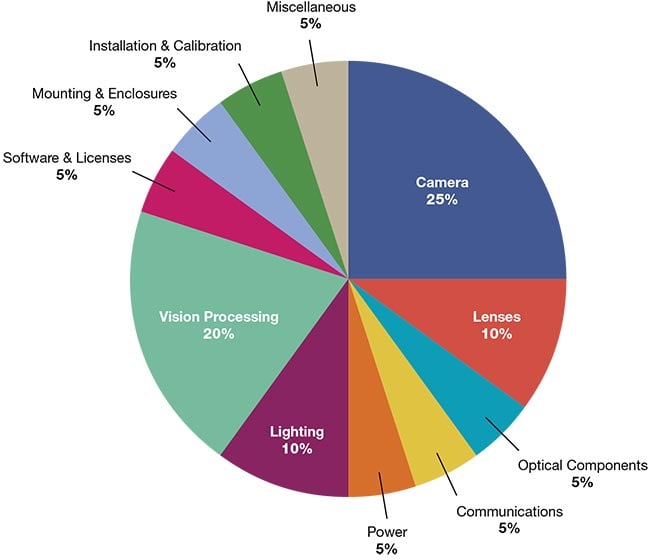

Setting up a line-scan machine vision system involves several key components, each contributing to the overall cost.

Contact lenses. Courtesy of ProPhotonix.

A typical breakdown of costs as a percentage of the overall system cost. Courtesy of ProPhotonix.

Unfortunately, lighting tends to be considered long after the camera and related lenses, optical components, software, and vision processing equipment are already specified. This places not only limitations on the available expenditure allocated to the lighting but also significant design limitations on the quality and overall suitability of the lighting to the specific application in question. Too often the end user will purchase lighting that is considered good-enough and, more importantly, does not overshoot the budget allocated to the overall vision system. To avoid this scenario, a better approach is to consider the relevant lighting much earlier in the design process, and to consider configuring it in such a way that allows one to reduce the overall system cost by minimizing the need, for example, for unnecessary optical components and the overall spend on cameras. In this article, a number of case studies are discussed whereby system designers were able to reduce the overall machine vision system cost by identifying the most appropriate line light solution earlier in the specification process.

Achieving maximum contrast

Certain applications require imaging a product that comes in a variety of colors. In one such example, an epinephrine pen manufactured by a medical device integrator needed to be imaged, with the QR code and serial numbers recorded to a database. As a medical device application, accuracy and reliability was of the utmost importance. Unfortunately, some of these colors proved to be difficult to image reliably, particularly the contrast between the QR code and serial number against the background color of the blue capsule, which was consistently low. Additionally, imaging a second color, taupe, consistently resulted in errors. Adjusting the camera settings, such as exposure time, gain, and gamma correction, did not fully resolve this problem.

The correct lighting can often make the object of interest stand out more sharply against the background, and this could achieve sufficient inspection accuracy even with a lower-resolution camera. This approach can be particularly beneficial in high-speed applications in which reducing resolution can also increase frame rates, thus improving throughput.

The solution was a fully adjustable red,

green, blue, and white COBRA MultiSpec LED line light from ProPhotonix. Equipped with a standard graphical user interface (GUI), the end user could customize the emission spectrum of the line light to the color of the capsule to maximize the contrast and reduce errors.

Since only multiple capsules of a single color were imaged at any one time, various spectral “recipes” could be selected from a database whenever necessary, and maximum contrast could be generated at any time regardless of the color of the capsule.

Overall, the lighting solution allowed the end user to switch from a color line-scan camera to a simple, low-resolution monochrome line-scan camera, with the associated cost savings and reduction in image processing requirements.

Switchable lighting

This technique is often used in machine vision systems in which a monochrome camera is used to capture high-resolution color and NIR images by sequentially using different wavelengths of light.

In the case of contact lens packaging inspection in the medical device industry, packaging can be imaged for defects, such as missing lenses, incorrect lens placement, and packaging defects, ensuring high accuracy and reliability in detecting even the smallest anomalies.

The identification of contact lenses within the blister packs is difficult when using visible lighting alone, due to the transparent nature of the contact lenses, and the saline solution in their packaging. However, these lenses typically absorb UV wavelengths, and so the use of this wavelength in an imaging system is advised to improve blister pack occupancy detection.

Instead of using a multispectral camera that is sensitive across the UV, visible, and even NIR bands, it is possible to switch to a simple monochrome camera, such as the Teledyne DALSA Linea ML color line-scan camera, with a responsivity curve stretching from 300 to 1000 nm (where responsivity is ~2 DN/nJ/cm2) with a peak at 650 nm (~17 DN/nJ/cm2).

In this case, one must set up the line light in such a way that each of the RGB and UV channels can be sequentially strobed. Each of the wavelengths is assigned to an independent strobe group within the multispectral lighting system, independently triggered through a dedicated 0-5V TTL signal. A 100-kHz frequency (at a duty cycle of 10%); a total delay and response time of <1 µs per wavelength; and high-resolution color images, including a UV component, allowed for detailed inspection, including the identification and occupancy of contact lenses within the blister packs.

Absorption bands

The compositional effect of wavelength absorption is a common technique used to determine the presence of certain materials. For example, it is well known that water has absorption peaks for wavelengths within the shortwave infrared (SWIR) part of the spectrum. Three notable absorption bands occur at ~970 nm, ~1450 nm, and ~1940 nm, due to overtone and combination bands of the O-H stretch vibrations in the water molecule. However, the 1450-nm peak is the strongest and most commonly used of these bands in the detection of water in organic materials.

In one such application, the end user was required to set up a SWIR imaging system to detect organic contaminants present during the inspection of plastic food pallets to prevent cross-contamination. Each pallet was subjected to a cleaning routine and then, using SWIR imaging, confirmed to be clear of organic contaminants before being loaded with foodstuffs for distribution.

Initial tests were performed using a COBRA HyperSpec SWIR system with full coverage of the 950- to 1750-nm spectral band, using a combination of 11 different wavelengths to maximize spectral “flatness” and stability. The use of a hyperspectral SWIR camera was required, but this led to a “light starving” of the bands, relevant to the water absorption itself (the 1450-nm wavelength and a reference wavelength).

From the hyperspectral analysis, two wavelengths were chosen for maximum contrast: the 1450 nm and a second, shown to be least affected by water absorption. Thereafter, the lighting was simplified to a two-wavelength multispectral lighting system and additional LEDs of either wavelength were employed to further maximize the intensities of both wavelengths, as working distances between the light source and food pallet in the application was of the order of ~300 mm.

The Cobra MultiSpec SWIR line light used to identify the presence of organic contaminants through the identification of water. Courtesy of ProPhotonix.

As a result, the end user, while still using a hyperspectral line-scan camera, was able to simplify the line light from a hyperspectral source to that of a two-wavelength multispectral source to achieve the end result of a reliable and repeatable means for identifying organic contaminants on food pallets at long working distances of ~300 mm.

Vision systems combined

Significant advancements in sensor and camera technology have occurred in recent years, with the introduction of multisensor cameras with advanced prism technology. One such example is the JAI Sweep+ SW-4010Q. These cameras offer the end user the possibility of reducing the complexity and cost of the overall vision system if the correct lighting is specified and configured correctly ahead of time.

One such end user, involved in food sorting, previously had two line-scan imaging systems operating independently within the sorting system: one dedicated to VIS-NIR imaging using RGB and NIR using a standard CMOS sensor, and the other a SWIR imaging system using two separate SWIR wavelengths and an indium gallium arsenide sensor.

LED lighting was already employed within the sorter, with multiple arrays of standard surface-mount-device (SMD) LEDs required to meet the intensity targets necessary for the reliable and consistent qualification and identification of foreign matter. However, line speeds were significantly limited, due to the low power of the SWIR sources. A more compact solution was required that not only provided higher intensities of SWIR illumination but also either met or exceeded the system’s current RGB and NIR intensities. Additionally, independent strobing of each of the NIR and SWIR channels was required.

A modified multispectral light system was configured for the end user, incorporating all the wavelengths required into a single line light source. The simplification of the line light — from a multiple LED array source to that of a single 1D array of LEDs comprising an interlaced combination of RGB, NIR, and SWIR LEDs — was only possible using advanced chip-on-board technology. This technology allows for a more compact and intense source of LEDs; when incorporating LEDs with varying wavelength, the resulting illumination proves to be more intense and spectrally uniform than their SMD counter-

parts. Coupled with this line light solution, a prism-based, multisensor RGB plus SWIR camera could be used, thereby offering both VIS- and SWIR-based imaging along one optical axis.

The resulting illumination contributed to a more reliable inspection and sorting process, with overall sorting speeds of up to 60,000 tons/h. The most notable benefit and cost savings associated with this approach, however, are related to the overall simplification of the machine vision setup. Initially, the multiple linear arrays of SMD LEDs and separate VIS and SWIR imaging systems required complex alignment, extensive power and communications cable routing, and multiple electronic printed circuit board assemblies. By switching to a single multispectral lighting source, the end user was able to

simplify alignment and reduce electronics, cables, and connectors to a fraction of the previous complexity. This ultimately resulted in a simpler, more cost-effective line-scan machine vision system with higher reliability and throughput.

Reducing system complexity and costs in multispectral and hyperspectral line-scan imaging systems is achievable through strategic use of simplified line-scan cameras and optimized line lights. By focusing on tailored solutions that match the specific needs of each application, it is possible to achieve high-quality imaging results without the prohibitive costs and complexity traditionally associated with these technologies. Collaboration with manufacturers and leveraging integrated vision systems further enhances the potential for cost savings and system simplification.

By implementing these strategies, industries can benefit from advanced imaging capabilities while maintaining manageable budgets and streamlined operations. This approach not only makes advanced imaging more accessible but also paves the way for innovative applications across various fields.

Meet the author

Matthew Branch is senior product manager at ProPhotonix, an LED light and laser diode module manufacturer of machine vision lighting systems worldwide; email: [email protected].