Laser Measurement Adds Precision to Engine Core Technologies

Partners from aerospace manufacturer Pratt & Whitney and Virginia Tech have developed an optical technology to calculate engine thrust to allow high-fidelity measurements of gas turbine engine parameters including velocity, temperature, and density. The laser-based and optical instrumentation technique, called filtered Rayleigh scattering for thrust measurement (FRST), offers significant advantages compared to traditional sensors and probes, and will support the development of smaller and more thermally efficient engine core technologies and could enable the measurement of non-CO2 particulate emissions in flight.

FRST relies on ultraviolet light and the principle that light scattering back from air molecules passing over a laser-illuminated area can provide information about the gas flow field, from which thrust can be derived. Applied to a turbofan engine, the light is provided by a laser beam directed across the turbine’s gas path, while the resulting scatter is recorded by a high-performance camera and “filtered” for corruptions in the signal.

Though the concept of Rayleigh scattering has been known for centuries, the recent work and resulting technique uses recent advancements in computing power, laser, and camera technology to apply the technology to a turbofan engine, said Todd Lowe, a professor of aerospace engineering at Virginia Tech. According to Lowe, the collaborators expect the technology to have application in the development and certification of aircraft engines, beyond the current capability.

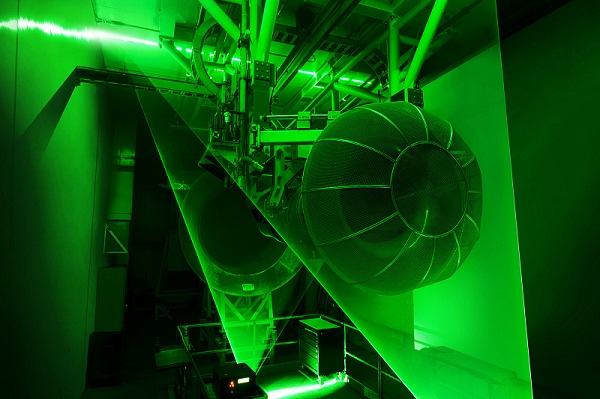

Filtered Rayleigh scattering for thrust measurement (FRST) is demonstrated on a test engine at Pratt & Whitney Center of Excellence at Virginia Tech. Courtesy of Virginia Tech.

Traditional sensors and probes used for thrust measurement can be difficult to install and they can cause flow blockage, particularly on smaller engine cores where space is limited. FRST potentially eliminates the need for these sensory devices. Further, it presents opportunities to measure non-CO2 particulate emissions, which could contribute to industry-wide efforts to understand and mitigate the environmental impact of those emissions, particularly with regard to contrail formation.

So far, Pratt & Whitney and Virginia Tech’s joint research team has successfully measured engine thrust using FRST optical techniques on a research engine in a test stand at Virginia Tech. The group recorded similar accuracy to that of traditional sensors and probes, and teams are working toward flight-testing the technology.

/Buyers_Guide/Pratt_Whitney_Measurement_Systems_Inc/c12063

/Buyers_Guide/Raytheon_Technologies/c12593