MARIE FREEBODY, CONTRIBUTING EDITOR

The range of benefits that laser texturing technologies offer, which span those in the critical areas of precision, performance, and efficiency, are direct drivers to the expansion of laser texturing’s application into multiple industries. At the same time, the evolution of laser texturing-based technologies suggests that these technologies hold great promise to continue to spur innovation and improve the performance of many widely used materials, components, devices, and finished products.

Courtesy of GF Machining Advanced Solutions.

From improved grips and adhesives to aesthetically pleasing cell phone frames and light displays, laser texturing is essential for the fabrication of devices used in numerous markets.

By definition, laser texturing is the process of changing the surface properties of a material through laser light at a specific wavelength and intensity. Unlike chemical or mechanical methods, laser texturing enables noncontact, highly precise patterns and modifications of a material’s surface with no tool wear or variance of process quality over time.

In this way, laser texturing falls somewhere between laser marking and cutting processes: Unlike laser marking, texturing involves some amount of material removal, but not full removal, as in laser cutting. Physical modifications are typically in the micrometer and sub-micrometer range(s).

Plastics, composites, and glasses

Essentially, any material that can absorb laser radiation at a specific wavelength can be treated via laser texturing. This includes polymers, composites, and glasses. Changing the topography of the surface of the material can create or affect specific effects that improve necessary performance and application qualities, such as friction, adhesion, and wetting as well as optical characteristics. Changes that are induced via texturing may also influence the way the material interacts with any surrounding fluid, air, or biological condition.

Beyond low roughness average values, laser micromachining offers precise control over surface finishes. Laser texturing exists between the techniques of laser marking and laser cutting: It offers some amount of material removal, like in marking, though not full removal, as in cutting. Courtesy of GF Machining Advanced Solutions.

Certain laser parameters must be optimized, in addition to those with the material. These parameters include laser power, fluence, pulse duration, wavelength, and scanning speed — each of which must be optimized based on the properties of the material in use. For example, UV nanosecond-pulsed laser sources are generally used for plastics, ceramics, and glass due to the high photon energy.

Femtosecond (fs) pulsed lasers have the added advantage of multiphoton absorption mechanisms, which grants these sources widespread use in texturing materials that are typically transparent to the laser wavelength. “Even with infrared fs laser pulses, it is possible to achieve the antifogging effect on glass by introducing tiny ablation spots that are barely visible for the naked eye,” said Bogusz Stepak, R&D director of laser microprocessing

at Fluence.

The viability to use femtosecond lasers to texture numerous types of materials makes these sources enabling technologies for a range of applications even beyond industrial. “High-performance, high-reliability fs lasers make it possible to perform laser surface modification of transparent brittle materials, such as sapphire and glass, a variety of ceramic compositions, and some types of polymers used in medical applications,” said Mark Keirstead, N.A. sales manager at GF Machining Advanced Solutions. Nonmetals, such as polymers, absorb long wavelengths and reflect shorter wavelengths, and the opposite is true of metals. This means that short-wavelength lasers are needed to process metals and longer-wavelength lasers are needed for nonmetals.

Femtosecond lasing enables an exception to this letter of this rule, because these lasers can be used to process all solid materials, even in the infrared. The ultrashort pulses provide the possibility of high-speed patterning of the surface with periodic structures that are comparable in size with the laser wavelength — and up to 10× smaller.

Among commonly used industrial lasers, CO2 lasers have the longest wavelength, which makes them preferred sources for processing many polymers and composites. “These laser sources are typically paired with galvanometer scan heads to quickly sweep the focused beam across the surface of the material. Two-axis scan heads can process simple planes while three-axis heads can process complex 3D geometry,” said Justin Conroy, global application engineering manager at Novanta.

Elsewhere in the realm of industrial lasers, both metals and nonmetals benefit from the flexibility and high efficiency provided by fiber lasers. At Allied Scientific Pro, for example, the process of laser texturing metals, such as aluminium, uses high average power pulsed master oscillator power amplifier fiber lasers.

“We use a 300-W average power,

between 100 and 350 ns of pulse width and pulse frequency in the kilohertz range,” said Yuhao Qiu, photonics specialist at Allied Scientific Pro. “For optics, the main [parts are] mirrors and

an f-theta lens.”

The centerpiece features a brass dial, engraved and decorated with a femtosecond laser for superior quality and aesthetics (top). The stainless steel exterior showcases five-axis capabilities, with deep engravings in white and blue, complemented by laser brushing to integrate the bezel with the outer cylindrical surface.

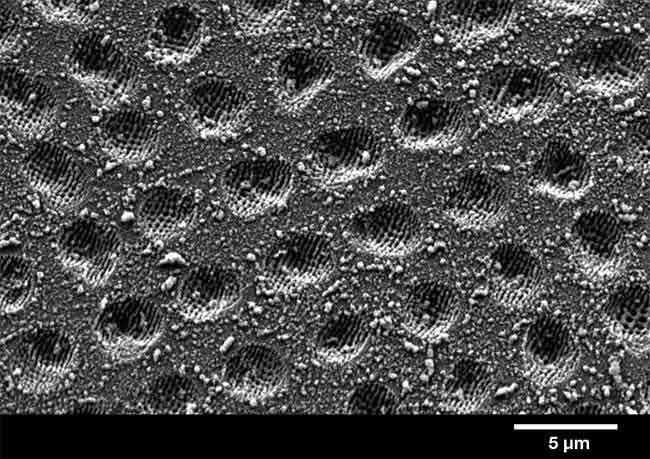

An image of a glass substrate processed using direct laser interference processing (DLIP) with a spatial period of 4 µm (bottom). Courtesy of GF Machining Advanced Solutions.

Although optimized laser parameters depend entirely on application, material, and desired outcome, processing methods are typically very similar, and require only subtle adjustments to laser power, speed of marking, and pulse control. Common methods include direct laser interference patterning (DLIP) and direct laser writing. The exact method required further depends on the resolution or feature size that is needed.

Laser-patterning ceramics

Laser patterning involves the creation of specific geometric patterns on the surface of a material. It is commonly used to create microchannels, grids, and other intricate designs, with applications in opto- and microfluidics, sensor fabrication, and electronic device manufacturing. With ceramics, laser patterning can create microchannels on the material surface to enhance heat dissipation in electronic devices. A recurring challenge in laser processing ceramic materials involves

results than can appear visually misleading: Some laser sources can pattern ceramic surfaces so they appear suitable upon visual inspection, but may weaken the tensile strength of the material. Defining the optimal laser parameters without causing any change in the tensile strength of the finished part is imperative for medical implants and aerospace and defense applications, among others.

For the most common applications of laser patterning, laser-textured surfaces can improve light extraction, enhance signal transmission, and enable precise control of optical properties. This is useful in the fabrication of microelectromechanical systems (MEMS), photonic devices, and sensors.

A wood handle is laser textured to improve handgrip qualities. Courtesy of Fluence.

“In ceramics, laser texturing can enhance mechanical properties, alter electrical conductivity, or improve surface wettability,” said Ilya Noskov, technical marketing manager in the Laser Marking Technologies Division at Keyence. As it relates to medical implants, laser texturing is used to increase the chances to achieve a positive outcome in osseointegrations. In aerospace and defense, laser texturing is necessary for surface modifications of electronics for better performance and improved wear resistance of components, Noskov said.

Direct laser interference patterning-glass

Direct laser interference patterning involves the use of two or more coherent laser beams that intersect on the material’s surface to create an interference pattern. This pattern can produce periodic structures with high precision and

uniformity. The method is suitable for creating large-area textures and is

commonly used in the fabrication of diffraction gratings, photonic crystals, and antireflective surfaces.

“In DLIP, several laser beams that are obtained from a single laser source are recombined at the material surface, creating an interference pattern with different geometries like lines or dots,” said Andrés Lasagni, a professor at Technische Universität Dresden, Germany, where he also serves as chair of laser-based manufacturing. “The material is then locally modified by melting or ablating at the interference maxima positions.”

DLIP is highly effective for modifying

the surface of glass materials used in display technologies. By creating precise patterns on the glass surface, laser texturing can enhance light extraction and improve display brightness. This makes it ideal for use in the production of OLED and liquid crystal displays, where it is important to achieve high-resolution patterns that enhance the overall visual performance.

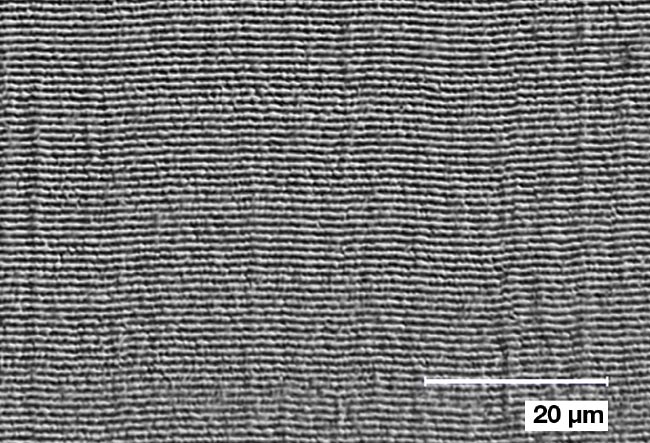

A depiction of laser-induced periodic surface structures on stainless steel, induced by an infrared femtosecond laser. The processing throughput for the depicted sequence is 22.8 cm2/s at 60 W average power. Courtesy of Novanta.

The effectiveness of DLIP extends to modern advancements in automotive lighting using LEDs. For automotive lighting applications, LEDs demand optical components that appropriately disperse LED light for safety as well as for branding and design purposes. Plastic covers, which have micro-optic surface structures that have been transferred from a glass mold to the plastic part, disperse light evenly. The micro-optic features are laser-machined into the glass mold using femtosecond lasers, which are capable of processing the small geometries with sharp edges and no burr or slag.

Direct laser writing composites

Direct laser writing is a technique in which a focused laser beam is used to write patterns directly onto the surface of a material. This process involves the selective removal or modification of material to create the desired texture.

As in DLIP, direct laser writing is particularly useful to make high-resolution patterns and involves combining two or more distinct phases to precisely modify the composite’s surface without affecting its bulk properties. In aerospace applications, for example, the technology is used to create microstructures on composite surfaces to improve aerodynamic performance and reduce drag. Additionally,

direct laser writing can be used to fabricate complex conductive patterns on composite materials for electronic

applications.

Direct laser writing is limited to the diffraction limit when focusing the laser beam, which means typical feature sizes range from ~10 to 50 µm. On the contrary, DLIP enables resolutions even better than 1 µm.

Again, laser texturing composite

materials brings together considerations to both practicality and design aesthetics for numerous applications.

“In composites, laser texturing can

tailor surface properties to improve bonding with other materials, reduce friction, or enhance aesthetic appeal,” Noskov said. “Applications include automotive parts (improved bonding with coatings), sports equipment (enhanced grip), and aerospace structures (optimized surface characteristics),” he said.

Laser ablation of polymers

Laser ablation involves using the energy from the laser to remove material from a surface by vaporization or sublimation. This technique is highly precise and can be used to create complex 3D textures. For example, rubber shoe soles are textured to improve grip performance, and plastic cell phone frames are textured to alter aesthetics for a more premium or metallic look without adding weight.

Laser ablation is also effective for materials that are difficult to machine using other traditional methods. It is widely used in applications such as medical device manufacturing — specifically to improve the adhesion of coatings in packaging and controlled fluid flow in microfluidic devices — and aerospace component fabrication, and also in materials research. The laser texturing of polymers can improve surface properties such as wettability and adhesion as well as optical characteristics.

A material’s absorption for a specific wavelength is key to achieving an efficient process without charring, while the correct output power is needed to achieve the process speed needed. CO2 lasers meet these demands for polymers, effectively interacting with the surface and enabling high control of laser pulsing for varying surface properties.

“Oftentimes the texture consistency requires very good power stability from the laser source to get acceptable results, as in the case of roughing surfaces for consistent glue adhesion,” Novanta’s Conroy said. Novanta’s ti100-HS CO2 laser model is used for high-end texturing and additive manufacturing applications, he said.

Another consideration is that the approach to processing differs for thermoplastics compared with thermoset plastics; thermosets are more likely to chemically degrade and char, and thus more process parameters may be needed. In addition, a pulsed laser with high-energy pulses may be required to quickly ablate the material without degradation.

“UV and deep-UV fs lasers can perform ablation and selectively activate the polymer surface to make it more hydrophilic without damage to volume,” Stepak said. “And, both chemical and geometrical modification can be achieved at the same time with the highest precision even for medical-grade polymers.”

Future challenges

Laser texturing hard and brittle nonmetal materials requires a high-quality machine capable of processing homogenous surfaces on oftentimes complex shapes. Further, the various approaches to laser texturing often require a seamless pattern projected onto a highly contoured 3D part. For the most part, five-axis control within the laser machine is required. This in turn means that sophisticated software is needed to ensure that the application is performed correctly.

“If the part surface is not a flat plane, then it can be difficult for more basic laser systems to focus the beam consistently on it,” Conroy said. “More complex multi-axis scan heads or multi-axis part handling equipment is needed to keep the surface at the focus point of the laser beam at all times.”

To address this set of requirements, several European-level projects are focusing on implementing high-power short and ultrashort laser sources combined with new optical concepts and advanced sensors. The goal of these efforts is to distribute laser energy more efficiently across the material’s surface to prevent heat accumulation that could damage the material’s intrinsic properties, while also enhancing productivity.

“The aim is to efficiently distribute this energy to avoid heat damage and boost productivity,” said Lasagni, who is also the coordinator of the CLASCO (Climate Neutral and Digitized Laser-Based Surface Functionalization or Parts with Complex Geometry) project.

At the same time, the emergence of new polymers and ceramic materials is placing correspondingly new demands on the performance capabilities of laser systems. Because new materials have novel absorption curves, and absorption curves are unique to materials, the determination of new laser wavelengths, to better absorb new material types, is a constant undertaking.

These challenges have not diminished the need for a non-damaging green solution that eliminates the multiple steps required in a chemical etch process. Laser texturing continues to displace chemical etching processes in existing as well as new application areas.

“With femtosecond lasers, patterning or surface functionalization can be performed on any material. The latest studies show the possibility of achieving durable functional surfaces such as antifog without using chemicals and multiple processing steps,” Stepak said.

“This is truly green technology. Modern femtosecond lasers provide power levels that will enable the manufacturing of a new generation of functional surfaces on the mass scale.”

The ongoing investigation to use laser surface texturing to modify the thermal properties of materials further supports laser texturing’s robust and enduring application potential. Thermal management is a critical challenge across industries, and laser surface modification is a promising technology to solve this problem. Features created via surface ablation can alter a material’s surface area or emissivity and improve heat transfer efficiency.

“Ultrafast lasers have become increasingly popular in these surface texturing applications,” said Mark Turner, CEO and founder of Turner Laser Systems. “In addition to being able to delicately ablate the surface into a different texture, they also offer the ability to modify the surface into highly periodic nanostructured patterns through a mechanism known as laser-induced periodic surface structures (LIPSS).”

Other applications of LIPSS include altering optical properties, wetting properties, friction, wear, de-icing and controlling bacterial growth.

“With higher power levels available and the cost per watt of ultrafast lasers decreasing, commercial viability has significantly improved, opening up more applications,” Turner said. Still, according to Turner, motion control over complex-shaped parts remains a challenging task in the engineering domain.