CAMBRIDGE, England, July 11, 2025 — Laser-assisted cold spray (LACS), an additive manufacturing technique for aerospace and other industries, overcomes the high-temperature and material limitations of traditional manufacturing methods, enabling greater design flexibility, efficiency, and precision in production.

Developed at the Center for Industrial Photonics at the University of Cambridge, LACS uses localized heating of a supersonic powder stream with a laser to deposit metals and cermets (composites of ceramics and metal) to build, coat, and repair parts. The LACS process can be used to create original parts or to add coatings and features to existing components. It enables fast, on-demand fabrication of coatings and component repairs.

The research team, led by professor Bill O’Neill, pioneered additive manufacturing methods using powder bed fusion and cold spray, a technique for rapidly fusing powdered metals, cermets, and polymers without melting them. The team initially used nitrogen as a carrier gas for the powder, but switched to helium when it found that helium was necessary to achieve optimal deposition when working with high-strength materials like titanium and aluminum alloys. “Helium, because of its lower molecular weight, enables higher particle velocities in cold spray, enhancing impact energy and improving adhesion to the substrate,” O’Neill said.

But helium is costly, and the team’s efforts to recycle the gas were only partially successful. Additionally, the equipment necessary to recycle the helium restricted the size of the parts that could be manufactured. “We needed to find a more practical solution for these high-strength materials, and that’s when we started investigating using lasers,” researcher Andrew Cockburn said.

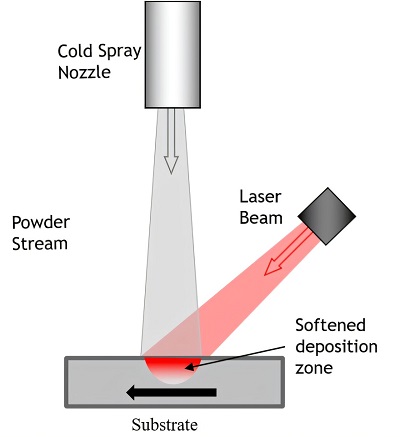

The team invented LACS to facilitate more efficient deposition of solid-state material powders. During the LACS process, a laser is used to heat the deposition site locally. This reduces the substrate yield stress, resulting in a strong bond between the materials without the need for melting. Beyond eliminating costs associated with using helium as a carrier gas, LACS offers multiple advantages over other cold spray methods.

The localized laser preheating in LACS softens the substrate, improving particle bonding and deposition efficiency. This results in stronger coatings, especially for high-strength materials like titanium and refractory metals.

Deposition occurs at a lower particle frequency, which ensures that the structure of the powder is retained in the coating or part. This helps protect materials with properties that are easily damaged, such as nanostructured coatings and rare earth magnets.

LACS enables deposition of harder, more challenging materials than standard cold spray methods. Materials like cermets, refractory metals, and oxidation-resistant alloys typically have poor adhesion in traditional cold spray.

The laser’s thermal input reduces residual stresses in the coating, improving its mechanical properties. The thermal input also minimizes porosity, enhancing the structural integrity and durability of the deposited layer.

Unlike traditional thermal spray methods, LACS keeps the substrate below melting temperature. The thermal impact on the substrate is minimal, making LACS suitable for use with heat-sensitive materials and applications. The team showed that the relatively low-temperature, localized laser heating used in LACS allows new material to be added without negative side effects.

Laser assistance allows the manufacturing process to operate at lower gas temperatures than standard cold spray — for example, at 400-700° C, compared to up to 1200° C for cold spray. This reduces power consumption and simplifies system design.

Coatings can be quickly added at up to 10 kg per hour, and coating properties can be fine-tuned by creating customized powders to introduce special characteristics, like magnetics or enhanced wear resistance, into the deposits. Grading composition provides local control of material properties and reduces the stresses at the interfaces between dissimilar materials.

Additionally, LACS eliminates the need for costly molds or extensive machining, making it valuable for industries that require low-volume, high-precision parts.

LACS equipment set-up to add a coating to repair a panel aircraft wing. Courtesy of the University of Cambridge.

The capability to build and repair custom parts is especially valuable for industries that involve high-precision, high-strength, low-volume manufacturing of complex parts, like aerospace. LACS offers a sustainable, cost-effective, efficient option for repair, and, in more extreme cases, re-manufacture from a base part. Traditional repair techniques like welding are unsuitable for high-performance applications, because the heating needed to adhere the new material to an existing component impacts the strength and reliability of the repaired part.

As with 3D printing, the LACS equipment has the potential to be programmed to build to a specified design from a computer model, quickly turning digital designs into tangible products. “This is transformative for many industries, allowing custom parts to be created and repaired on demand in a short time frame,” researcher Martin Sparkes said.

Illustration of the LACS process, showing the laser beam heating the powder deposition zone. Courtesy of the University of Cambridge.

The next step for the lab will be to enhance the capability of LACS to 3D print a shape. The team is exploring several ways to achieve this goal, including mounting the part on a moving arm to allow it to be moved in 3D space and increasing the control over the direction of the powder stream to produce crisp, smooth edges.

“Currently, we have little control over the shape of deposition of the powder,” O’Neill said. “This is not an issue for coatings but presents a significant restraint for part-building applications. Our next goal is to find a solution to this limitation, and we already have some very promising results.”

Finally, LACS reduces material waste and energy consumption compared to traditional methods. “Developing a new generation of innovative manufacturing technology with advanced processing capabilities could significantly aid the transition to net zero,” O’Neill said.

Aerospace, process, energy, biomedical, and other industries can use LACS to make high-performance coatings and critical component repairs more efficiently. And, O'Neill said, “The ability to customize the properties of the materials is a real game-changer and has a huge range of potential applications.” LACS could be used to produce lightweight components for electric vehicles and aerospace, create hydrogen storage systems, enhance wind turbine maintenance, manufacture energy-efficient batteries and fuel cell components, and develop heat exchangers for industrial energy savings and catalyst coatings for carbon capture.