In Transition from Battlefield to Industry, Dry Laser Cooling Makes a Splash

Laboratory-developed laser equipment is often deployed on the battlefield. A laser cooling approach traveled the reverse course.

By Laurynas Ukanis, Deividas Andriukaitis, Lukas Rimgaila, and Jim Burnett

As lasers expand further into industrial, research, medical, and military applications, end users are placing increased scrutiny on system cooling requirements. All lasers require a form of thermal management. The appropriate method depends on both the laser design and its operating environment: If the heat load fluctuates, for example, a user must account for both the laser’s range and rate of change.

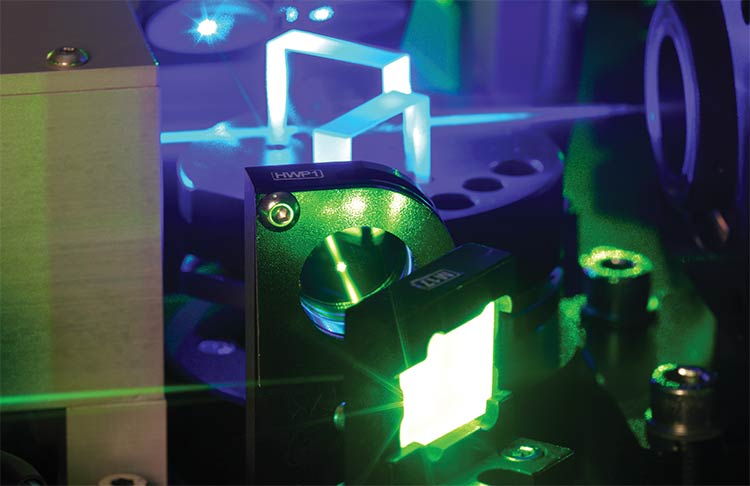

Courtesy of EKSPLA.

Regardless of scale and power, overheating can lead to efficiency losses, wavelength drift, and shortened operating lifetime. Low-power lasers operating in stable environments with broad temperature tolerances can often rely on simple air cooling. On the other hand, higher-power systems, or those with tight tolerances, require more advanced methods. Today, system wall-plug efficiencies range from 0.1% to nearly 80%, and power levels can span from milliwatts in measurement and marking applications to multiple kilowatts in heavy manufacturing.

Cooling design is therefore not a peripheral consideration. Instead, it is a critical factor that is central to ensuring reliability and performance across all systems and applications.

Core considerations

Users must evaluate several parameters when determining the optimal cooling solution. Maximum allowable laser

temperature, temperature tolerance

(±X.XX °C), ambient air temperature or available facility water temperature, and

cooling load — the excess heat that must be removed — are among the most critical considerations.

Historically, laser manufacturers provided system integrators with only basic cooling requirements: coolant temperature, flow rate, and pressure. Selecting a cooling system was left to the end user, and stand-alone liquid chillers were the most popular option.

Conventional chillers use single-speed compressors paired with large reservoirs to stabilize the coolant temperature during load fluctuations and compressor cycling (Figure 1). While this is an effective mechanism, this approach results in bulky systems that occupy valuable floor space. Moreover, pumped liquid loops

introduce potentially significant concerns in the areas of reliability and maintenance. These include reservoirs that require refilling as water evaporates; water connections prone to leaks that may damage the laser or the electronics; algae growth in the coolant that can compromise performance; and the failure of pumps that ultimately prevents functionality in the whole system.

Figure 1. Left: A typical pumped-loop liquid chiller. These systems use single-speed compressors paired with large reservoirs to stabilize coolant temperatures during load fluctuations and compressor cycling. Courtesy of Aspen Systems LLC.

These problems can potentially create warranty issues for laser manufacturers, since cooling system failures can easily cascade into laser system failures.

Passive versus active cooling

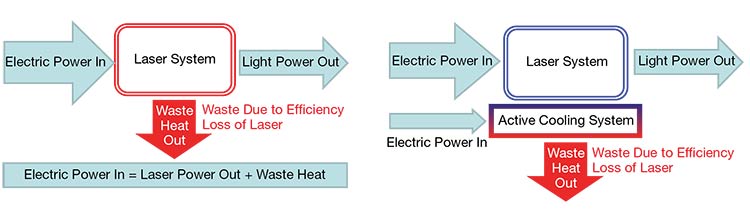

Passive cooling systems stabilize only when the laser’s heat generation balances with heat dissipation to ambient air — which often limits the performance of these cooling systems (Figure 2a). Passive cooling envelops the methods of free convection, fan-assisted cooling, and/or pumped loops without active refrigeration. These methods are unable to reduce system temperature below ambient, and/or maintain a precise setpoint.

Active cooling introduces energy to regulate laser temperature, even below ambient, if necessary. Approaches such as thermoelectric modules and vapor-compression refrigeration enable precise temperature control across a wide range of operating conditions (Figure 2b).

Figure 2. Below: In passive cooling designs (left), the laser heat increases until the equation is satisfied. In active cooling designs (right), the laser temperature is controlled. Courtesy of Aspen Systems LLC.

Despite this large range of cooling methods, the status quo for laser cooling has been largely unchanged for many decades, dating back to when the first lasers were cooled with chilled-pumped loop systems.

Within industry, the development of a miniature variable-speed compressor marked a turning point. The company Aspen Systems LLC pioneered this mechanism, initially designing it for demanding military applications where size, weight, capacity, power efficiency, and reliability are paramount. Though it is 10× smaller and lighter than conventional compressors, the miniature design delivers equivalent capacity (Figure 3). With a turndown ratio of >5:1 and closed-loop proportional-integral-derivative (PID) control, these compressors can maintain laser temperatures within ±0.1 °C across a wide operating range (see the definition of PID below).

Figure 3. Aspen Systems’ miniature variable-speed compressor. Courtesy of Aspen Systems LLC.

This breakthrough continues to chart a course to advance beyond single-speed compressor-based chiller systems toward a more reliable design that eliminates the pumped loop altogether.

Waterless cooling: To the factory floor

Fundamentally, direct refrigerant cooling (DRC) technology overcomes the reliability issues of pumped liquid loops. Instead of circulating coolant water through a reservoir and pump, refrigerant flows

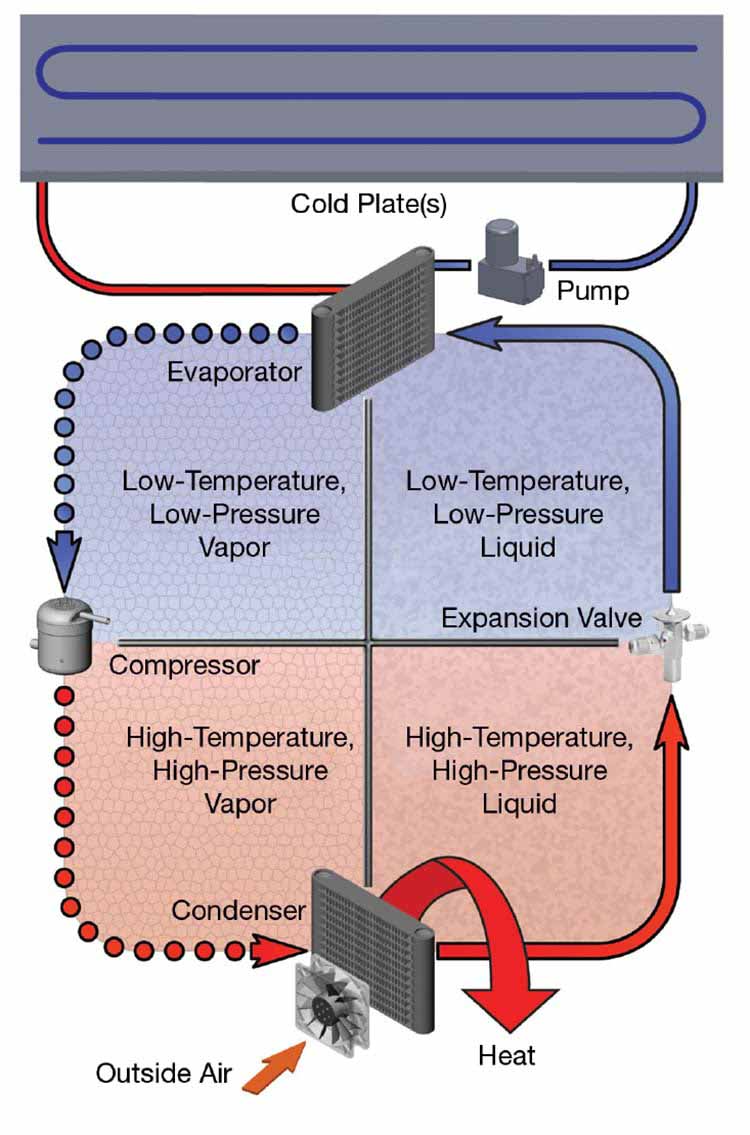

directly through a cold plate in contact with the laser (Figure 4).

Figure 4. The complete DRC system at a glance (top) and in a schematic (bottom). A cooling plate is attached to the laser on one side of the design (top). On the other, a compressor with auxiliary electronics is installed into the laser power supply unit. The pumped liquid loop is missing from the schematic (bottom). A flexible refrigerant line is between the condenser unit and the cold plate, which

enables manipulation of the laser without moving the compressor unit. The cooling plate is isolated from the EKSPLA FemtoLux laser. FemtoLux offerings achieve power stability <0.5% root mean square of >100 h; M2 <1.2 beam quality; burst-mode options in megahertz, gigahertz, or combined; and true pulse-on-demand capability. Optional-harmonic generation modules further expand the wavelength range to 515 nm (20 W, >50 µJ) and 343 nm (10 W, >25 µJ). Courtesy of Aspen Systems LLC and EKSPLA.

Since the approach avoids the need

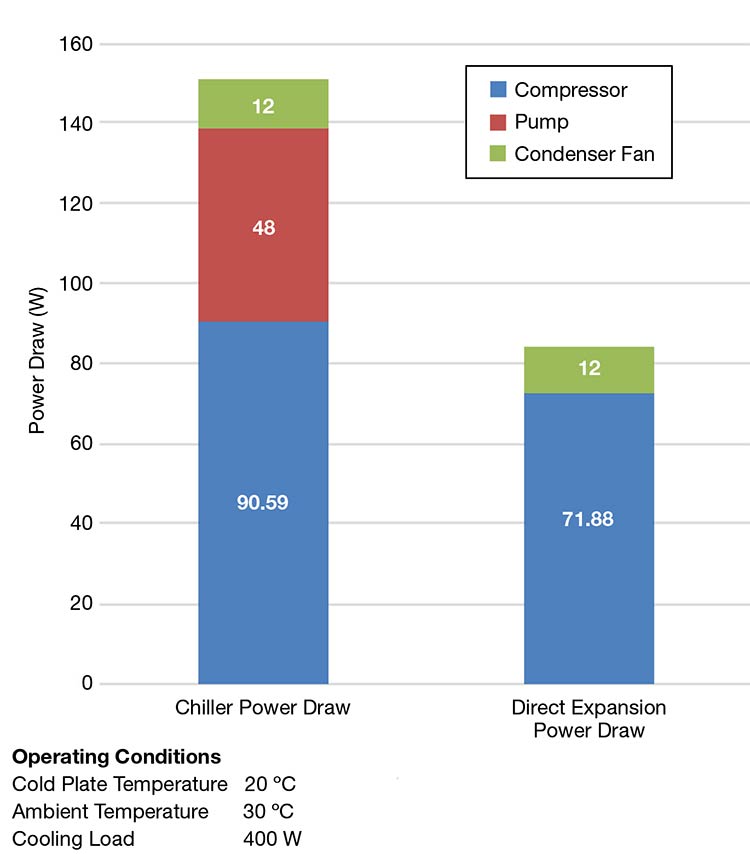

for water, it eliminates any risk of leaks and algae. In addition, it enables a smaller footprint, ~50% greater energy efficiency compared with water-cooled systems, minimal maintenance, and uniform cold plate temperature through isothermal phase-change heat transfer (Figure 5).

Figure 5. Dry refrigerant cooling, or dry cooling, versus the direct expansion method. In comparison, dry refrigerant cooling is 50% more efficient than liquid chilling designs. Courtesy of Aspen Systems LLC.

In comparative tests, direct refrigerant systems consumed half the power of liquid chillers under identical conditions. Compressor lifetime typically exceeds that of a pump by a factor of three to

five.

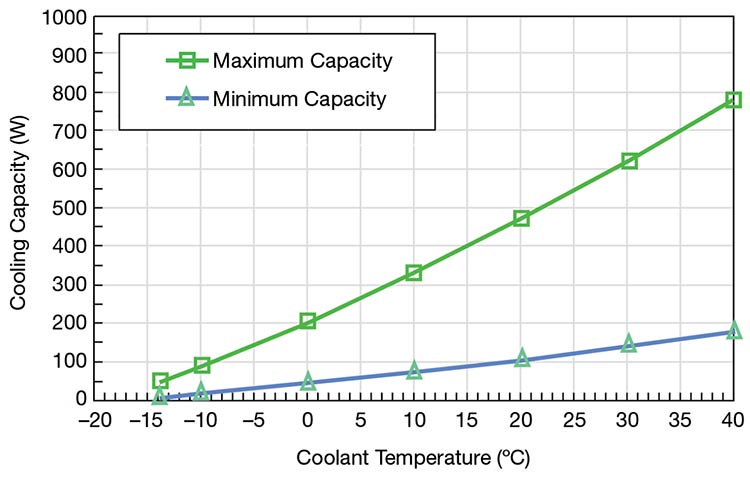

Additionally, temperature control is straightforward: The variable-speed compressor adjusts to meet load demands, keeping the laser temperature within

±0.1 °C across its full operating range (Figure 6).

Figure 6. A typical capacity range of a variable-speed compressor, showing performance across different temperature ranges. Courtesy of Aspen Systems LLC.

DRC for industry

Aspen Systems has deployed miniature compressors in military applications for more than 15 years. Incorporating them into industrial laser systems is an altogether new challenge, placing stringent demands on system design and engineering. Industrial environments may not seem as extreme or rigorous as those in which many military and defense systems operate, but they present a different range of ambient conditions. The military communications equipment, high-power directed-energy systems on ground vehicles, transit cases, and helicopters for which miniature compressors have been effective hardly resemble industrial production settings.

EKSPLA sought to capture the benefits

of the same technology that keeps

mission-critical military systems running for industrial lasing — effectively, delivering battlefield-proven performance

to the laboratory and production floor.

To accomplish this, the company implemented the principles of DRC into its FemtoLux series of industrial femtosecond lasers.

The DRC system integrated into the FemtoLux platform consists of four primary components: a compressor, a condenser, an expansion valve, and an evaporator. A high-pressure refrigerant is delivered to the expansion valve, which is mounted directly on the cooling plate that serves as the evaporator. As the refrigerant expands, it enters the cooling plate as a low-temperature, low-pressure liquid. As it circulates through the plate, it absorbs excess heat from the laser head and

undergoes an isothermal phase transition from liquid to vapor. The resulting

vapor returns to the compressor to be compressed into a high-temperature, high-pressure gas before passing through the condenser. There, the refrigerant

once again condenses into liquid form,

releasing heat to the ambient environment.

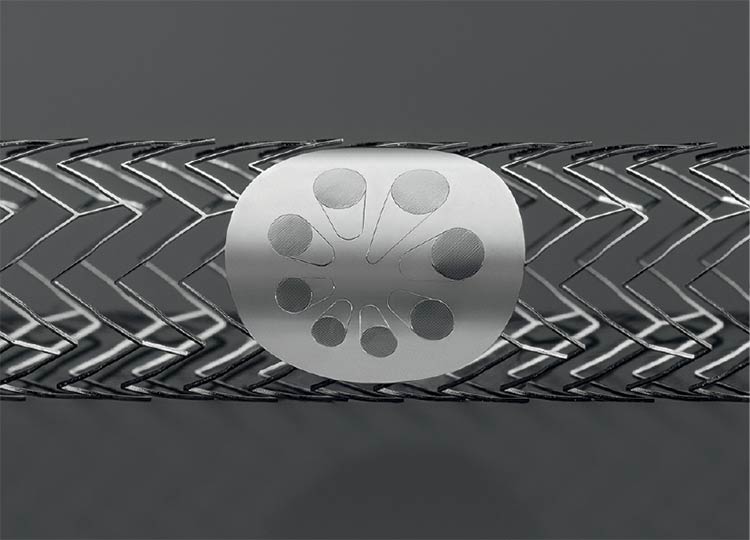

The refrigerant loop enables exceptional integration flexibility, which is necessary to allow the laser head to be placed inside processing equipment or even mounted on a moving stage. It comprises the compressor and condenser, integrated within the power supply unit, as well as the expansion valve/cooling plate bundle, which is connected via 3-m-long armored flexible lines. For convenience, the

cooling plate can be detached from the laser head during integration.

Using a variable-speed compressor serves to ensure reliable operation across diverse environments. By adapting the cooling capacity to ambient conditions, the system removes only the required

heat load, thereby avoiding ΔT-related performance issues.

The approach also accounts for potential issues related to maintenance. Hermetically sealing the refrigerant

circulation loop at the factory, for

example, eliminates the maintenance tasks such as refilling, filter replacement, and/or flushing that are common for water-based systems. And, with a mean time between failures of >90,000 h, the system can operate continuously for more than a decade without downtime.

Further, the integrated DRC solution consumes roughly half the electrical power of a conventional water chiller for the same cooling capacity. The absence of bulky components such as pumps and tanks renders the power supply unit compact; the compressor itself is up to 10× smaller and lighter than traditional equivalents. And the laser head with its cooling plate weighs 32 kg, while the power supply unit with the integrated compressor and condenser adds only

15 kg to the system.

Performance and integrator experience

EKSPLA engineered the FemtoLux series for industrial micromachining applications (Figure 4). For this set of applications, lasers in the series deliver up to 50 W of output power at 1030 nm with pulse durations from <400 fs to 1 ps, and repetition rates ranging from single shot to 2 MHz. In tests, lasers in the series achieved stable operation of >25,000 h. Additional features are included in

Figure 4.

For systems integrators, the addition of the dry-cooling capability represents a major innovation. Integrating and then leveraging an established DRC solution for industrial laser operation eliminates the limitations of water and air cooling. In addition, the simplicity of attaching the cooling plate streamlines laser head integration overall, while the compact power supply unit ensures straightforward installation.

In addition to ease of operation, extensive feasibility studies in application labs have demonstrated the suitability of

FemtoLux for diverse micromachining

tasks. These include stent cutting, semiconductor processing, and precision industrial machining. FemtoLux systems are installed worldwide, including in

settings in which uptime and reliability are essential, such as 24/7 production lines.

Full circle — and beyond

FemtoLux represents the closing of an industry-critical technological loop. Refining, miniaturizing, and adapting a cooling solution originally developed to ensure uncompromising reliability in mission-critical military systems is

powering industrial production lines where efficiency, uptime, and cost control are just as mission-critical.

From battlefield deployments to laser laboratories, and now to industrial

ultrafast laser manufacturing, direct refrigerant cooling has proved to be a robust, efficient, and future-ready technology.

Meet the authors

Laurynas Ukanis, MBA, serves as chief

marketing officer at EKSPLA, where he

oversees international marketing strategy

and fosters the adoption of photonics technologies across industrial and scientific

markets; email: l.ukanis@ekspla.com.

Deividas Andriukaitis, OEM laser sales manager at EKSPLA, specializes in femtosecond lasers and microfabrication, developing tailored industrial laser solutions for advanced applications. He has a master’s degree in laser technology; email: d.andriukaitis@ekspla.com.

Lukas Rimgaila is program manager of FemtoLux lasers at EKSPLA, overseeing the development and commercialization of advanced femtosecond laser solutions tailored for OEM partners and industrial applications; email: l.rimgaila@ekspla.com.

Jim Burnett, director of business development at Aspen Systems, has more than

40 years of experience developing advanced

materials and cooling technologies. He currently facilitates technology discussions with incoming customers; email: jburnett@aspensystems.com.

Direct Refrigerant Cooling: Myths and Misconceptions

The adapted direct refrigerant cooling (DRC) approach often faces concerns. Among the most prevalent are:

• DRC uses F-gas refrigerants with high global warming potential.

FemtoLux series lasers use a low-global-warming potential refrigerant approved for transport and laboratory use. DRC’s associated power consumption is about half that of a system using a water chiller and up to 8× lower than that of a system using a thermoelectric cooler.

• The compressor generates vibration that affects laser performance.

The compressor is housed in the power supply unit, isolated from the laser head, and produces less vibration than water pumps or air-cooling fans. Stability tests on the FemtoLux series confirmed that output power stability parameters meet or exceed industry standards.

• Condensation forms on the laser due to DRC.

Condensation risk is present with any cooling system, and the FemtoLux series mitigates this with a variable-speed compressor. The compressor delivers only the required cooling power, preventing excessive ΔT that could cause condensation.

• DRC is new and lacks a track record.

DRC has been used for more than a century, powering applications from household refrigeration to automotive air conditioning. It is simply cooling technology without the use of pumped liquid lines. The technology is also battlefield-tested and used in military systems, including those that are deployed in helicopters, ships, armored vehicles, and more. EKSPLA’s FemtoLux adapts this principle for industrial lasing use cases.

Nitinol stent cutting using a direct refrigerant cooling (DRC) EKSPLA FemtoLux system (top). Aspen Systems’ refrigeration systems, as used in military applications (bottom). Courtesy of Vactronix Scientific (top) Aspen Systems LLC (bottom).

/Buyers-Guide/EKSPLA/c4157

/Buyers-Guide/Aspen-Systems/c30563