UAV vision systems are increasingly important in mapping, surveying, photogrammetry, and agricultural inspection, featuring lenses capable of handling higher levels of pressure, temperature swings, and vibration.

CORY BOONE, EDMUND OPTICS

Machine vision systems are no longer confined to factory automation. Today, this technology is found in mobile robotics, such as autonomous agriculture equipment, cars, and drones. These applications push high-resolution imaging lenses into environments outside of traditional machine vision settings, which include harsh conditions beyond those that these lenses were originally designed for (Figure 1).

Figure 1. Imaging lenses for high-resolution uncrewed aerial vehicle (UAV) systems face demanding environments

beyond those compatible with both traditional machine vision lenses and the small, cheap lenses used for consumer drones. Courtesy of Edmund Optics.

High-resolution uncrewed aerial vehicle (UAV) imaging has become increasingly important for mapping and surveying, photogrammetry, agricultural inspection, and more, but the lenses in these systems face a vastly different environment than traditional machine vision lenses.

They are exposed to challenging levels of pressure, temperature swings, and shock and vibration. Both conventional machine vision lenses and the small, cheap lenses conventionally used with consumer drones can meet the demanding requirements of fixed-wing UAVs and other high-performance robotics systems. Because of this, new generations of lenses are being tailored specifically for these newer, high-performance UAV applications.

Unique application requirements

The imaging system in a UAV is critical for proper positioning, guidance, and data gathering. Aerial imaging with UAVs can be used to inspect large land areas, assess a given environment, and obtain useful data. Photogrammetry and multi- and hyperspectral imaging are two notable use cases for UAV imaging.

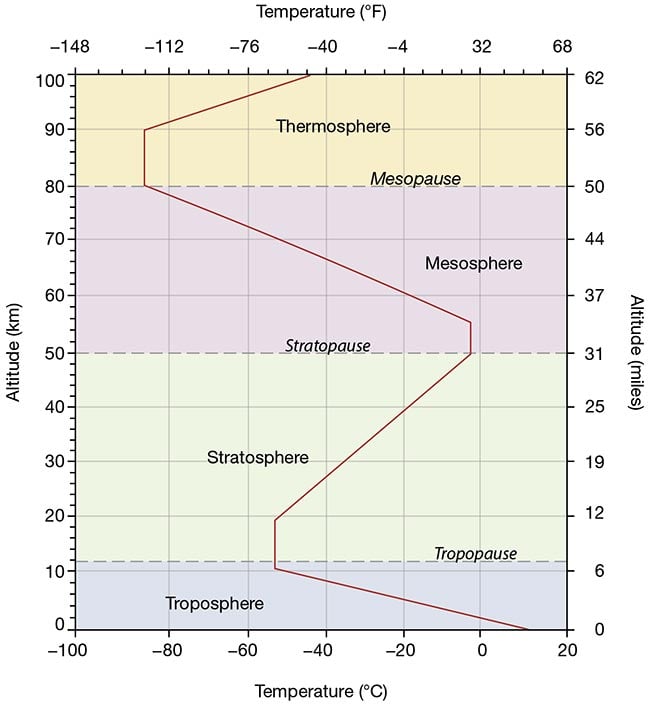

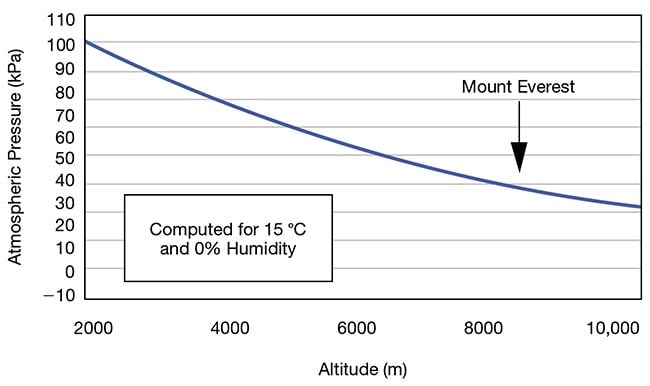

Photogrammetry generates 3D maps of areas by combining many overlapping 2D images. An important parameter for this is the UAV’s ground sample distance (GSD), which is the distance on the ground between the pixel centers of the sensor. GSD is related to the best possible spatial resolution of the imaging system and objects being imaged, also known as the Nyquist frequency. Improving the system’s GSD allows the UAV to reach higher altitudes, leading to a wider field of view. As a result, fewer photos must be taken, which increases efficiency. Military UAVs are currently able to fly up to altitudes of 50,000 ft, or 15.2 km, which introduces significant environmental challenges for their imaging systems. The temperatures and pressures that they experience can vary between ~30 to −50 °C and 100 to ~20 kPa, respectively (Figures 2 and 3).

Figure 2. Variations in the temperature experienced by uncrewed aerial vehicles (UAVs) with respect to altitude. Courtesy of Edmund Optics.

Figure 3. Variations in the pressure experienced by uncrewed aerial vehicles (UAVs) with respect to altitude. Courtesy of Edmund Optics.

These harsh conditions, along with shock and vibration, can result in the elements of the lens assembly decentering and shifting. This reduces resolution and makes the imaging system the limiting factor in overall system performance, which makes the environmental ruggedization of imaging lenses particularly important for photogrammetry.

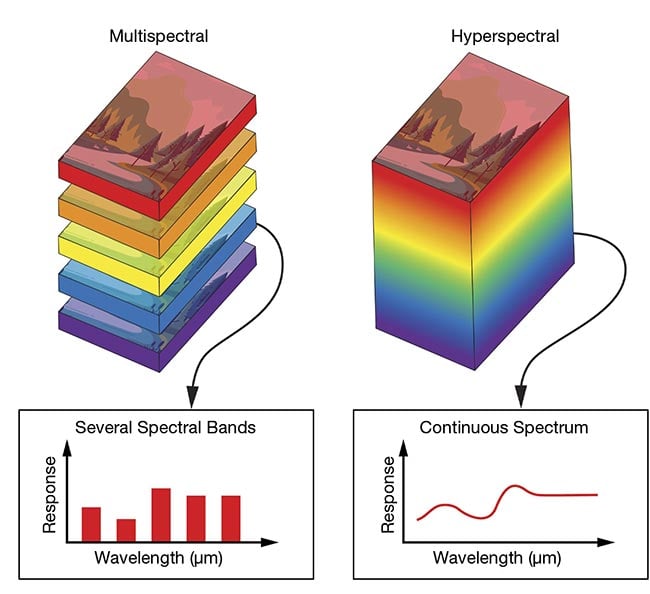

Multi- and hyperspectral imaging is an important use case of UAV imaging and is important for agricultural and environmental surveying. Multispectral imaging involves capturing images in multiple wavelength bands, while hyperspectral imaging involves capturing images over a single, large, continuous wavelength range (Figure 4). Many types of crops and other vegetation show vastly different properties at certain wavelengths outside of the visible spectrum.

Figure 4. The difference between multispectral and hyperspectral imaging is whether wavelength information is represented discretely or continuously, respectively. Courtesy of Edmund Optics.

The importance of GSD for photogrammetry is still a factor here, but multi- and hyperspectral imaging have an additional important dependence on broadband wavelength transmission and detection. This further complicates the requirements of the optics, requiring optical designers to balance a broad wavelength range, environmental ruggedization, and high resolution. The smallest size of wavebands that the system can differentiate is its spectral resolution. Multispectral imaging has a lower spectral resolution than hyperspectral imaging because it is not imaging over a continuous waveband, making it simpler to design and usually less expensive. The exact technique of spectral imaging that is required varies between specific use cases.

UAVs are finding increasing application in military situations for surveillance, target decoys, and general combat missions. And in the commercial space, UAVs are revolutionizing data gathering methods for mining, disaster relief, and archeology by using similar concepts as those described in the previous section on photogrammetry. They can increase data gathering efficiency, saving time and labor.

History of UAV imaging lenses

When machine vision systems were introduced for factory automation, C-mount lenses from the security market were repurposed for these new applications. Similarly, lenses from factory automation have been repurposed for the growing UAV and autonomous mobile robot space. However, these lenses are not ideal for these mobile robotics systems because they were designed for completely different operating environments.

UAV machine vision systems are pushing to increasingly high resolutions by taking advantage of new, high-resolution image sensors, such as the fourth-generation Sony Pregius 1.2-in. IMX530 and IMX540 sensors. But unfortunately, the C-mount lenses from factory automation that can fully use these sensors are too large, heavy, and susceptible to performance degradation from the harsh environments of UAVs to be effective. Also, the tiny, compact lenses that are typically used in consumer drones cannot achieve the high performance required to take full advantage of these newer sensors.

Fortunately, a new generation of high-resolution lenses designed specifically for high-performance UAVs and other mobile robotics has been introduced. Their streamlined design maintains the high resolution needed for those newer sensors while reducing the size and weight relative to traditional factory automation lenses.

Locking focus and iris rings prevent unwanted adjustments during use. These lenses are also optimized for longer working distances, because UAVs and other mobile robots are often focusing on objects farther away than what is typically found on a factory floor. Extra care is taken to minimize stray light throughout the lens assemblies, which is important because the conditions experienced by UAVs are much less controlled than those on a factory floor.

Environmental ruggedization

High-resolution lenses are environmentally ruggedized to maintain pointing stability and high resolution in the demanding environments of high-altitude UAVs.

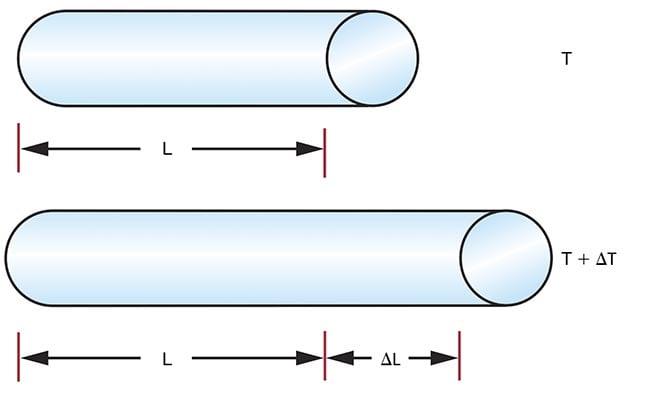

Temperature changes cause shifts in the physical size of objects at a rate dependent on their coefficient of thermal expansion (CTE), and the different CTEs of glass and metal cause them to expand and contract at different rates (Figure 5).

Figure 5. Temperature changes (ΔT) lead to a change in the length of a material (ΔL) based on the material’s linear coefficient of thermal expansion

(CTE). But this expansion occurs in all three spatial dimensions, not only linearly in one dimension, as shown here in

this simplified illustration. Courtesy of Edmund Optics.

The CTE mismatch between the glass and metal in an imaging lens introduces the potential for elements in the assembly to shift, tilt, or become misaligned, and even crack as they experience temperature swings. The lens elements’ refractive index also shifts with temperature, but this effect typically affects system performance less than the change of physical size due to thermal expansion and contraction. This enhances the importance of reducing the shift in the lens assembly elements and the lens’ sensitivity to misalignment.

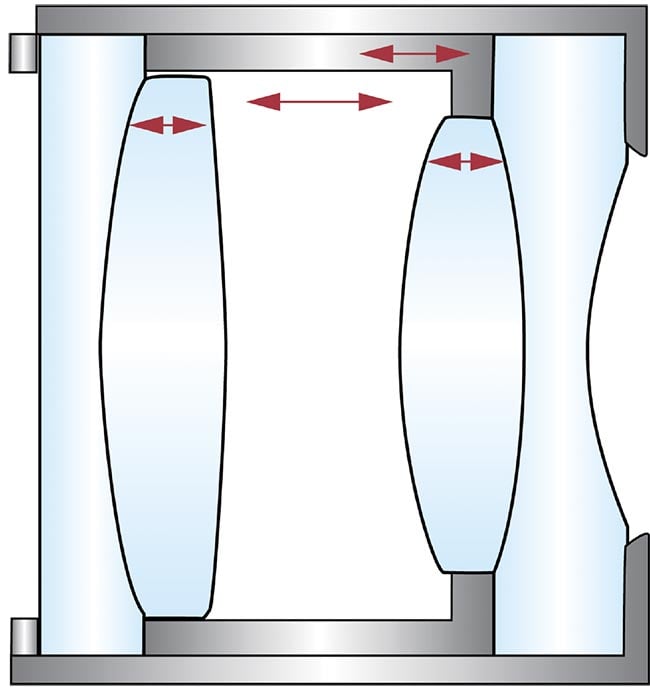

The new generation of UAV lenses has their assembly designed so that different elements compensate for each other’s expansions and contractions, minimizing the misalignment of individual elements because of thermal effects (Figure 6). These athermalized designs are more rigorous and time-consuming to create, but they maintain consistent performance across a given temperature range.

Figure 6. Shrinking and growing compensations of a rigorous athermal design. Courtesy of Edmund Optics.

Changing pressure due to altitude changes must also be considered when designing lenses for UAV systems. During the optical design process, the air inside and outside the lens is modeled at different pressure values using simulation software to predict the effects on the lens’ performance. This results in a final design that can tolerate these shifts in pressure.

The quick accelerations experienced by UAVs also require the assemblies to be ruggedized to maintain pointing stability throughout shock and vibration. This means that a spot on the object being imaged will consistently map to the same point on the image sensor. This type of ruggedization is performed by streamlining the lens’ optomechanics, reducing the number of moving parts in the assembly, and adding adhesives around individual lens elements to prevent them from shifting and throwing off pointing stability.

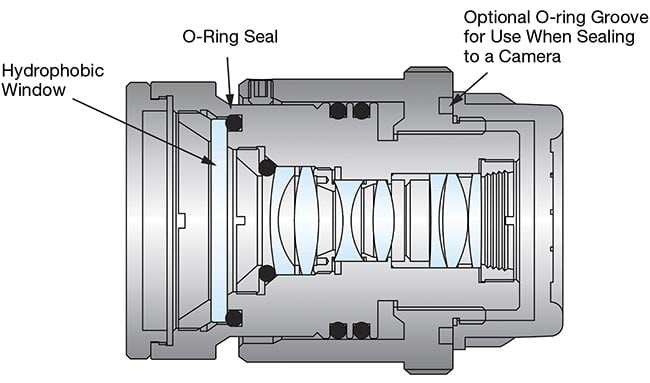

Finally, ingress protection might be required to seal off the lens and prevent particulates and moisture from getting into the assembly. The performance of the system can be reduced by dust and water entering the lens because light hitting these particulates is scattered throughout the assembly. Sealing the internal workings of the lens from the outside world using O-rings or purging the air inside of a lens during assembly and replacing it with an inert gas prevents this performance degradation (Figure 7). This purging process removes particulates from inside the lens and does not allow new particulates to penetrate it.

Figure 7. Ingress-protected lenses are sealed to prevent moisture, dust, and other contaminants from entering the assembly. Courtesy of Edmund Optics.

This sealing also prevents condensation from forming on the internal lenses. If humidity enters the assembly, water particles can very easily adhere to the lens and redirect the light hitting it. This significantly worsens system performance and is a problem when imaging at low temperatures, such as those at high altitudes. Figure 7 shows that this condensation can be further prevented with a hydrophobic window on the front of the external lens surface.

Advancing UAV imaging

This new generation of UAV lenses allows UAV system designers to push into previously unrealistic levels of altitude and resolution. High resolution is balanced with a lightweight design and environmental ruggedization, making them ideal for drone mapping and surveying, aerial imaging, and photogrammetry applications. Purchasers should talk to their imaging lens supplier about how to best tailor lenses for the unique requirements of their UAV imaging applications.

About the author

Cory Boone is the technical marketing manager at Edmund Optics, where he leads the creation of technical marketing communications. Boone has a decade of experience in the optics industry, received a Bachelor of Science in optical sciences and engineering from the University of Arizona, and has a Certified Vision Professional (CVP) Basic certification from the Association for Advancing Automation; email: [email protected].