Photonics HandbookTechnology News

Dual-Property Coating Combats Fog, Reflections at Same Time

Researchers from the Fraunhofer Institute for Applied Optics and Precision Engineering IOF (Fraunhofer IOF) and Friedrich Schiller University Jena developed an optical coating system that combines antifogging (AF) and antireflective (AR) properties. The dual-property technology could help boost the performance of lidar systems and cameras, such as those used in autonomous vehicles.

“Walking into a warm room from the cold outside can cause glasses to fog up, blinding the user,” said research team leader Anne Gärtner from Fraunhofer IOF and Friedrich Schiller University Jena. “The same can happen to sensors such as the lidar systems used in autonomous cars. It is important that surfaces remain highly transparent, even if fogging occurs, so that functionality is maintained.”

The researchers developed the coating system in response to a need identified by Leica Geosystems, a developer of airborne lidar measurement systems that are used for terrain and city mapping. When there are extreme temperature differences between the environment and the measuring system, fogging sometimes occurs on the optical surfaces, impairing functionality.

Members of Gärtner’s team collaborated with Leica Geosystems to develop a solution that managed the fogging as well as undesirable light reflections. They combined a polymer coating that prevents fogging with porous silicon dioxide nanostructures that reduce reflections.

“We used a polymer that prevents fogging on an optical surface by acting as a water reservoir,” Gärtner said. “However, differences in the refractive indices of the polymer material and the surrounding air leads to unwanted reflections and ghost light. To prevent these reflections, we combined the antifog film with very small structures — up to 320 nm high — to create an antireflective effect together with water permeability.”

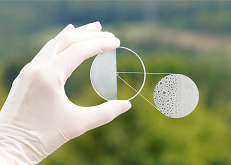

Researchers working in an industry-academia partnership developed a combined antifogging and antireflective double nanostructured coating system. The coating is poised to benefit applications that range from quantum science to lidar for autonomous vehicles. Courtesy of Fraunhofer IOF.

Work to develop the coating system to Leica’s specifications required that nanostructures with antireflective properties achieve a level of reflectance that would be comparable to that of conventional interference coating systems for the specified range of incident light angles, Gärtner told Photonics Media.

The researchers applied the patented AR-plas2 technology developed at Fraunhofer IOF. AR-plas2 process technology allows several nanostructures to be created on top of each other. The process involved etching a nanostructure into the antifog coating and then fabricating a second nanostructure on top. With this technology, it is possible to adjust the refractive indices of the nanostructures to tailor the design of the double nanostructure to achieve very low reflection over a wide spectral range.

The researchers tested the antireflection and antifog effects of their coating system using reflectance measurements acquired with a spectrophotometer and fogging measurements obtained after holding the antireflection/antifogging side of the optic over heated water. These laboratory tests showed that the multilayer system exhibited very low reflection over a wide spectral range, which would be impossible with a single nanostructure. In addition, the nanostructures did not affect the coating’s antifog properties.

Because the structures are generated in a standard plasma-ion-assisted coating machine, the new approach can be easily incorporated into commercial manufacturing processes.

Though the researchers did not design the coatings specifically for lidar systems, the technology can be tailored for many different applications. AR-plas2 technology can be applied to almost all types of materials, including polymers, as well as to glass or fluoride crystals. It is therefore widely applicable: for optics in lighting, for example; in the automotive and consumer goods sectors; and in future technologies such as quantum computing. In addition to being applied in several lidar prototype systems, the coating technology is already being used in cutting-edge smartphone cameras.

Gärtner told Photonics Media that the coating system has been successfully used in a prototype for a lidar application by Leica Geosystems. Beyond laboratory tests, the system demonstrated good results in field tests, she said.

“Further long-term stability tests will be carried out in 2023 depending on the weather conditions,” she said. “If modifications to the AR/AF-system are necessary, they can be made on a short timeline. A serial production can be expected for 2024.”

“Optical systems are becoming more and more complex, and thus the demands on image quality are also increasing,” Gärtner said. “With nanostructures, antireflective properties can be achieved with impressive results that are often not feasible with conventional coatings. With the fundamental understanding we gained over the recent years, we are confident that we can bring nanostructured coatings to many real-world applications.”

The research was published in Applied Optics (www.doi.org/10.1364/AO.476974).

/Buyers_Guide/Leica_Geosystems_AG/c30772