Full company details

Hamamatsu Corporation

Sub. of Hamamatsu Photonics K.K.

360 Foothill Rd.

360 Foothill Rd.

Bridgewater, NJ 08807

United States

Phone: +1 908-231-0960

Fax: +1 908-231-1539

Demand for MIR Photonics Rises on New Gas Analysis Applications

Photonics Spectra

Jan 2022MIR sources and detectors are introducing improved form factors, performance, cost, and compliance — just in time to meet demand from the expanding market for gas analysis.GARY SPINGARN, HAMAMATSU

As MIR LEDs have become more powerful and efficient sources, an emerging generation of compact MIR detectors is offering effective performance at room temperature. Together, these developments are enabling gas analysis techniques that leverage LED-based nondispersive infrared (NDIR) detectors. One of the fastest-growing markets for NDIR systems is methane detectors. Methane not only poses safety and environmental concerns, but methane gas leaks are just bad for business. Courtesy of Hamamatsu.

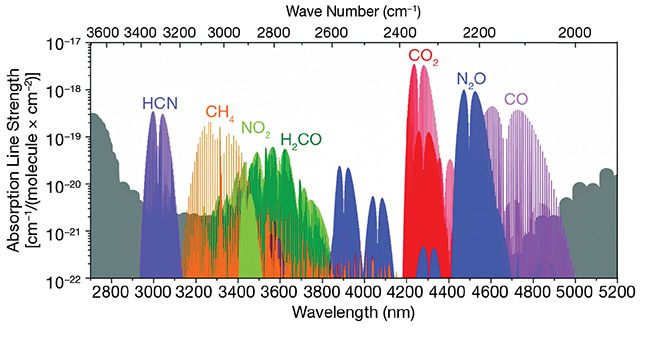

Real-time precision gas analysis is critical to a wide range of industries, including medical diagnostics, emissions monitoring, and semiconductor fabrication. The relatively simple molecular structure of most gases makes them ideal candidates for absorption spectroscopy. Infrared (IR) absorption is especially useful since this spectral region corresponds directly to a molecule’s unique vibrational modes (Figure 1), providing exceptional sensitivity and specificity.

Figure 1. Infrared absorption is especially useful in the MIR range because this spectral region corresponds directly to the unique vibrational modes of gases such as carbon dioxide, carbon monoxide, and nitrous oxide. Courtesy of Hamamatsu.

With new developments and innovations making IR components more accessible, it should come as no surprise that the IR gas sensor market is projected to more than double to $288 million by 2026, from an estimated $132 million in 2021

1.

Due to their low cost and broad spectral coverage, IR sensors have historically relied heavily on thermal technologies, including blackbody emitters and thermopiles. Even today, some engineers remain apprehensive about adopting photonics technologies such as quantum cascade

lasers (QCLs), solid-state light-emitting diodes (LEDs), and photodetectors targeting the mid-IR (MIR). Fortunately, concerns related to cost, power, and packaging are starting to wane, leading to a revitalization of the gas sensing industry as the mid-IR market continues to mature.

QCLs for gas sensing

Historically, QCLs have high power consumption. However, with innovations in packaging and chip structure, their lasing thresholds have come down more than 50%, with some lasers able to begin operating with only 250 mA. These new packages can be produced at lower cost and in high volume. Modern QCL modules can also come pre-packaged with integrated collimating lenses, temperature controllers, and laser drivers, making them easier to integrate into a final assembly.

Most engineers are familiar with the advantages of an integrated thermoelectric cooler, especially with respect to wavelength and power stabilization. Fewer realize the extent to which an integrated lens can pay dividends in terms of system design. Collimating laser output with micro-optics closer to the output facet not only requires fewer external optical components, but it also eases optimization of the path length by reducing beam divergence and astigmatism.

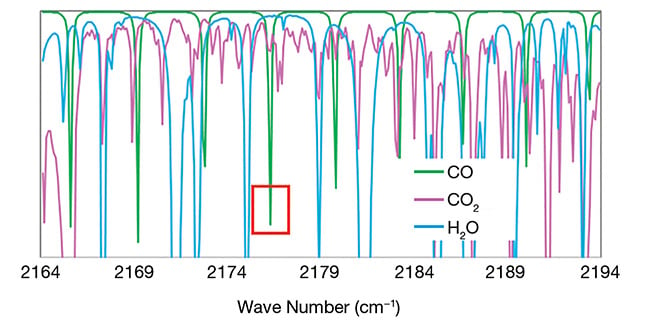

One crucial advantage for QCLs is that they can achieve an extremely narrow linewidth, which allows users to zero in on narrow absorption lines. Consider an open atmosphere gas analyzer measuring carbon monoxide. If, for example, a broad band emission source measures absorption around 4.6 µm, the sensor would experience interference from the nearby water and carbon dioxide bands (Figure 2). A single-frequency QCL, however, can be tuned to the exact carbon monoxide absorption peak around 2175 cm

–1. Not only does this result in lower background interference, but because all of the laser’s energy falls within the absorption band, the overall instrument’s signal-to-noise ratio improves by several orders of magnitude. Furthermore, the output of a QCL can easily be collimated to allow for longer optical path lengths compared to broadband emitters. This further enhances the signal-to-noise ratio.

Figure 2. A single-frequency quantum cascade laser can be tuned to the exact carbon monoxide absorption peak around 2175 cm–1. Not only does this result in lower background interference, but because all of the laser’s energy falls within the absorption band, the overall instrument’s signal-to-noise ratio improves by several orders of magnitude. Courtesy of Hamamatsu.

Semiconductor fabrication

The semiconductor supply chain is currently under heavy pressure, which has opened the door to an expanding role for gas analysis in wafer and chip production. Cleanrooms have made leaps and bounds in minimizing the risk of contaminants to the fabrication process, but the industry still struggles with outgassing and tool leakage. Trace impurities on the order of parts per billion, and in some cases parts per trillion

2, can create defects on a wafer that can, in turn, adversely affect chip quality downstream. Therefore, as performance standards for semiconductor

chips continue to increase, so does the demand for high-quality trace gas analyzers. Many absorption bands of gas phase contaminants — such as hydrogen chloride, ammonia, hydrogen fluoride, and hydrogen sulfide — lie in the MIR range between 3 and 10 µm, making QCLs the optimal light source to probe for these substances.

Another benefit that QCLs provide is the capability for continuous monitoring. Today’s lasers can comfortably operate in a continuous-wave (CW) or quasi-CW mode for hours, allowing them to provide readings in real time. This feature is critical for the real-time process control and monitoring required in today’s 24/7 fabrication environments. At a time when a single wafer cannot be spared, process and quality control become paramount.

Emissions monitoring

Many will remember the 2015 “defeat-device” scandal, in which an automaker disabled the emissions controls in its diesel-engine fleet vehicles. It was only through cutting-edge gas analysis techniques that the real emissions of these vehicles were properly quantified. Conventional testing apparatus would require cars to be in a stationary lab. So it is only through inspections that problem vehicles can typically be identified. Because major smog contributors, such as nitrogen oxides and sulfur oxides, have strong absorption bands between 6 and 9 µm, QCL-based systems now enable portable and standoff emission monitoring systems

3.

Measuring emissions is challenging because automotive exhaust fumes contain multiple gases and, frequently, particulates. Emission analysis is also affected by other environmental variables, such as temperature and humidity.

As Figure 2 illustrates, the nature of QCL-enabled gas analysis sensors allows them to dodge potential sources of interference and pinpoint key absorption peaks. As more portable analyzers are deployed, such gas sensors can identify vehicles that fail regulations on the road and at weigh stations and provide real-time monitoring of air conditions.

Solid-state LEDs and detectors

Even though cost, power consumption, and ease of use have dramatically improved for QCLs, certain high-volume applications are still not within their reach. Fortunately, recent developments in MIR LEDs have made them more powerful and efficient sources for this band while maintaining their trademark low power consumption and long operating life.

Additionally, an emerging generation of mass-producible MIR detectors can perform effectively at room temperature. For decades, these devices required cooling, and their cost remained out of reach. New MIR detector packages are also being designed to maintain performance while resisting temperature variance.

These developments are enabling gas analysis techniques that leverage the LED-based nondispersive infrared (NDIR) technology. There is a wide variety of NDIR cells, but they are all based on the same fundamental principle: They integrate a light source with a detector across a fixed optical path length to determine gas concentrations via Beer’s law

4.

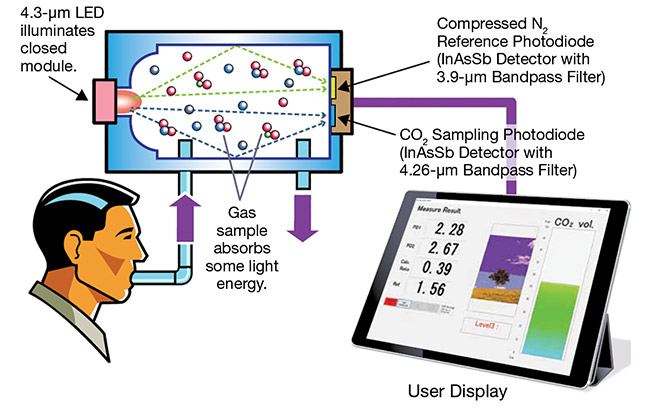

Typically, NDIR cells (Figure 3) use differential absorption by incorporating a dual-channel detector with one or more MIR light sources. The reference signal serves as a baseline and, in many designs, has helped manage noise and increase accuracy at minimal cost. As the analyte increases, the response from the measurement and reference detectors converges, resulting in a direct correlation between detector voltage and gas concentration. Components for these systems are now cost-effective, conveniently packaged, and primed for high-volume production.

Figure 3. LEDs can be used for NDIR detection techniques, which integrate the LED along with a reference and sampling photodiode. Courtesy of Hamamatsu.

Methane leaks

One of the fastest-growing markets for NDIR systems is methane detectors. Methane not only poses safety and environmental concerns, but methane gas leaks are just bad for business. In high-volume optical leak detection, designs based on LEDs are a great choice because, unlike thermal sources, an MIR LED has peak emission at a given wavelength that is targeted for a particular species such as methane.

The gas heavily absorbs light at 3.3 µm,

but several other light hydrocarbons also exhibit absorption characteristics nearby. This invites the integration of multiple filtered detector channels into a single NDIR cell to simultaneously detect a variety of fuel gases. The small form factor and low power consumption of LED-based NDIR instruments allows them to be deployed in a distributed network across multiple points of operation. NDIR technology further provides the sensitivity required to compete in the cost-sensitive energy market where economy of scale is a must.

Capnography

Capnography, the active measurement of exhaled carbon dioxide, remains a key source of metrics for many medical applications. Accurate capnography readings are essential during anesthesia and emergency medical transport, and they are instrumental for the operation of continuous positive airway pressure (CPAP) therapy machines and for monitoring sleep and digestive health.

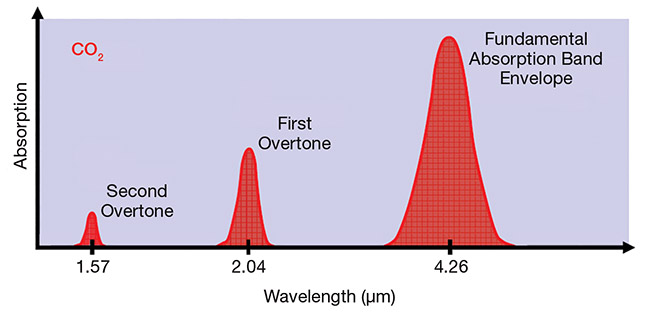

In today’s market, it is extremely common for capnography instruments to rely on IR optical technology, and for good reason. Although carbon dioxide has

absorption bands in the near-IR region, the band near 4.26 µm is orders of magnitude stronger, providing higher sensitivity (Figure 4) and reducing overall design complexity and performance requirements of system components. The smaller form factor of IR instruments also offers benefits when it comes to moving equipment closer to the patient.

Figure 4. Carbon dioxide has absorption bands in the near-IR, but the band near 4.26 µm is orders of magnitude stronger. Courtesy of Hamamatsu.

The future of MIR

With sleeker packaging and lower power consumption, product integration will become increasingly common for QCL technology. As production volume increases for these lasers, they are becoming more accessible than ever — mirroring a similar historic trend seen with vertical-cavity surface-emitting lasers (VCSELs). Once nonviable due to their cost and production challenges, VCSELs today see annual production volumes in the millions. If current QCL offerings are not feasible for an application today, they will be soon.

Likewise, MIR LEDs and detectors are finally available in surface-mount packaging, which offers form factor benefits as well as cost savings. Additionally, while certain photonic detectors require exceptions to the Restriction of Hazardous Substances (RoHS) Directive — due to incorporation of materials such as lead, mercury, and cadmium — there are now alternative chemistries incorporating indium, arsenic, and antimony (InAsSb) that are fully RoHS compliant.

Current trends in gas analysis point to a new era for growth. Concurrently, MIR technologies continue to migrate from niche to mainstream as they overcome production hurdles and improve in form factor, performance, cost, and compliance. The convergence of these trends poses new photonics solutions for meeting emerging market demands. If a problem can be solved by detecting a certain gas, then MIR might present a solution.

Meet the author

Gary Spingarn is product manager at Hamamatsu, where he is responsible for establishing market strategy for MIR products and for advancing long-term projects. He influences product development through analyzing market trends and expert opinions and research, as well as identifying new applications and business opportunities; email:

[email protected].

References

1. Yole Développement (2021). Gas and

particle sensors: technology and market trends 2021,

www.i-micronews.com/products/gas-and-particle-sensors-technology-and-market-trends-2021/?utm_source=pr&utm_medium=email&utm_campaign=pr_gas_particle_sensors_yole_july2021.

2. W. Den et al. (2006). Organic airborne molecular contamination in semiconductor fabrication clean rooms: a review.

J Electrochem Soc, Vol. 153, Issue 2, pp. G149-G159.

3. R. Suarez-Bertoa et al. (2016). On-road measurement of NH3 and N20 emissions from a Euro V heavy-duty vehicle.

Atmos Environ, Vol. 139, pp. 167-175.

4. D. Popa and F. Udrea (2019). Towards

integrated mid-infrared gas sensors.

Sensors, Vol. 19, p. 2076,

www.doi:10.3390/s19092076.